Excerpt:

The SIMO ZDT2 series DC motor is designed for high-performance applications that require reliable and efficient DC power. Offering excellent control, durability, and energy efficiency, it is ideal for use in a wide range of industrial machinery, including conveyors, pumps, and other automation systems.

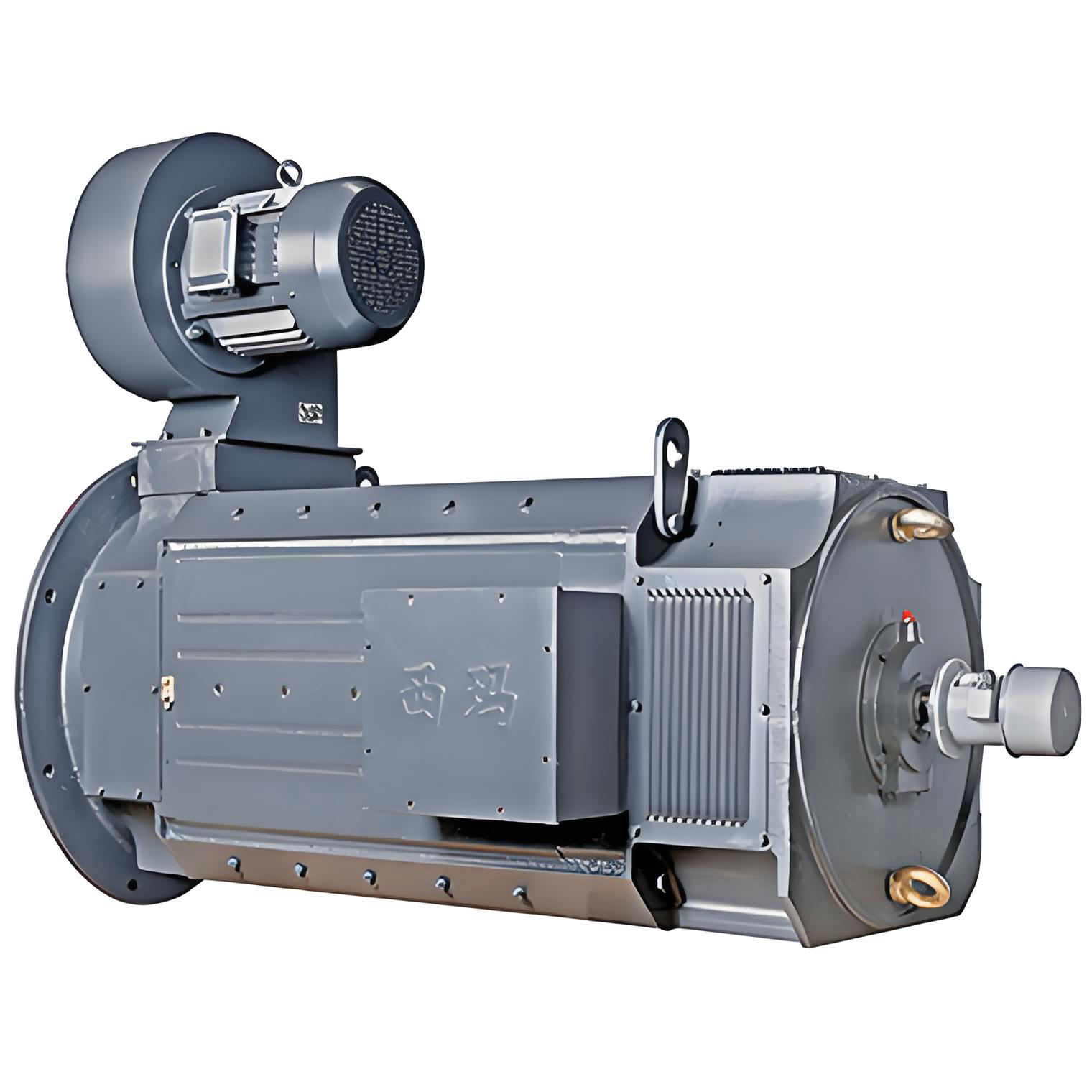

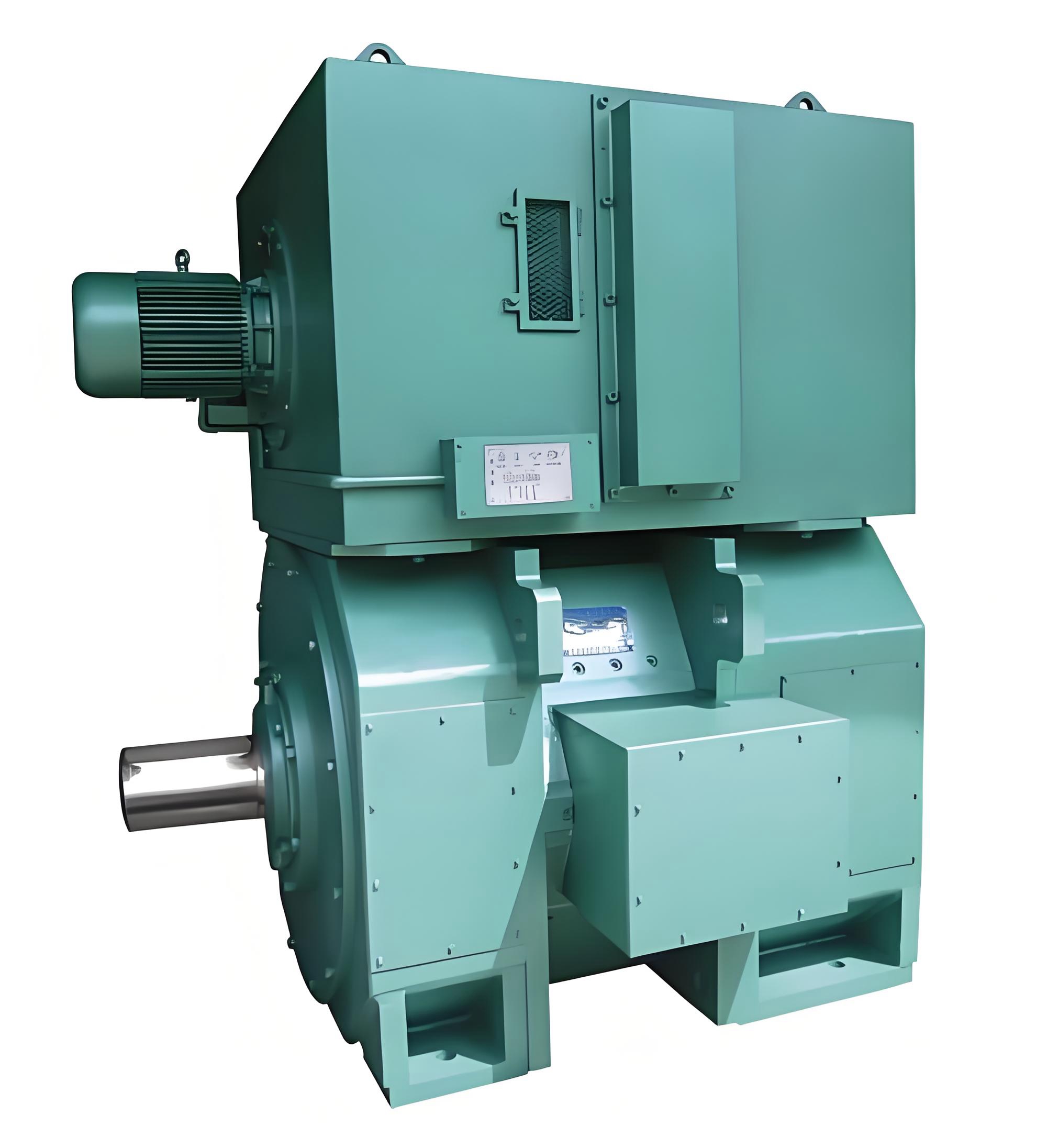

Xi’an Simo Motor ZDT2 Series DC Motors – Sugar Mill Roller Press Dedicated Drive Solution

1. Product Overview – High-Efficiency Drive for Sugar Industry

The ZDT2 series DC motors are specifically designed for sugar mill roller presses, leveraging the advanced medium-sized DC motor platform. They combine innovative electromagnetic design and optimized structural engineering, offering:

- High overload capacity for heavy-start applications

- Stable and precise speed control during operation

- Reliability in continuous and harsh industrial environments

This makes the ZDT2 series the ideal choice for sugar industry roller press drive systems.

2. Product Positioning & Technical Standards

Professional Product Positioning

- Developed on the mature Z-series medium-sized DC motor platform

- Optimized for roller press drives in sugar production

- Addresses industry-specific demands: heavy load, continuous operation, and harsh environment

Standards Compliance

- National standards (GB) and IEC international standards

- ISO-standardized mechanical dimensions and tolerances ensure global compatibility and interchangeability

3. Operating Environment & Technical Conditions

Environmental Adaptability

- Designed for harsh industrial conditions

- Cooling method and protection level must be selected according to site conditions to maintain motor cleanliness and performance

Key Operating Conditions

- Air quality: free from acidic or alkaline gases that could affect insulation or commutation

- Climate: suitable for humid tropical environments, max ambient temperature ≤ 40°C

- Power supply: supports static rectifier power supply, compatible with conventional DC generator supply

- Rectifier requirements: minimum 6-pulse rectifier; ripple factor ≤ 10% at rated speed, voltage, and current without additional smoothing reactor

4. Structural Design & Installation Features

Protection & Cooling Systems

- Protection ratings: IP23 / IP44 per GB/T4942.1 & IEC34-5

- Cooling options (GB/T1993 & IEC34-6):

- IC06: self-ventilated with built-in fan

- IC17: ducted inlet with louvered exhaust

- IC37: ducted inlet and outlet for optimal airflow

- Cooling air enters from the drive end to ensure effective heat dissipation

Flexible Installation

- Installation standards: GB997 & IEC34-7

- Mounting options:

- IM1001: end-bearing, foot-mounted, single shaft

- IM1002: end-bearing, foot-mounted, double shaft

- Outlet box: standard right-side (can customize reverse box)

- Shaft direction: standard single shaft, left output facing box

- Rotation: viewed from commutator end, counterclockwise

- Recommended coupling: flexible coupling

5. Performance Features

Core Parameters

- Duty cycle: S1 continuous operation

- Voltage: standard 440V / 520V, customizable

- Excitation: separately excited (he励), 4-terminal windings (two series pairs, 220V total), custom voltages available

Overload Capability

- Base speed: 2.5× rated current short-term overload

- High speed: 1.8× rated current

- Dynamic response: di/dt up to 200× rated current/sec

Optional Functional Accessories

- Tachogenerator: accurate speed feedback

- Pulse generator: precise position control

- Centrifugal switch: speed protection

- Braking system: fast stop functionality

Note: Technical parameters may be updated with new materials or technology; always refer to the latest datasheets.

6. Quality Assurance – Simo Motor System

Enterprise Capabilities

- Integrated DC motor design and manufacturing chain

- Mechanical processing, mold design, and casting processes

- Dedicated solutions for sugar industry drive systems

Certifications & Honors

- Management systems: ISO9001, ISO14000, OHSAS18000

- Product certifications: CE, UL, CCC

- Recognized as Top 500 Mechanical Industry / Top 100 Electrical Industry company

- Quality awards: AAA credit rating, "National & City Brand Products"

Quality Commitment

- Standardized manufacturing: strict adherence to national and international standards

- 72-hour continuous operation testing

- Timely delivery and flexible scheduling for special orders

- Rapid technical support: 24h response, 48h onsite service

- Three-package service & lifetime cost warranty

7. Selection & Ordering Guide

Standard Ordering Process

- Refer to the ZDT2 product catalog to select the correct model

- Confirm parameters in contract:

- Complete motor model

- Rated power & voltage

- Rotation speed

- Excitation type & voltage

- Installation type

Example:ZDT2-450-3 500kW 440V 650r/min He励 220V, horizontal with feet / IMB3

Special Requirements

- Structural changes: double shaft, reverse box, reverse rotation

- Non-standard specifications: custom contracts for beyond catalog ranges

- Accessories: brushes, brush holders, spare parts to be specified in order

8. Sugar Industry Advantages

- Heavy-load startup: meets roller press demand

- Stable speed control: ensures consistent juice extraction

- High overload capacity: handles transient peak loads

- Harsh environment adaptation: protection against dust, heat, and humidity

Reliability & Economy:

- Optimized electromagnetic design + innovative cooling

- Balanced high performance, long-term reliability, and operating cost efficiency

Conclusion

The ZDT2 series DC motor is the preferred choice for sugar mill roller press drive systems, providing reliable, high-performance, and custom-tailored drive solutions.

Contact Simo Motor technical team for detailed specifications or personalized selection guidance.

If you want, I can also create a full comparison table of Z2, Z4, ZSN4, ZDB, and ZDT2 series motors, showing power ranges, applications, and special features, which is excellent for your product catalog or sales guide. Do you want me to do that next?

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206