Excerpt:

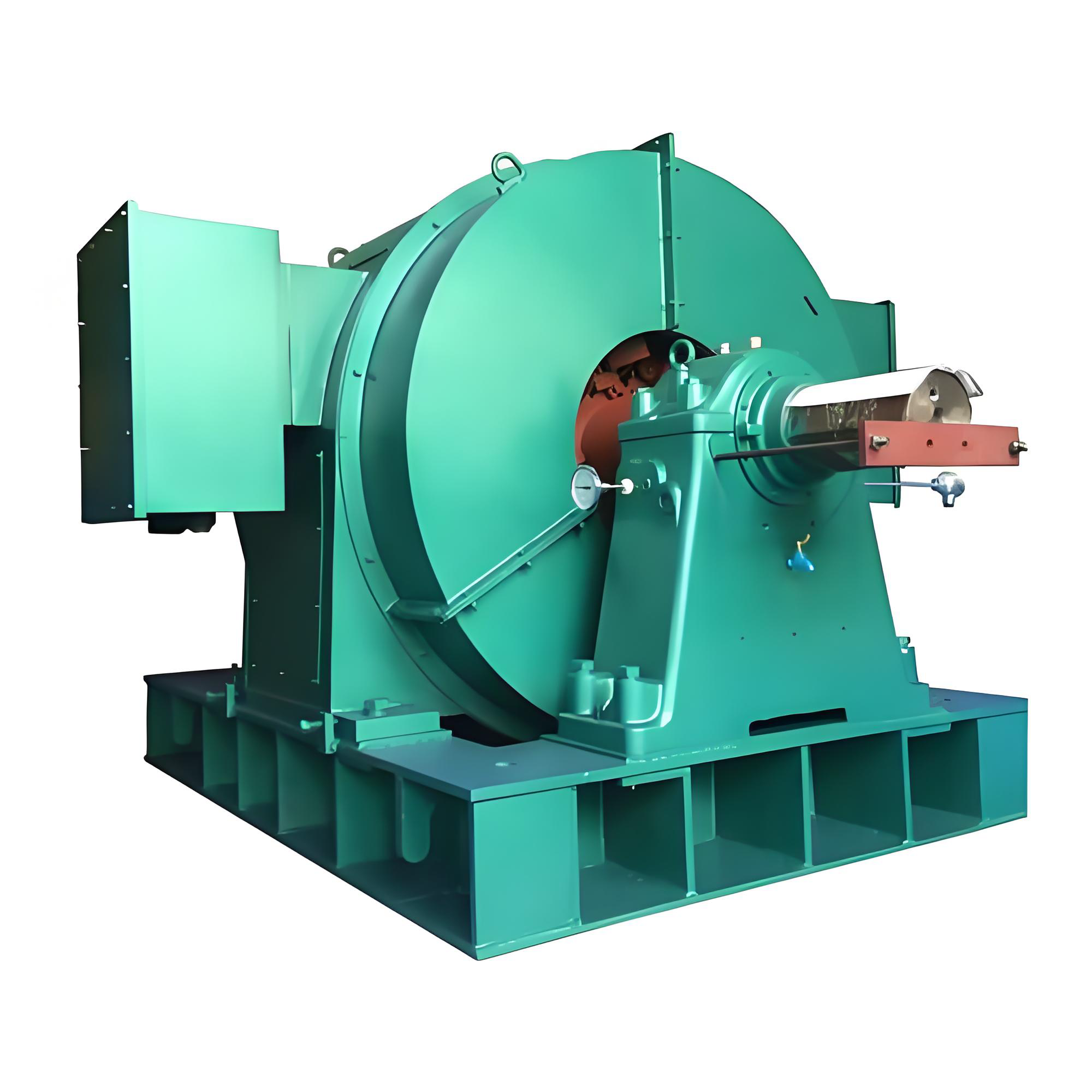

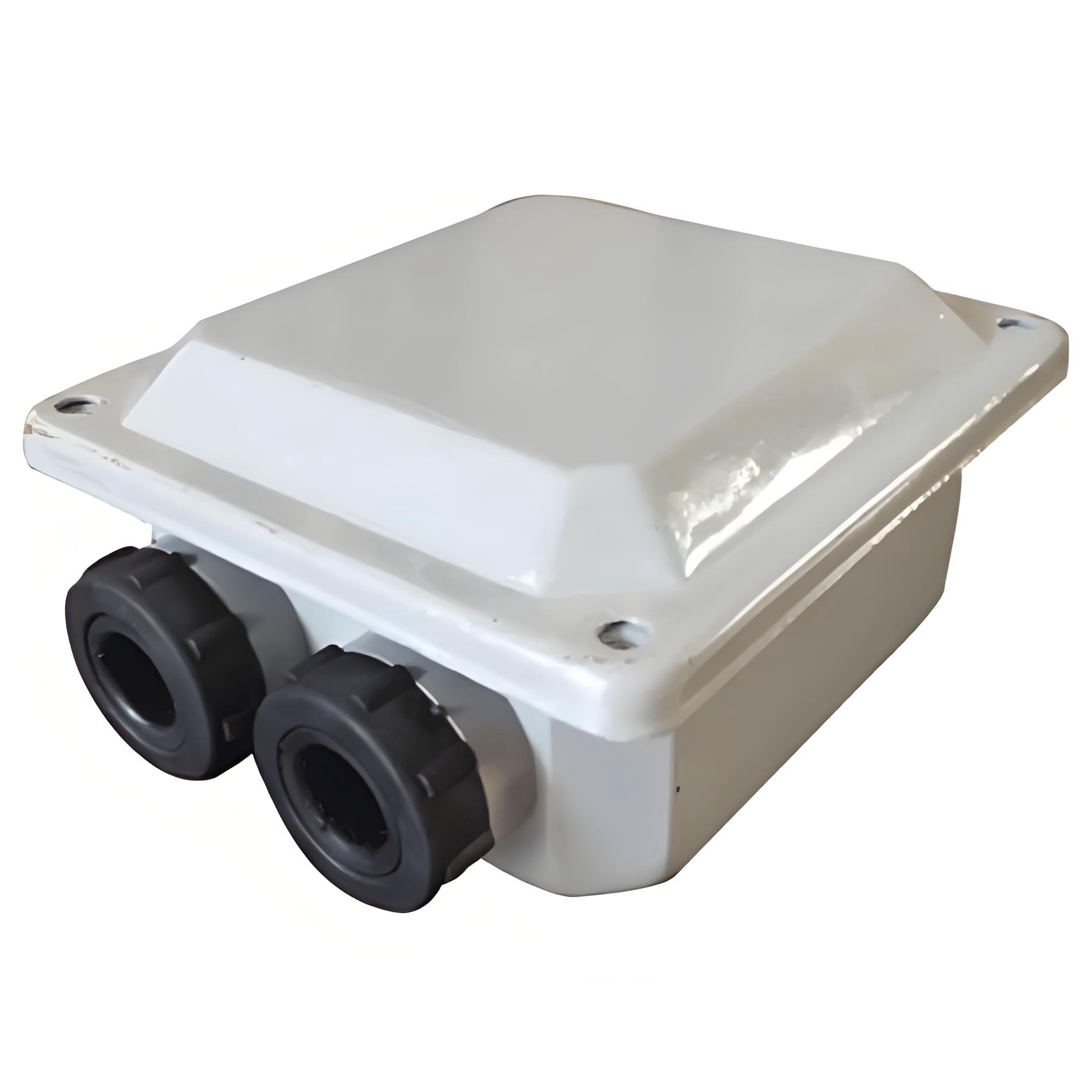

The motor fan cover is designed to protect the cooling fan of an electric motor while allowing efficient airflow. It ensures safety by preventing foreign objects from entering the fan area and maintains optimal motor cooling for long-lasting performance.

SIMO Motor Fan Covers: Optimal Cooling and Quiet Operation

In the SIMO Motor product lineup, fan covers may appear as simple structural components, but they play a critical role in motor cooling efficiency, protection, and longevity.

SIMO Motor fan covers are designed for a wide range of motors to provide efficient cooling and safety protection. With scientific ventilation design and precision manufacturing, these fan covers enhance heat dissipation, maintain optimal motor temperature, and ensure stable operation. Constructed with high-quality materials and innovative designs, they offer strong protection, efficient airflow, robust structure, aesthetic appearance, and easy installation, widely applied in industrial fans, motors, and ventilation systems.

Product Overview and Core Functions

SIMO Motor fan covers are key components of the motor cooling system and protective enclosure, providing effective heat dissipation while preventing foreign objects from entering the motor. The optimized ventilation holes and sturdy frame design maximize airflow and structural strength. SIMO offers multiple materials, sizes, and mounting options to meet diverse motor requirements, with each design rigorously tested for reliable performance.

Key Features and Performance Advantages

1. Noise Reduction Design

- Noise-Reducing Structure: Separate inlet and outlet airflow areas with partitions to minimize noise propagation.

- Sound-Absorbing Materials: Integrated at high-radiation points to reduce operational noise.

- Streamlined Airflow: Partition and guide plates are aerodynamically shaped to reduce resistance and prevent temperature rise while minimizing noise.

2. Efficient Cooling Performance

- Optimized Ventilation System: Strategic hole layout and airflow guidance ensure rapid heat dissipation during motor operation.

- Hybrid Ventilation Technology: Combines axial and radial airflow systems, adjusting core length per section to enhance cooling efficiency.

- Intelligent Air Duct Design: Internal ducts remove heat smoothly while reducing noise, maintaining cooling efficiency under IP24W protection.

3. Robust and Durable Structure

- High-Quality Materials: Constructed from high-strength steel or premium aluminum alloy for structural integrity and corrosion resistance.

- High Protection Level: Standard IP55, resisting dust and water ingress for harsh industrial conditions.

- Temperature Resistance: Suitable for ambient temperatures up to 40℃, maintaining stability in high-heat industrial environments.

Technical Parameters and Specifications

| Parameter | Specification |

|---|---|

| Frame Size | 80–355 (Y series, YGM series low-voltage motors) |

| Protection Level | IP55 (customizable higher) |

| Insulation Class | F |

| Operating Temperature | -25℃ to +40℃ |

| Relative Humidity | ≤90% |

| Cooling Method | Self-cooling, forced-air cooling (model-dependent) |

Product Series:

- Standard Fan Cover Series: Balanced cooling performance, cost-effective, ideal for most industrial motors.

- Low-Noise Series: Features sound-absorbing materials and noise-reducing structure for noise-sensitive applications.

- High-Protection Series: Enhanced dust and water protection for dusty, humid, or harsh environments.

- VFD Motor Series: Specifically designed for variable frequency motors to maintain efficient cooling across speed ranges.

Application Areas and Industry Solutions

1. Industrial Manufacturing

- Power Industry: Boilers, dust collectors, and generators for stable operation.

- Metallurgy: Sintering fans, dust removal, and smelting ventilation under high temperature and dust.

- Building Materials: Cement, glass, and ceramics production requiring reliable cooling.

2. General Industrial and Civil Applications

- Industrial Fans: Centrifugal, axial, and ventilation systems.

- Motor Support: Cooling covers for continuous motor operation without overheating.

- Pumps and Compressors: Efficient cooling and protection for long-term reliability.

3. Special Environment Applications

- High Temperature: Boiler fans, hot flue gas systems.

- Dusty Conditions: Dust collectors, mining ventilation.

- High Humidity: Underground projects, offshore platforms.

Selection and Installation Guide

1. Selection Considerations

- Motor Parameters: Match fan cover to motor type, power, speed, and frame size.

- Environment: Consider temperature, humidity, dust, and corrosive substances.

- Cooling Needs: Determine ventilation area based on motor heat output and duty cycle.

- Space Constraints: Ensure adequate installation space to avoid interference.

2. Installation Tips

- Inspection: Check for deformation and secure welds before installation.

- Alignment and Fixing: Ensure accurate alignment and secure attachment to prevent vibration.

- Sealing: Apply proper sealing measures to prevent airflow or moisture ingress.

Maintenance and Troubleshooting

1. Routine Maintenance

- Cleaning: Remove dust and oil from ventilation holes to maintain airflow.

- Corrosion Check: Inspect for rust or corrosion, especially in humid or corrosive environments.

- Connection Check: Ensure bolts and attachments are secure for structural stability.

2. Common Issues

- Blocked Ventilation: Clean airflow passages to restore cooling.

- Excessive Vibration: Tighten bolts or replace deformed covers.

- Early Corrosion: Use more corrosion-resistant materials or apply surface treatments.

Service and Support

- Technical Consultation: Guidance on selection and application.

- Customized Solutions: Tailored designs to meet specific requirements.

- After-Sales Guarantee: Quality assurance and reliable support.

- Inventory Support: Ample stock for urgent replacement needs.

SIMO Motor fan covers offer scientific design, premium materials, and precision engineering, making them ideal for motor cooling and protection. They deliver reliable performance and long service life for both standard industrial and harsh environments.

Choosing SIMO Motor fan covers ensures efficient cooling, quiet operation, and long-term reliability, providing optimal protection for your equipment.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206