Excerpt:

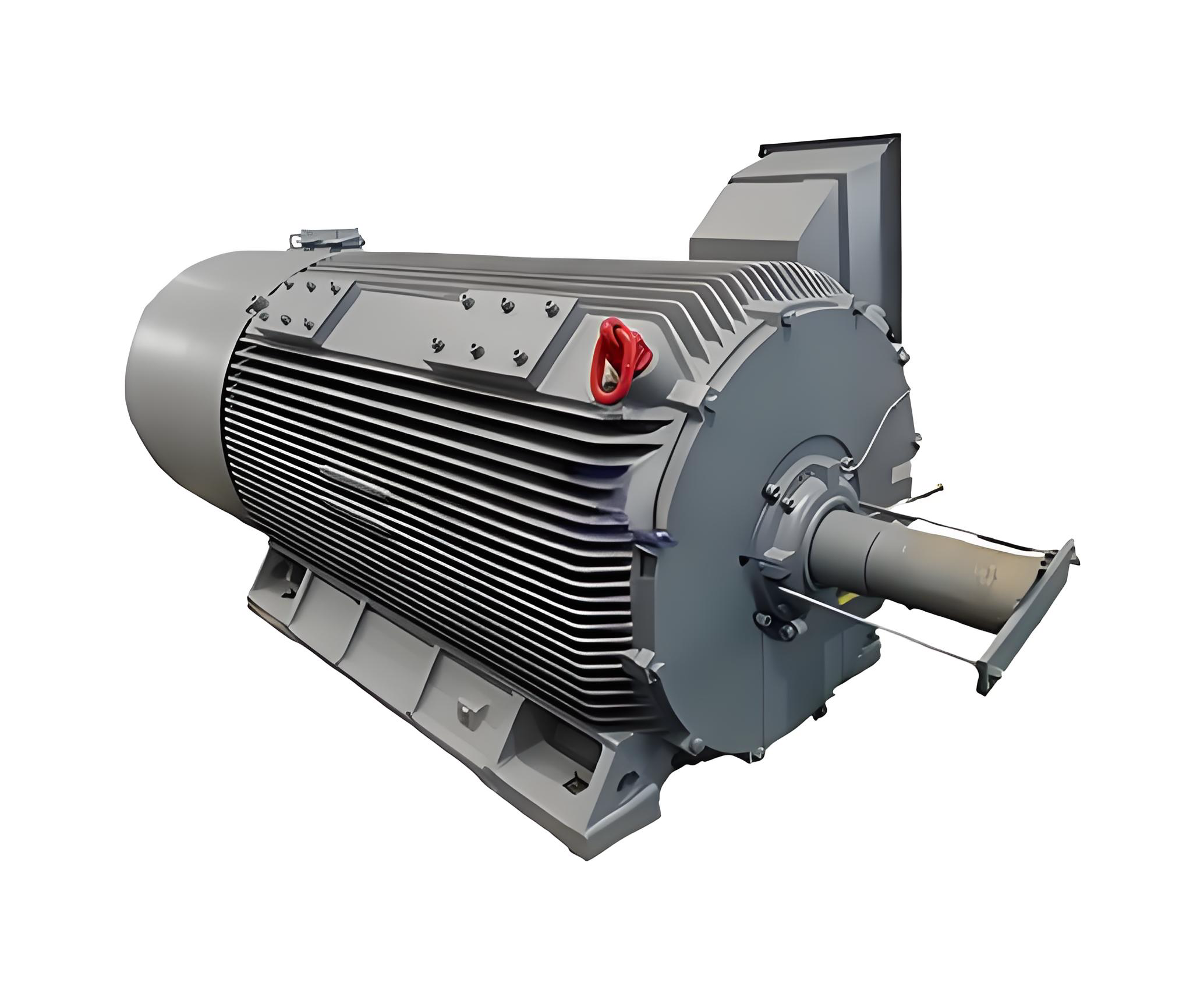

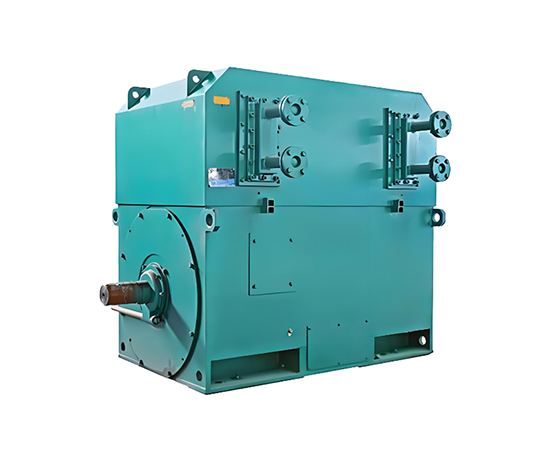

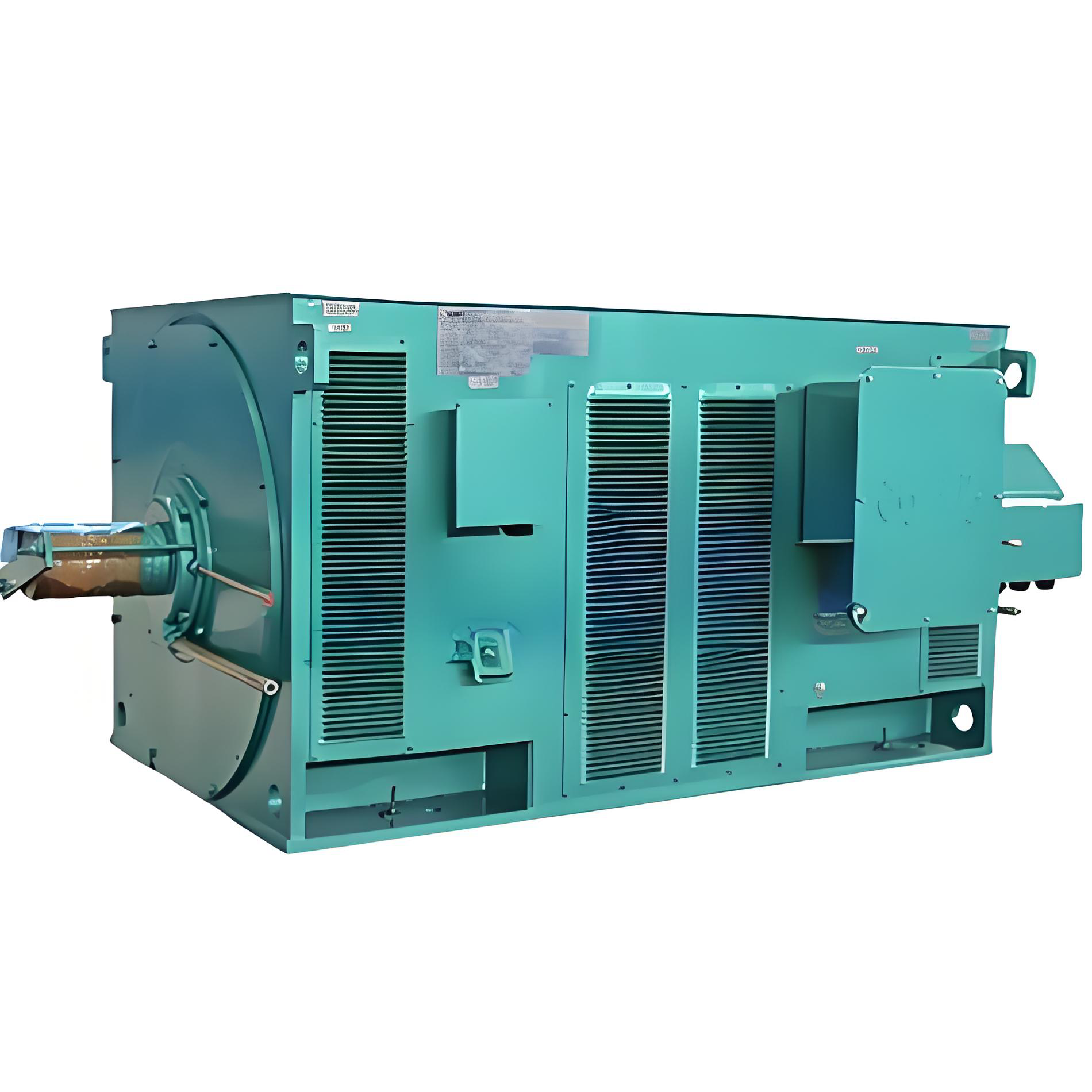

The TYCKK series high-efficiency high voltage permanent magnet synchronous motor is designed for industrial applications requiring high performance, energy efficiency, and precise control. With advanced permanent magnet technology, it delivers superior torque, reliability, and long service life, making it ideal for power plants, heavy machinery, and industrial automation systems.

TYCKK Series High-Efficiency High-Voltage Permanent Magnet Synchronous Motor: The Perfect Combination of Outstanding Energy Efficiency and Reliable Operation

In the field of industrial power transmission, the TYCKK Series High-Efficiency High-Voltage Permanent Magnet Synchronous Motor has become a preferred solution for energy-saving retrofits and power system upgrades, thanks to its exceptional efficiency performance and highly reliable operation.

The TYCKK series high-efficiency high-voltage permanent magnet synchronous motor is an advanced energy-saving drive solution developed by Xima Motor based on many years of design and manufacturing experience. By adopting cutting-edge permanent magnet technology and precision manufacturing processes, this motor series delivers high efficiency, high power factor, remarkable energy-saving performance, stable operation, and long service life. The TYCKK series is strictly manufactured in accordance with JB/T 12681-2016 “Technical Conditions for TYCKK Series (IP44) High-Efficiency High-Voltage Permanent Magnet Synchronous Motors”, providing industrial users with a dependable and mature high-voltage PMSM solution.

1. Product Overview and Technical Features

1.1 Product Introduction

The TYCKK series high-efficiency high-voltage permanent magnet synchronous motor is a new-generation motor developed by Xima Motor to meet modern industry’s dual requirements for energy efficiency and operational reliability. Featuring permanent magnet synchronous technology, this series offers excellent electrical performance, low noise, durability, and ease of maintenance.

With a standard IP44 protection rating, the TYCKK series is suitable for general self-starting applications. Various derivative models based on this series can also follow the same technical principles, highlighting its strong versatility and scalability.

1.2 Core Technical Advantages

- Outstanding energy efficiency: Permanent magnet rotor design significantly improves motor efficiency. Compared with traditional high-voltage induction motors, the TYCKK series offers a wider economic operating range and substantial energy savings.

- Excellent electrical performance: High power factor, low temperature rise, and safe, stable operation improve overall power grid quality and maximize the utilization of existing electrical capacity.

- Robust mechanical structure: Optimized structural design ensures low vibration, long service life, easy installation, and convenient maintenance, even under demanding industrial conditions.

2. Technical Parameters and Performance

The TYCKK series high-efficiency high-voltage permanent magnet synchronous motor covers a wide range of specifications to meet diverse industrial power requirements.

Main Technical Parameters

- Protection class: IP44 (standard)

- Insulation class: F

- Duty type: S1 (continuous duty)

- Efficiency level: High efficiency

- Cooling method: IC series

Performance Highlights

- Wide high-efficiency operating range, maintaining excellent efficiency and power factor across varying loads

- High power factor, reducing reactive power losses and improving grid efficiency

- Low vibration and low noise, achieved through precise dynamic balancing and optimized structural design

3. Structural Design and Configuration

3.1 Main Motor Structure

The TYCKK series adopts an advanced design concept, with each component carefully optimized:

- Permanent magnet rotor: The air-gap magnetic field is generated by rare-earth permanent magnets mounted on the rotor, providing excellent magnetic performance and higher power density.

- Stator structure: F-class insulated stator windings ensure reliable insulation performance and long operating life.

- Protection design: IP44 enclosure effectively prevents dust, moisture, and contaminants from entering the motor.

3.2 Optional Configurations

To meet specific application requirements, the TYCKK series offers flexible options:

- Multiple cooling methods for different operating environments

- Optional protection levels beyond IP44

- Various mounting arrangements to suit different equipment designs

4. Applications and Industries

Thanks to its high efficiency and reliable performance, the TYCKK series high-voltage permanent magnet synchronous motor is widely used across many industrial sectors.

4.1 Heavy Industry Applications

- Power and energy industry: Auxiliary equipment in power plants, pump systems

- Petrochemical industry: Compressors and pumps for continuous, stable operation

- Mining and metallurgy: Crushers, coal mills, hoists, and other heavy-duty equipment

4.2 General Industrial Applications

- Fans and blowers: Industrial ventilation and air handling systems

- Pump systems: Water supply, drainage, and circulating pump applications

- Conveying equipment: Belt conveyors and material handling systems

4.3 Special Operating Environments

Customized solutions are available for:

- High-humidity environments

- Dust-intensive working conditions

- High-temperature applications with optimized cooling systems

5. Product Advantages and Value

5.1 Energy-Saving Benefits

- Significantly reduced energy consumption and operating costs

- Improved power factor, lowering investment in reactive power compensation equipment

- Lower total lifecycle cost despite a slightly higher initial investment

5.2 Operational Reliability

- Strong mechanical structure capable of withstanding thermal and mechanical stresses

- Simple and reliable permanent magnet rotor without rotor bars or slip rings

- Strict quality control throughout production, ensuring compliance with JB/T 12681-2016

5.3 Easy Maintenance

- Modular design reduces maintenance complexity and spare parts inventory

- Maintenance-friendly structure for routine inspection and servicing

- Long service life with extended maintenance intervals

6. Installation and Operation Guidelines

- Suitable for standard industrial environments such as power generation, cement, mining, metallurgy, and chemical industries

- Customized designs available for special operating conditions

- Requires a solid, level foundation and precise alignment when coupled with driven equipment

- Electrical connections must follow the motor nameplate and wiring diagram, ensuring reliable grounding

7. Service and Technical Support

7.1 Quality Assurance

Xima Motor has established a comprehensive quality assurance system for the TYCKK series:

- Full compliance with JB/T 12681-2016

- Strict inspection and testing during manufacturing

- Each motor undergoes no-load, load, and dielectric strength testing before delivery

7.2 After-Sales Service

- Fast response to customer feedback and service requests

- On-site technical support until issues are fully resolved

- Long-term technical support and service commitment

With its advanced permanent magnet technology, outstanding energy efficiency, and stable, reliable operation, the TYCKK Series High-Efficiency High-Voltage Permanent Magnet Synchronous Motor has become a leading solution in modern industrial power systems. Through continuous innovation and rigorous quality control, Xima Motor ensures that every TYCKK motor delivers efficient, stable, and sustainable power even in demanding industrial environments.

Choosing the Xima TYCKK series means choosing high efficiency, reliability, and professional technical support for your industrial applications.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206