Excerpt:

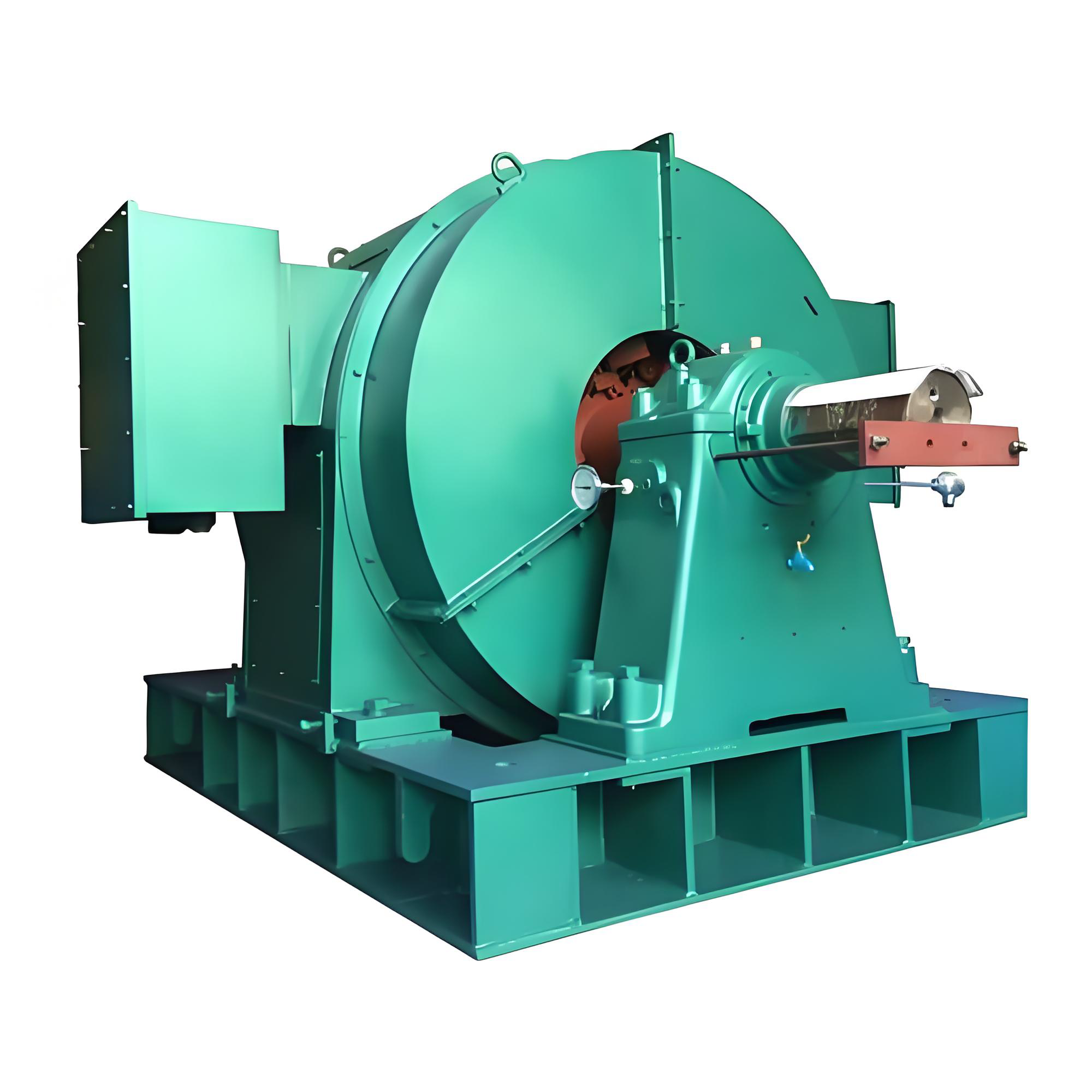

The SIMO Z2 series DC motor is designed for industrial applications where high efficiency and reliable performance are essential. This motor delivers exceptional speed control and durability, making it ideal for use in systems like conveyors, lifting equipment, and electric drives.

Xi’an Taifu Simo Motor Z2 Series DC Motor – Professional Selection Guide

Classic DC Drive Solution for Diverse Industrial Transmission Applications

The Xi’an Taifu Simo Motor Z2 Series DC Motor is a classic second-generation nationally standardized DC motor product. Based on mature DC motor technology and optimized electromagnetic design, this series maintains traditional advantages while delivering stable, reliable operation and wide environmental adaptability. It is an ideal power solution for a broad range of industrial drive applications.

Model Identification – Accurate Recognition of Motor Specifications

The Xi’an Taifu Simo Motor Z2 Series DC motor adopts a standardized designation system. The model structure is explained as follows:

Model Code Definition

- “Z”: DC motor

- “2”: Second national unified design series

- Numbers after the hyphen: Combination of frame size and core length

Typical Examples

- Z2-41:

- “4” indicates frame size No.4

- “1” indicates short core length

- Z2-112:

- “11” indicates frame size No.11

- “2” indicates long core length

This naming system strictly follows JB1104-68, issued by the Ministry of Machinery Industry of the People’s Republic of China, ensuring product standardization and interchangeability.

Technical Overview – Professional Design for Multiple Application Requirements

Series Range and Classification

The Z2 series small DC motors include 11 standard frame sizes, with two core length options for each frame. According to functional requirements, the series includes:

- DC motors

- DC generators

- DC voltage-regulating generators

All are suitable for general industrial operating environments.

Main Technical Characteristics

Excitation Configuration

- Motors: Shunt excitation or separately excited with stabilizing windings

- Generators: Compound excitation or separate excitation (rated voltage 230 V)

- Voltage-regulating generators: Shunt excitation without series field windings

Separate excitation voltage options:

110 V or 220 V. Motors with rated voltage of 110 V are matched only with 110 V excitation voltage.

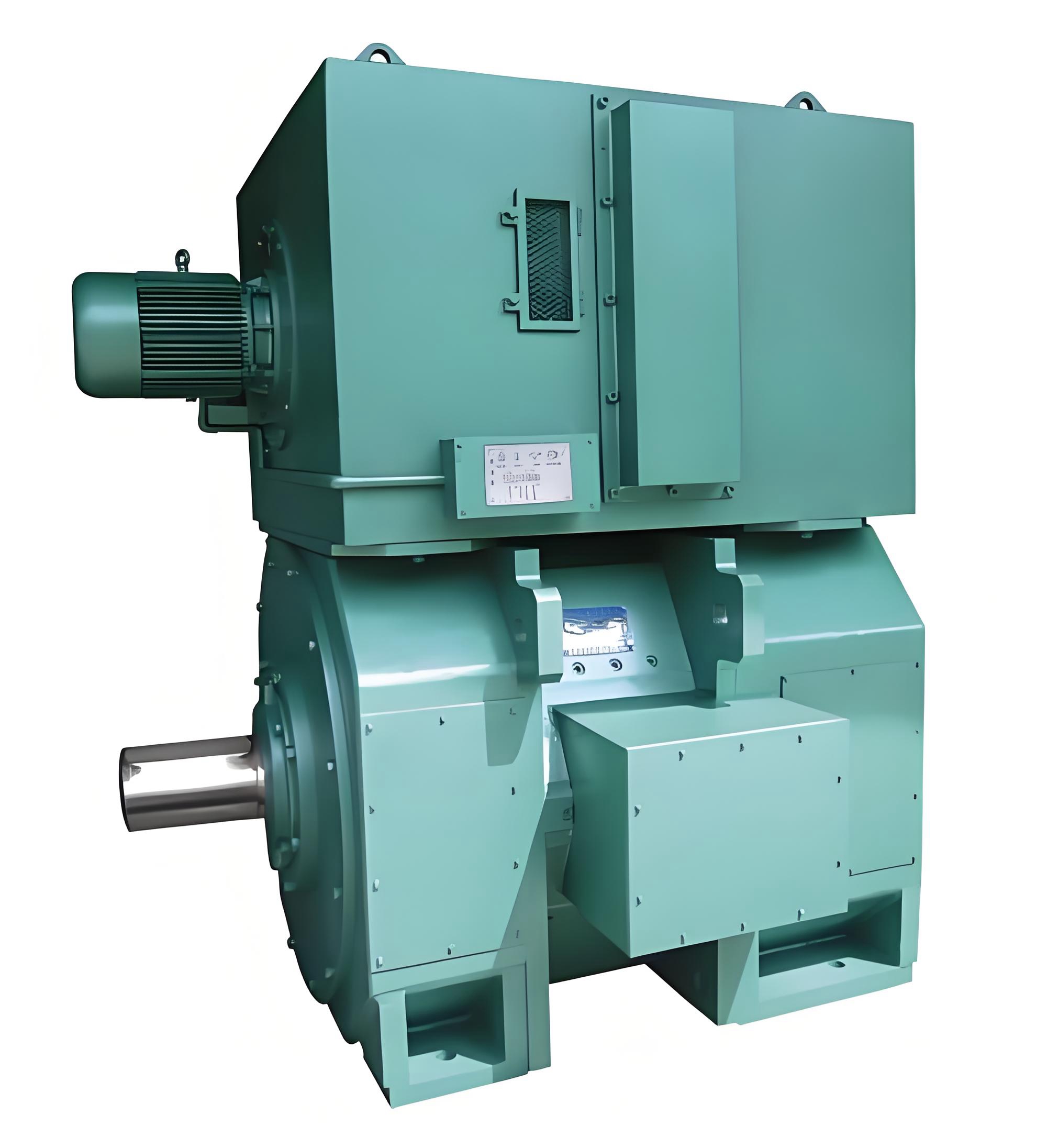

Drive and Installation Features

The motor supports V-belt drive, spur gear drive, or elastic coupling. The specially designed bearing structure ensures that the motor shaft does not bear axial thrust. For special environments, TH tropical DC motors with moisture-proof, mildew-proof, and anti-fume features can be supplied.

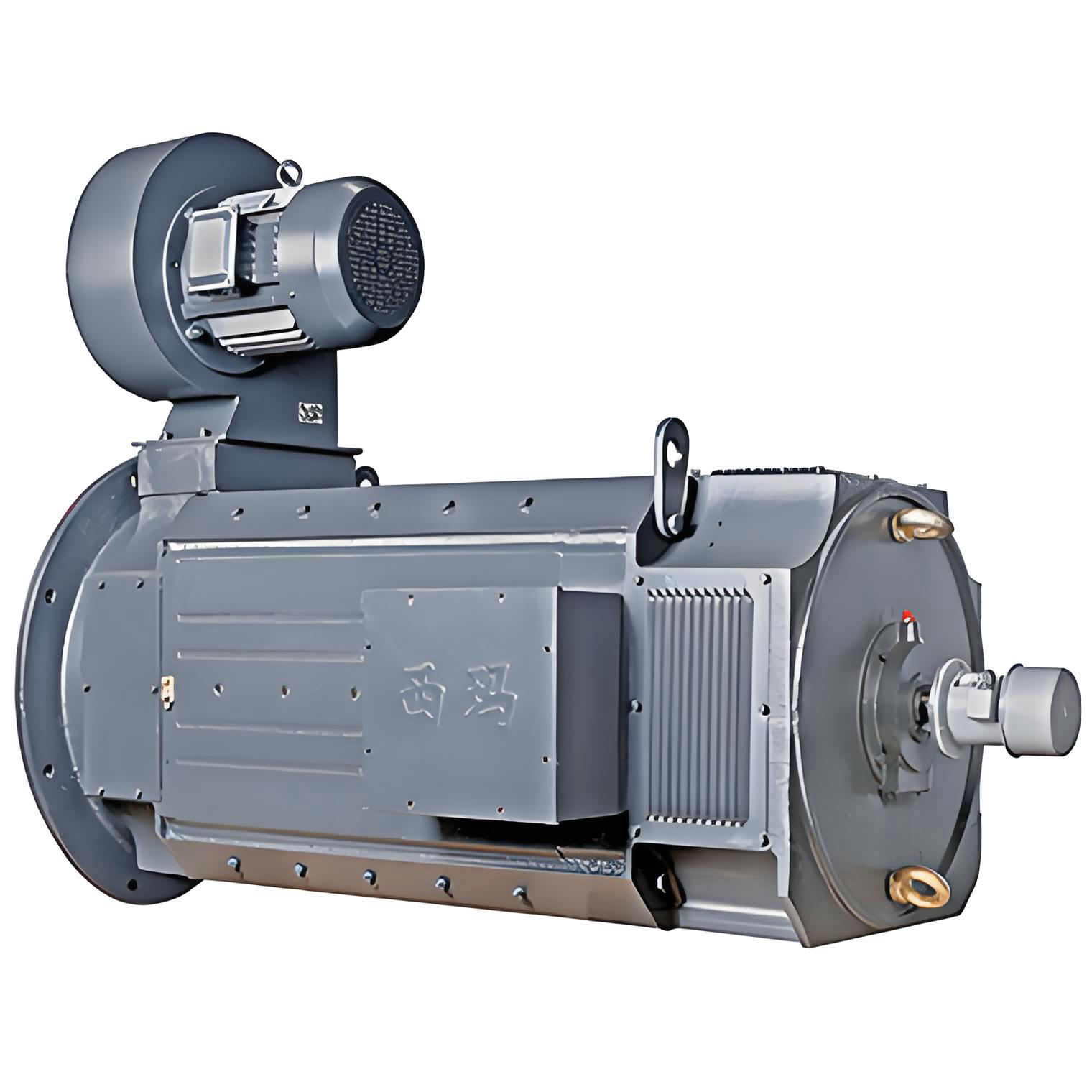

Ventilation and Cooling Design

The standard series uses self-ventilated cooling. When speed is reduced by lowering armature voltage, torque decreases proportionally with speed.

For Z2 frame sizes 6–11, an external forced ventilation option is available. The blower is mounted above the shaft-end end cover to enhance cooling performance.

Core Technical Advantages – Reliable Performance Assurance

Precise Speed Regulation Performance

Z2 series DC motors are suitable for applications with a constant power speed regulation range up to 2:1, with overload capacity not exceeding 1.5 times rated torque. Optimized electromagnetic design ensures stable operation throughout the speed control range.

Wide Application Adaptability

These motors are widely used in:

- Metal cutting machine tools

- Paper-making machinery

- Textile and dyeing equipment

- Printing machinery

- Cement and building material production

DC generators can be used as power sources for lighting, control systems, or constant-voltage power supply applications.

Reliable Insulation System

The motors adopt Class B insulation, processed with special insulation treatment for excellent thermal endurance and electrical performance. Strict manufacturing standards ensure long-term stable operation under rated conditions.

Flexible Structural Variants

Frame sizes 2–11 can be derived into ZYS-A tachogenerator structures, supporting speed feedback and control systems. Multiple mounting arrangements and protection levels provide flexible configuration options.

Comprehensive Quality Assurance System of Simo Motor

Corporate Strength

Simo Motor Group Co., Ltd. is a key enterprise in China’s motor manufacturing industry, specializing in R&D and production of large and medium-sized high- and low-voltage AC and DC motors. The company operates a complete industrial chain integrating motor design, electrical control, machining, mold manufacturing, casting, and logistics, delivering comprehensive power system solutions.

Certifications and Honors

- Quality management system: ISO9001

- Environmental and safety management: ISO14000, OHSAS18000

- International certifications: CE, UL, CCC

- Industry status: China Machinery Industry Top 500, Top 100 Electrical Industry Enterprises

- Quality honors: AAA Credit Enterprise, Provincial and Municipal Famous Brand Products, “China Light of Fame” Brand

Selection Guide and Technical Parameters

Standard Configuration Parameters

| Parameter | Specification |

|---|---|

| Mounting type | Horizontal B3 |

| Insulation class | Class B |

| Protection class | IP44 |

| Excitation method | Shunt / Separate excitation |

| Excitation voltage | 110 V / 220 V |

Important Selection Notes

Drive Method Restrictions

- 2-pole motors ≥ 5.5 kW: belt drive not permitted

- 4-pole motors ≥ 37 kW: belt drive not permitted

- Elastic coupling or spur gear drive is recommended

Environmental Adaptability

- Standard models: general industrial environments

- TH tropical type: humid, mildew-prone environments

- Special environments: consult technical department in advance

Professional Selection Recommendations

Application-Oriented Selection Factors

Motor Selection Considerations

- Load characteristics and required speed regulation range

- Overload capacity and starting torque

- Installation space and ventilation conditions

Generator Selection Considerations

- Output voltage stability and accuracy

- Load type and fluctuation range

- Cooling method and ambient conditions

Handling Special Requirements

For applications with special requirements:

- Communicate detailed needs with technical support in advance

- Provide complete operating environment parameters

- Clearly define performance targets and special functional requirements

Ordering Guide

Standard Ordering Information

When ordering Z2 series DC motors, please specify:

- Motor model and specification code

- Rated power and voltage

- Required speed range

- Excitation method and excitation voltage

- Mounting arrangement and protection class

- Environmental adaptation requirements

Special Ordering Requirements

Please clearly state if any of the following are required:

- Special excitation methods or voltage levels

- Non-standard mounting structures or protection classes

- TH tropical type or special environment versions

- Integrated tachogenerators or other derived structures

- Other customized technical parameters or configurations

Technical Service and Support

Xi’an Taifu Simo Motor provides comprehensive technical services, including:

- Selection guidance by professional engineers

- Technical consultation on operation and parameters

- After-sales support with rapid response

- Customized solutions for special application needs

Conclusion

With mature technology, reliable performance, and wide application adaptability, the Xi’an Taifu Simo Motor Z2 Series DC Motors have become a key choice in industrial DC drive systems. Backed by strong technical expertise and a complete service system, Simo Motor delivers professional support and dependable after-sales service to customers worldwide.

For detailed technical specifications or customized motor selection assistance, please contact the Simo Motor professional technical team for comprehensive support.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206