Excerpt:

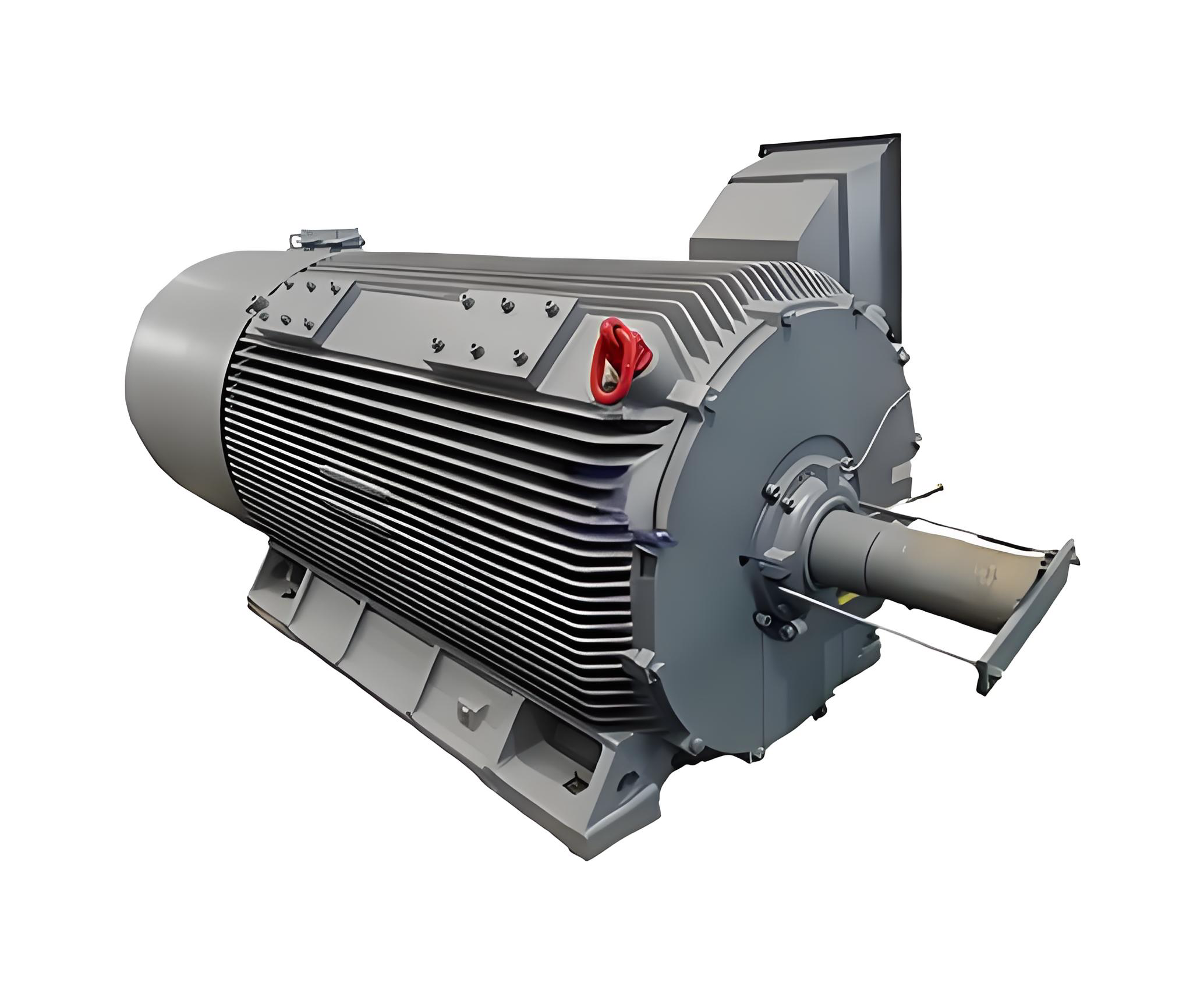

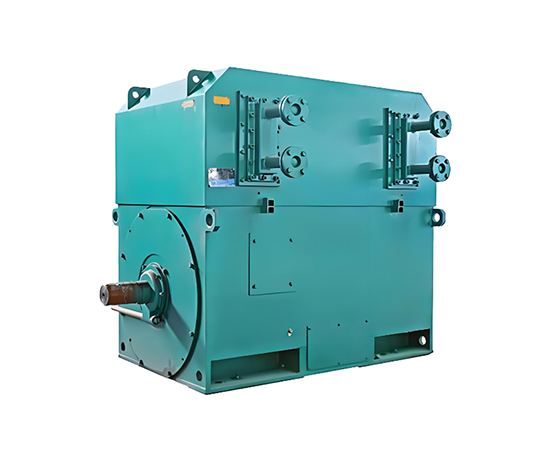

The TYE4 series low voltage high-efficiency permanent magnet synchronous motor is designed for industrial applications requiring precise control, high energy efficiency, and reliable performance. Utilizing advanced permanent magnet technology, it provides stable operation, superior torque, and long service life for automation systems, machinery, and equipment.

TYE4 Series Low-Voltage High-Efficiency Permanent Magnet Synchronous Motor: Perfect Combination of Superior Energy Efficiency and Stable Operation

TYE4 Series Low-Voltage High-Efficiency Permanent Magnet Synchronous Motor: Optimal Energy Efficiency and Reliable Performance

The TYE4 Series Low-Voltage High-Efficiency Permanent Magnet Synchronous Motor by SIMO Motor is engineered for industrial power applications requiring high energy efficiency, stable operation, and long-term reliability. Ideal for industrial energy-saving retrofits and performance upgrades, this series integrates advanced permanent magnet technology, precision manufacturing, and modular design to deliver superior efficiency, extended service life, and minimal maintenance.

Compliant with JB/T 13297-2017 "Technical Conditions for TYE4 Series Three-Phase Permanent Magnet Synchronous Motors (Frame H80–H355)", the TYE4 series provides a reliable, high-performance solution for a wide range of industrial low-voltage applications.

I. Product Overview and Key Features

1. Product Introduction

The TYE4 Series covers frame sizes H80–H355 with power ratings ranging from 0.55kW to 375kW, supporting diverse industrial applications. It is designed as an advanced upgrade over traditional asynchronous motors, offering low noise, low vibration, excellent electrical parameters, and high durability.

The series supports multiple cooling methods (IC411, IC416) and protection levels (IP54, IP55), ensuring adaptability to complex operational environments and providing compatibility with various industrial installation standards.

2. Core Technical Advantages

- High-Efficiency Performance: Permanent magnet rotor ensures high efficiency over a wide load range (25%-120%), delivering significant energy savings.

- Superior Operational Stability: Low noise, low vibration, low temperature rise, and constant torque across a wide speed range.

- Industrial Compatibility: Installation dimensions match YE2, YX3, YE3, YE4 series motors for easy replacement.

- Robust Construction: Mechanical design optimized for high reliability under continuous industrial operation.

II. Technical Parameters and Performance Indicators

Main Specifications

| Parameter Category | Specifications & Performance Indicators |

|---|---|

| Frame Size | H80–H355 |

| Rated Power | 0.55kW–375kW |

| Rated Voltage | 380V |

| Rated Frequency | 50Hz |

| Pole Range | Multiple pole configurations available |

| Protection Class | IP54, IP55 (customizable) |

| Insulation Class | F-Class |

| Cooling Method | IC411 / IC416 (≥55kW, 3000rpm) |

| Duty Cycle | S1 (Continuous Duty) |

| Energy Efficiency | GB30253-2013 Level 1 |

| Mounting Type | IMB3, IMB35 standard options |

Performance Highlights

- Wide Efficient Operating Range: Maintains high efficiency across 25%-120% load.

- High Power Factor: Permanent magnet synchronous design minimizes reactive power, enhancing grid efficiency.

- Advanced Starting Capability: Cage-type starting rotor enables high starting torque without requiring a variable frequency drive.

III. Structural Design and Configuration

1. Motor Main Structure

- Rotor: High-performance permanent magnets eliminate excitation current, with cage-type starting windings for asynchronous start capability.

- Stator: F-class insulation for long-lasting performance, optimized for compatibility with conventional asynchronous motors.

- Cooling System: Self-cooling (IC411) or forced cooling (IC416), maintaining optimal temperature across varying loads.

2. Optional Features

- Cooling Flexibility: IC411 or IC416 depending on application requirements.

- Protection Class Options: IP54, IP55, adaptable for harsh industrial environments.

- Mounting Versatility: Supports IMB3, IMB35, and other configurations.

IV. Industrial Applications

1. General Industrial Applications

- Fans: High-efficiency ventilation and blower systems.

- Pumps: Industrial water circulation, wastewater, and process pumping systems.

- Material Handling: Belt conveyors, transfer equipment, and processing lines.

2. Manufacturing & Processing

- Machine Tools: Main spindle drives with precise and stable power output.

- Light Industry: Packaging, food processing, and assembly machinery.

3. Specialized Applications

- Wide Speed Range Operations: Compatible with variable frequency drives for energy-efficient speed regulation.

- High Starting Torque Requirements: Excellent starting performance for heavy-duty equipment.

- Heavy-Duty Drives: Motors designed for industrial mixers, extruders, and high-load processing systems.

V. Advantages and Value Proposition

1. Energy Efficiency

- Reduces operational costs by maintaining high efficiency across 25%-120% load.

- High power factor reduces reactive power compensation needs.

- Optimized lifecycle costs with significant energy savings over time.

2. Reliability

- Robust mechanical design withstands industrial stress.

- Simple rotor construction: no bars or slip rings, minimizing maintenance requirements.

- Quality-controlled production ensures compliance with industry standards.

3. Maintenance Convenience

- Standardized frame for easy replacement and compatibility.

- Modular design reduces spare part inventory and service complexity.

- F-class insulation ensures long service life and extended maintenance intervals.

VI. Installation and Operation Guidelines

- Suitable for standard industrial environments, indoor or outdoor, non-hazardous atmospheres.

- Solid, level foundation required.

- Precision alignment required for coupling with driven equipment.

- Electrical connections must follow wiring diagrams, ensuring grounding compliance.

VII. Service and Technical Support

- Compliant with JB/T 13297-2017 standards.

- Comprehensive factory testing, including no-load, full-load, and insulation withstand tests.

- On-site support within 48 hours for troubleshooting or maintenance.

- Long-term technical assistance ensures optimal performance throughout the product lifecycle.

The TYE4 Series Low-Voltage High-Efficiency Permanent Magnet Synchronous Motor from SIMO Motor delivers unmatched energy efficiency, operational reliability, and long-term durability, making it the ideal choice for modern industrial power systems.

Selecting the SIMO Motor TYE4 Series guarantees stable, high-efficiency performance with professional technical support, optimized for industrial energy savings and long-term operational success.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206