Excerpt:

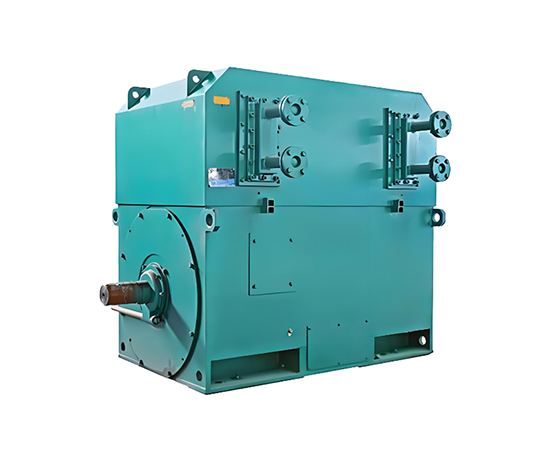

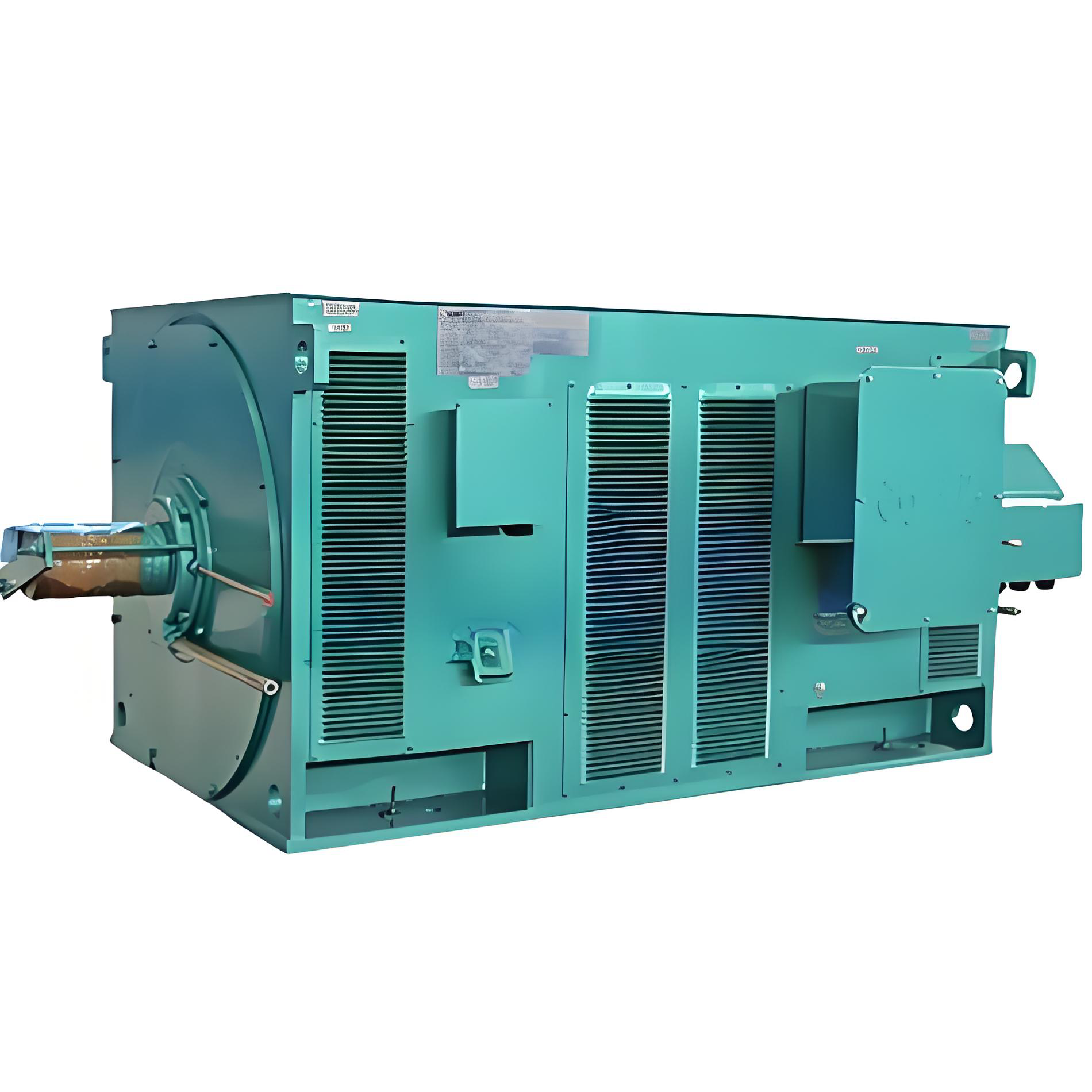

The YX series high-efficiency high voltage three-phase asynchronous motor is designed for industrial applications requiring reliable performance, high efficiency, and durability. Suitable for power plants, mining, heavy machinery, and other large-scale industrial systems, it delivers consistent energy-efficient operation.

YX Series High-Efficiency High-Voltage Three-Phase Asynchronous Motor: Exceptional Energy Efficiency and Reliable Industrial Power Solution

In industrial power applications, the YX Series High-Efficiency High-Voltage Three-Phase Asynchronous Motor from SIMO Motor delivers superior energy efficiency and reliable operation, making it the preferred choice for industrial energy-saving upgrades and power system enhancements.

Developed based on years of design and manufacturing expertise, the YX Series integrates advanced electromagnetic optimization and precision engineering, providing high efficiency, significant energy savings, reliable performance, and long service life. The series fully complies with T/STIC C110040-2021 "YX Series High-Efficiency High-Voltage Three-Phase Asynchronous Motors (Frame Sizes 355~630)", offering dependable high-voltage motor solutions for diverse industrial applications.

I. Product Overview and Key Features

1. Product Introduction

The YX Series encompasses 728 specifications with pole counts ranging from 2P to 12P, rated voltages of 6kV and 10kV, and power outputs from 185kW to 4000kW (select models up to 13200kW), meeting the full spectrum of industrial power demands.

As an upgraded Y-series motor, the YX Series features modular design, excellent electrical parameters, low noise, durability, and ease of maintenance. Cooling options include air-to-air (YX), air-to-water (YXKK), and open-type (YXKS), adaptable to various complex operating environments.

2. Core Technical Advantages

- Outstanding Energy Efficiency: Optimized electromagnetic design and low-loss materials ensure all models achieve Level 1 energy efficiency, delivering substantial energy savings.

- Superior Electrical Performance: F-class insulation and VPI vacuum pressure impregnation provide excellent insulation reliability and long service life. Stator windings use dual-layer formed coils with mica and glass tape for enhanced electrical durability.

- Robust Mechanical Design: Full steel welded frame optimized via finite element analysis; rotors use cage-type construction with induction-heated welding and rotor bar expansion processes to maintain low vibration over long-term operation.

II. Technical Parameters and Performance Indicators

| Parameter Category | Specifications & Performance Indicators |

|---|---|

| Frame Size | H355–H630 (expandable to H710) |

| Rated Power | 185kW–4000kW (select models up to 3150kW or 13200kW) |

| Rated Voltage | 6kV, 10kV (customizable) |

| Pole Count | 2P–12P |

| Protection Class | IP23, IP44, IP54, IP55 (depending on cooling method) |

| Insulation Class | F-Class, H-Class |

| Cooling Method | IC01, IC611, IC81W (depending on model) |

| Mounting Type | IMB3, IMB35 (depending on model) |

Performance Highlights

- High Efficiency Across Load Range: Maintains optimal efficiency under varying loads, reducing energy consumption.

- High Starting Torque: Special rotor design provides excellent startup performance for fans, pumps, and compressors.

- Wide Voltage Adaptability: Stable performance under fluctuating grid conditions.

- Low Vibration & Noise: Precision dynamic balancing and optimized structure ensure smooth operation and quiet performance.

III. Structural Design and Configuration

1. Main Motor Structure

- Frame: High-quality steel welded frame optimized through finite element analysis for strength, light weight, and aesthetics.

- Stator: Low-loss silicon steel laminations, dual-layer formed coils, VPI treatment, and silver-copper brazed connections for high insulation reliability and moisture resistance.

- Rotor: Cage-type rotor with induction-heated welding and bar expansion; rotor shafts selected according to environmental requirements; copper or copper alloy bars based on load and customer needs.

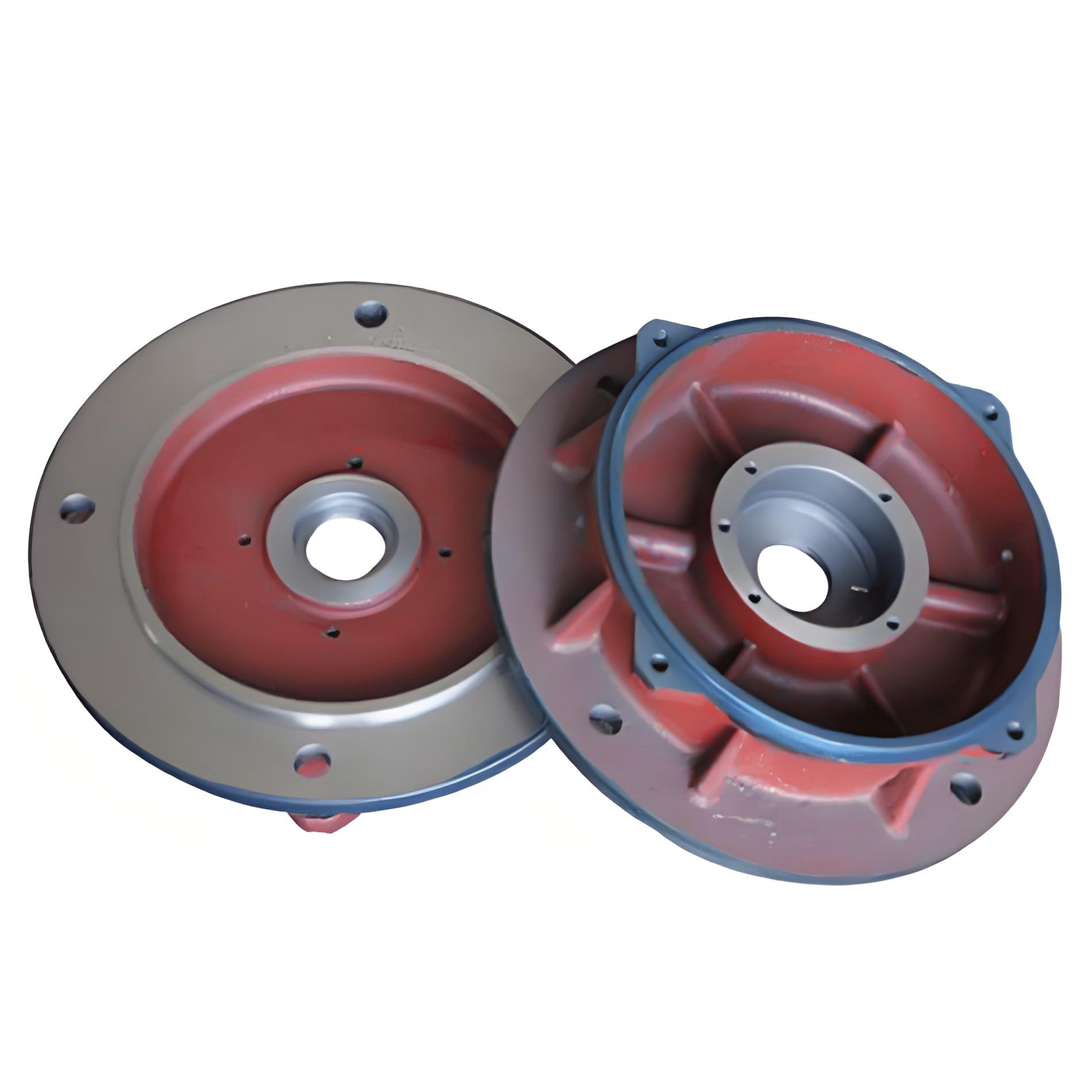

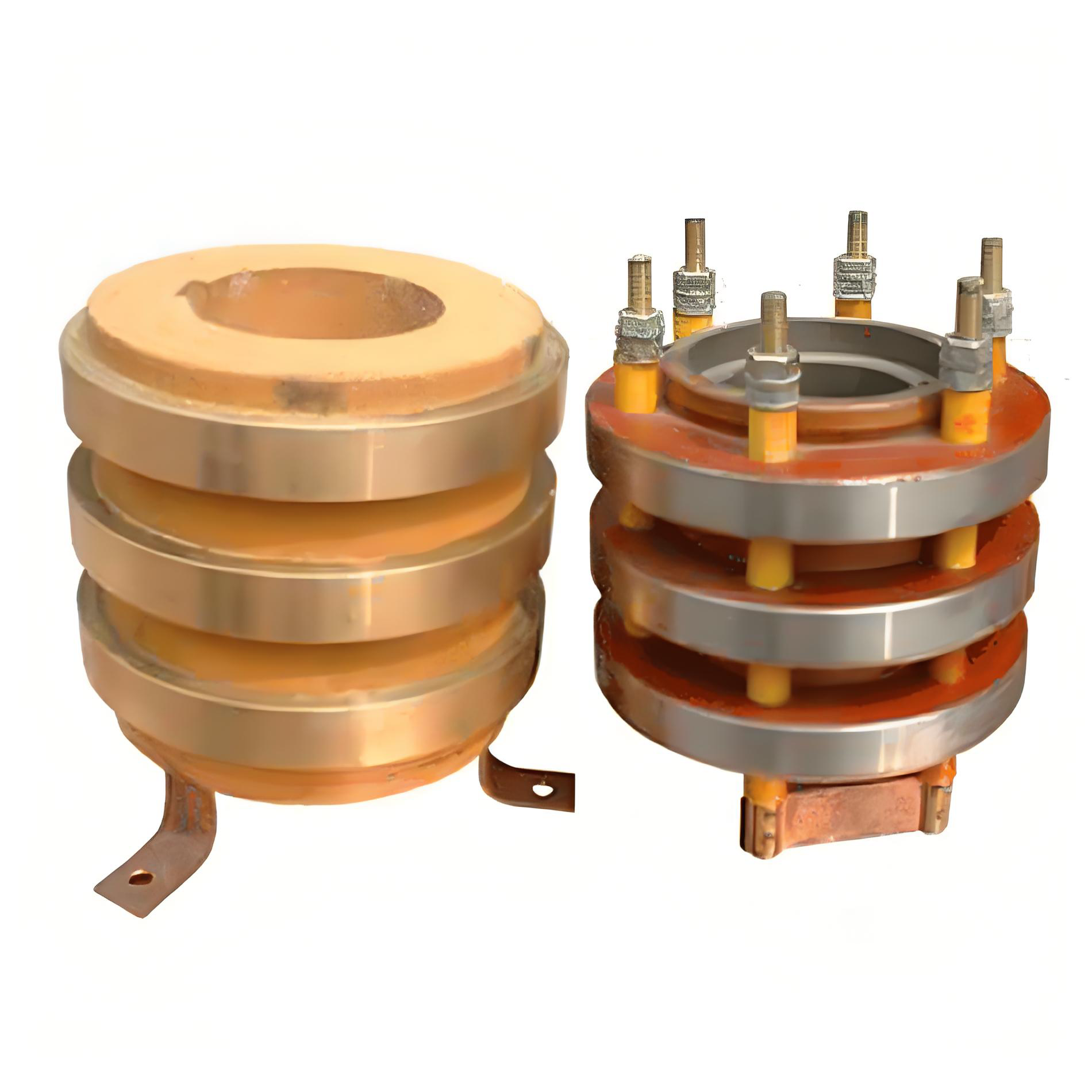

2. Bearings and Lubrication

- Rolling Bearings: Fixed drive-side (D) and floating non-drive side (ND) with preloaded dual ball bearings; re-lubrication without shutdown.

- Sleeve Bearings: Flanged and bolted design, typically floating to avoid axial load; standard IP55 protection.

3. Cooling System

- Air-to-Air (IC611): Suitable for relatively clean environments.

- Air-to-Water (IC81W): Fully enclosed structure with air-water heat exchanger and internal axial fans; dustproof housing.

- Open-Type (IC01): Suitable for indoor environments with controlled conditions.

IV. Industrial Applications

1. Heavy Industry

- Petrochemical: Compressors, pumps for continuous operation.

- Power Generation: Auxiliary systems, water pumps.

- Mining & Metallurgy: Crushers, coal mills, hoists, rolling mills under harsh conditions.

2. General Industry

- Fans & Blowers: Efficient ventilation and air movement.

- Pumps: Industrial water and circulation systems.

- Material Handling: Conveyors, belt systems, and transfer machinery.

3. Specialized Environments

- High Humidity: Customized insulation and protective coatings.

- Dusty Locations: Fully enclosed cooling prevents dust ingress.

- High Temperature: Optimized cooling for stable operation in elevated temperatures.

V. Advantages and Value

1. Energy Efficiency

- Reduces operational costs with high efficiency.

- Optimizes power factor, lowering reactive power investments.

- Low total lifecycle cost despite higher initial investment due to energy savings.

2. Reliability

- Optimized mechanical structure withstands mechanical and thermal stresses.

- High-quality materials resist wear and corrosion.

- Strict quality control ensures compliance with standards.

3. Maintenance Convenience

- Modular components reduce maintenance complexity and spare parts inventory.

- Easy access for inspection and repairs.

- Optional temperature monitoring for stator windings and bearings.

VI. Installation and Operation Guidelines

- Suitable for altitudes ≤1000m, ambient temperature -15°C to +40°C.

- Indoor or outdoor, non-hazardous environments.

- Solid, level foundation required.

- Accurate alignment with driven equipment; follow wiring diagrams and grounding requirements.

VII. Service and Technical Support

- ISO9001 certified quality management system; CE and CCC certification for select products.

- Comprehensive factory testing: no-load, full-load, and insulation withstand tests.

- Rapid response: 24-hour reply, 48-hour on-site support for service calls.

- Lifetime technical support and warranty.

The YX Series High-Efficiency High-Voltage Three-Phase Asynchronous Motor from SIMO Motor delivers high performance, robust construction, and reliable operation, making it the preferred choice for industrial power applications.

Choosing SIMO Motor YX Series ensures reliable equipment performance, energy efficiency, and professional technical support for industrial operations.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206