Excerpt:

The liquid resistance starter cabinet is designed to provide smooth and controlled starting of motors using liquid resistance technology. It reduces starting current, prevents mechanical stress, and ensures reliable and safe motor operation in industrial applications.

Liquid Resistance Starter Cabinet: Ideal Smooth Start Solution for Medium and Large Motors

01 Product Overview

The Liquid Resistance Starter Cabinet is an advanced starting solution designed for medium and large wound-rotor asynchronous motors. It provides smooth, low-impact starting by inserting specially formulated liquid resistors into the rotor circuit and adjusting electrode positions to vary resistance.

This system effectively addresses the drawbacks of traditional starting methods such as direct-on-line or autotransformer start, including high starting currents and severe mechanical stress, ensuring safe and efficient motor start-up.

02 Working Principle & Technical Features

1. Intelligent Starting Principle

The liquid resistance starter operates by inserting a liquid resistor into the motor rotor circuit. Upon receiving a start command, a small servo motor moves the electrodes, gradually reducing resistance.

Once the resistance reaches the minimum, the shorting contactor closes, directly connecting the motor rotor star point. This allows the motor to start smoothly with low current and high torque, minimizing grid impact.

2. Advantages of Liquid Resistance

- Stepless Adjustment: Resistance can be adjusted continuously by changing electrode distance or electrolyte concentration.

- High Thermal Capacity: Can perform 5–10 consecutive starts.

- Low Starting Current: ≤1.3× rated current for wound-rotor motors.

- Wide Voltage Adaptability: Can start even if supply voltage drops 10% below rated value.

03 Core Structure & Design Innovations

1. Modular Design

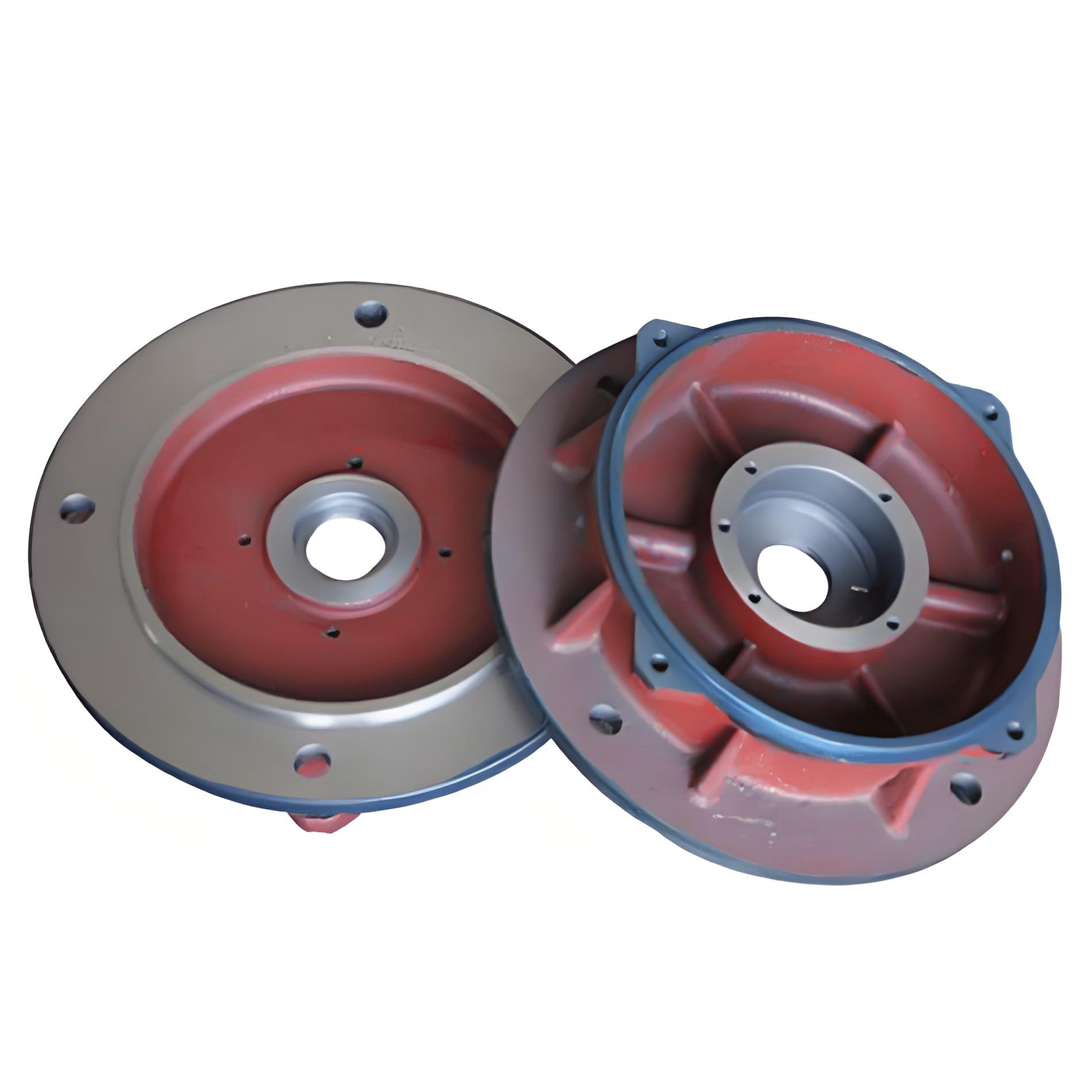

The cabinet features a modular design consisting of:

- Cabinet Structure: Welded steel frame with reserved space for hydraulic and electrical components.

- Liquid Resistor Tank: Houses liquid resistors and fixed electrodes; soft start is achieved by controlling electrode spacing.

- Electrical Compartment: Contains low-voltage control and protection components.

- Drive Mechanism: Typically uses a worm gear system for smooth, quiet operation.

2. Fully Enclosed Innovative Design

- Sealed System: Prevents electrolyte evaporation with precision sealing of all joints.

- Self-Circulating Cooling: Equipped with circulation pumps and internal piping to dissipate heat effectively.

- Environmental Adaptability: Suitable for dry climates with annual precipitation below 200mm, ensuring reliable operation.

04 Performance Features & Advantages

- Constant Current Soft Start: 2.5–3.5× rated current for cage rotor motors, reducing start-up heating.

- Smooth, Shock-Free Start: Minimizes mechanical stress, extending motor and equipment life by ~30%.

- High Start Success Rate: Unaffected by voltage fluctuations or load changes.

- Minimal Grid Impact: Low voltage drop, no harmonic pollution.

- Easy Operation & Maintenance: Fully automated, simple installation, and maintenance.

Compared to conventional oil-immersed, iron, or variable resistor starters, the liquid resistance starter offers superior start performance, reliability, and lifespan, and is simpler and maintenance-free compared to high-voltage soft starters.

05 Application Fields

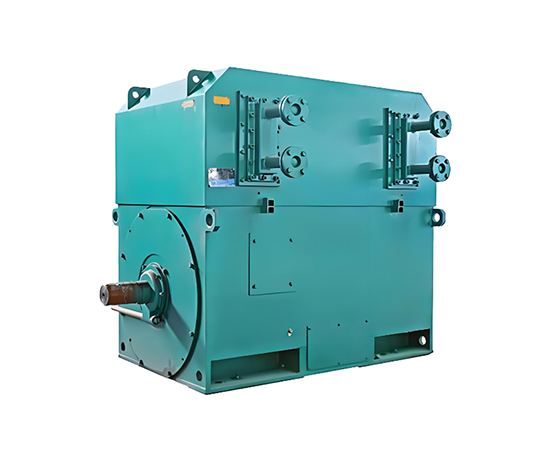

- Heavy Industry: Cement, metallurgy, mining, petroleum, chemical sectors for 75–10,000 kW wound-rotor motors.

- Power & Water Industry: Auxiliary equipment in power plants, large pumps, compressors.

- Special Conditions: Continuous multi-start applications, unstable or low-voltage grids.

Commonly used for ball mills, crushers, compressors, fans, and other heavy-load equipment.

06 Technical Specifications

| Parameter | Specification |

|---|---|

| Applicable Motor | Wound-rotor asynchronous motor, squirrel-cage motor |

| Rated Voltage | 380V–12kV |

| Power Range | 75kW–10,000kW |

| Starting Current | ≤1.3× rated current (wound rotor), 2.5–3.5× rated current (squirrel cage) |

| Starting Time | 10–120 seconds, adjustable |

| Ambient Temperature | -25℃–+50℃ |

| Protection Level | IP20–IP54 |

07 Selection & Installation Guidelines

Selection Considerations

- Motor model, rated power, rotor voltage/current, and rated speed.

- Load characteristics and working conditions.

- Installation environment requirements.

- Appearance and cabinet color preferences.

Installation Environment

- Stable, vibration-free location.

- No corrosive gases or explosive hazards.

- Tilt ≤5°.

- Three-phase AC 380V±10%.

- Special adaptations for temperatures < -5℃ or altitudes >2000m.

08 Maintenance & Troubleshooting

- Regular Checks: Ensure electrolyte level within range; refill with distilled water if low.

- Electrolyte Preparation: Adjust sodium carbonate solution concentration (typically 0.7–1.2%) based on load and motor parameters.

- Protection Verification: Test overtemperature, low liquid level, and over-time protections.

- Drive Mechanism Inspection: Ensure smooth operation, no jamming.

With its advanced technology, reliable performance, and smooth start capability, the Liquid Resistance Starter Cabinet is the ideal solution for medium and large industrial motors. It ensures safe, efficient, and long-lasting motor start-up, making it an essential choice for industries seeking reliable power and production stability.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206