Excerpt:

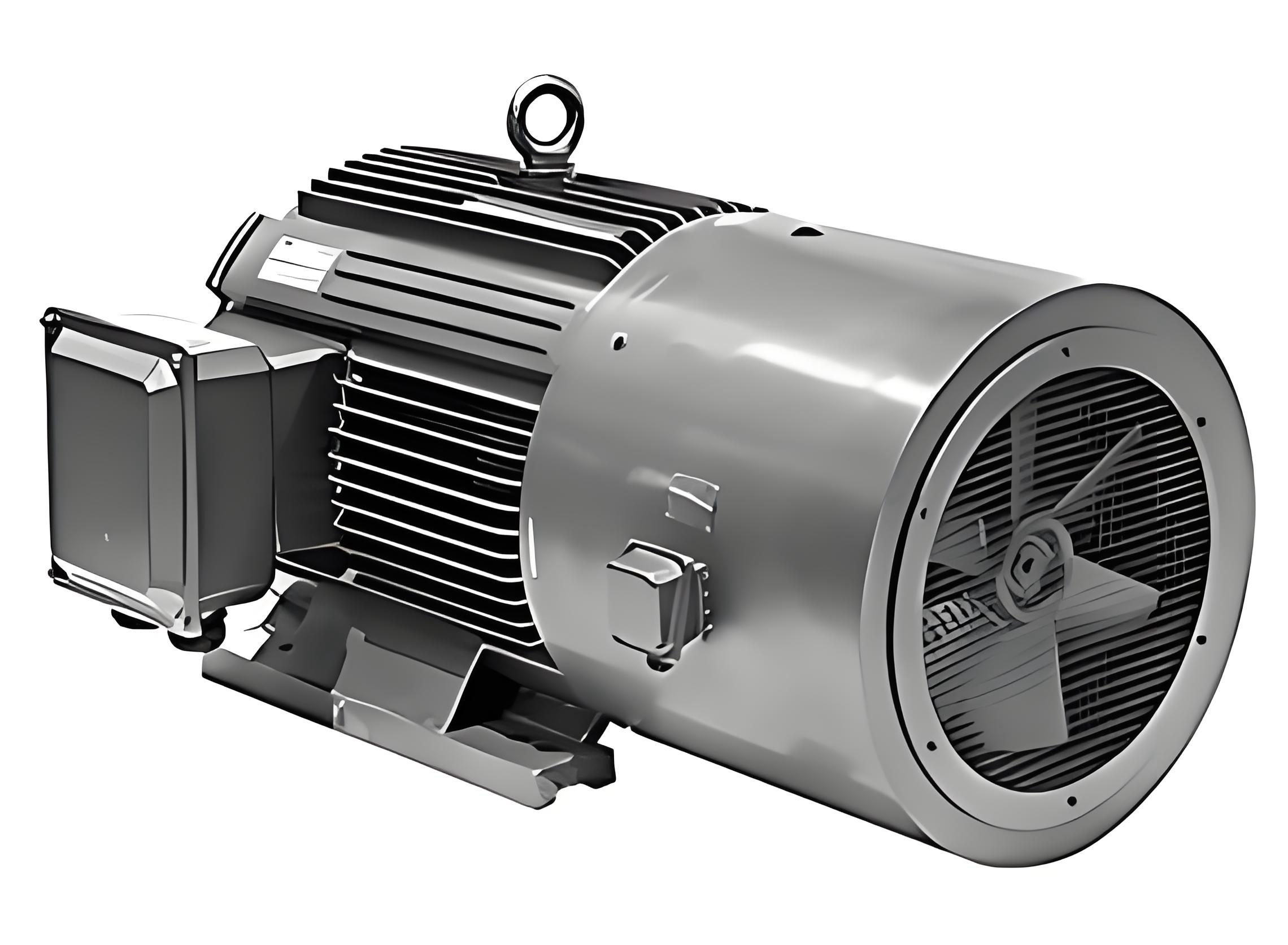

The YRQ series medium-sized asynchronous motor is designed for industrial applications requiring stable performance, high reliability, and strong load capacity. With robust construction and excellent operating characteristics, it is suitable for machinery such as compressors, pumps, fans, and various medium-duty industrial equipment.

YRQ Medium-Size Asynchronous Motor: Efficient and Reliable Industrial Power Solution

Product Overview

The YRQ Medium-Size Asynchronous Motor is designed as a core industrial power source, offering exceptional performance, high reliability, and robust operation for a wide range of heavy-duty machinery. Engineered for continuous industrial use, the YRQ series delivers stable torque, efficient energy consumption, and superior mechanical durability, making it the preferred choice for industries such as metallurgy, mining, petrochemicals, power generation, and general manufacturing.

Built with precision engineering and high-quality materials, YRQ motors ensure reliable start-up performance, low vibration, and long service life. The motors comply with national and international standards, including GB/T and IEC series regulations, ensuring consistent compatibility, safety, and operational efficiency across diverse industrial applications.

Key Technical Features

- High Starting Torque: Capable of delivering strong starting torque at reduced inrush current, minimizing impact on the power supply while efficiently starting heavy-load equipment.

- Stable Operational Performance: Optimized rotor and stator design ensures smooth operation with minimal vibration and low noise levels, enhancing workplace safety and comfort.

- Efficient Energy Use: Designed for high efficiency, the YRQ series helps reduce operating costs while supporting energy-saving initiatives.

- Durable Construction: Built with premium insulation and robust mechanical components, providing long-term reliability under continuous heavy-duty industrial conditions.

- Flexible Installation: Multiple mounting options, including foot-mounted and flange-mounted configurations, allow for seamless integration into existing systems.

Technical Parameters

The YRQ series motors cover a wide range of technical specifications to meet diverse industrial needs:

| Parameter | Specification |

|---|---|

| Frame Size | Medium frame (varies by model) |

| Rated Power | 5kW–200kW |

| Rated Voltage | 380V, optional 220V/400V/415V/660V |

| Rated Frequency | 50Hz (optional 60Hz) |

| Poles | 2, 4, 6, 8 |

| Protection | IP44/IP54 (depending on model) |

| Insulation Class | B or F |

| Cooling Method | IC411 (self-ventilated fan cooling) |

| Duty | S1 (continuous duty) |

| Mounting | IMB3, IMB5, IMB35, or customized |

Structural Design and Features

- Motor Housing: High-strength, fully enclosed design protects internal components against dust, moisture, and mechanical impact.

- Stator & Rotor: Precision-wound stator and rotor windings with high-grade insulation ensure reliable electrical and mechanical performance.

- Cooling System: IC411 self-ventilated fan design maintains optimal temperature under continuous operation.

- Terminal Box: Flexible wiring options, including top, left, or right exit, allow easy installation in confined spaces.

Applications

YRQ Medium-Size Asynchronous Motors are widely used across industrial sectors for driving heavy-load equipment:

Heavy Industry:

- Mining: Crushers, hoists, conveyor systems

- Metallurgy: Rolling mills, compressors

- Power Generation: Fans, pumps, auxiliary machinery

General Industrial Applications:

- Conveyors and material handling equipment

- Agricultural machinery

- Manufacturing and processing machinery requiring continuous reliable operation

Special Conditions:

- Operations requiring high starting torque

- Environments needing energy-efficient and low-noise motors

- Heavy-duty machines with variable speed requirements

Advantages and Benefits

- Operational Reliability: Robust construction ensures stability under demanding conditions.

- Energy Efficiency: Optimized design reduces energy consumption and operating costs.

- Maintenance-Friendly: Modular design and high-quality insulation reduce downtime and maintenance frequency.

- Long Service Life: Durable materials and precision engineering extend operational life.

Installation and Operation

- Environmental Requirements: Suitable for industrial environments without corrosive, flammable, or explosive gases. Ambient temperature -15°C to +40°C; altitude ≤1000m.

- Transmission: Compatible with coupling, gear, or pulley drives.

- Electrical Connection: Follow motor nameplate and wiring diagrams for correct installation; ensure proper grounding.

Service and Support

- Quality Assurance: Manufactured under strict quality management systems, fully compliant with GB/T and IEC standards.

- Testing: Each motor undergoes comprehensive factory performance tests to ensure reliability.

- After-Sales Service: Technical support for motor selection, installation, and troubleshooting, with long-term maintenance assistance.

YRQ Medium-Size Asynchronous Motors deliver stable, efficient, and reliable power for industrial heavy-duty applications. By combining advanced technology, precise engineering, and strict quality control, every YRQ motor guarantees safe and continuous operation, helping industries achieve high productivity, energy savings, and operational excellence.

Choosing YRQ motors ensures dependable performance, long-term reliability, and comprehensive technical support for industrial applications worldwide.

YRQ Medium-Size Asynchronous Motor: High-Efficiency and Reliable Industrial Power Solution

Product Overview

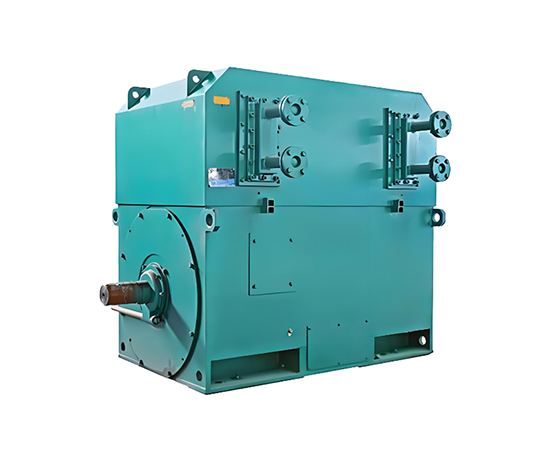

The YRQ Medium-Size Asynchronous Motor is a three-phase wound-rotor motor designed with advanced electromagnetic engineering and high-quality materials. It features a robust structure, reliable operation, and convenient maintenance. The series strictly complies with national standards such as GB/T 13957-2022 for large three-phase asynchronous motors, and its power ratings and mounting dimensions meet international standard specifications, ensuring easy integration and replacement in existing equipment.

As a core industrial power source, the YRQ motor series is suitable for driving various heavy-duty machinery, including compressors, pumps, crushers, coal mills, rolling mills, and hoists. Its box-type welded steel frame ensures reliable performance across diverse operating environments, making it ideal for mining, mechanical, petrochemical, and power generation industries.

Key Technical Features

1. High-Efficiency and Energy-Saving Design

- Optimized electromagnetic design and low-loss materials significantly improve efficiency, reducing energy consumption and operating costs.

- Complies with GB755 and IEC standards, ensuring high performance and rapid return on investment compared to conventional motors.

2. Exceptional Operational Performance

- Wide Speed Range: Wound-rotor structure allows excellent starting and adjustable-speed capabilities.

- High Starting Torque: Delivers strong torque to meet heavy-load startup requirements.

- Low Vibration & Noise: Precision manufacturing ensures smooth operation with minimal vibration and noise.

3. Robust Structural Design

- High Protection Levels: Available in IP23, IP44, IP54, and IP55 depending on application requirements.

- Premium Insulation: F-class or H-class insulation ensures reliability and long service life.

- Enhanced Bearing System: Rolling or sliding bearings configured based on motor power and speed.

Technical Parameters

| Parameter Category | Specifications & Performance |

|---|---|

| Frame Size Range | H355–H630 |

| Rated Voltage | 6kV, 10kV, or customized |

| Rated Frequency | 50Hz or 60Hz |

| Protection Level | IP23, IP44, IP54, IP55 |

| Insulation Class | F-class, H-class |

| Cooling Method | IC01, IC611, IC81W |

| Duty | S1 (continuous operation) |

| Poles | 4P, 6P, 8P, 10P, 12P |

Performance Highlights:

- High-efficiency operation across wide load ranges.

- Stable performance under varying voltage conditions.

- High power factor reduces reactive power consumption and improves grid quality.

Structural Design and Configuration

1. Motor Body Structure

- Frame Design: Welded steel frame provides strength and light weight. Observation windows allow easy maintenance access.

- Stator: High-grade F-class insulated stator with secure winding fixation, vacuum pressure impregnation (VPI) ensures excellent insulation, mechanical strength, and moisture resistance.

- Rotor: Wound rotor with slip-ring structure, treated with VPI for long-term reliability.

2. Cooling System

- IC01: Air-cooled for IP23 protection motors.

- IC611: Air-to-air closed cooling for IP44 motors.

- IC81W: Air-to-water closed cooling for IP44 motors.

Applications

1. Heavy Industry

- Mining: Drives crushers, coal mills, hoists under harsh conditions.

- Metallurgy & Steel: Rolls, blowers, and other high-load equipment.

- Power Generation: Auxiliary equipment like fans and pumps.

2. General Industrial Applications

- Compressors and pumps for continuous industrial operation.

- Material handling: conveyors, transport machinery.

- Machine tools: stable drive for cutting and processing equipment.

3. Special Applications

- High starting torque requirements.

- Power supply limitations prevent the use of squirrel-cage motors.

- Frequent or prolonged start operations.

- Small-range speed adjustment applications.

- Synchronization with mechanical "electric shafts" or special process requirements.

Advantages and Value

1. Operational Reliability

- Robust welded box structure withstands mechanical and thermal stresses.

- High-quality materials and precision engineering ensure long-term stable operation.

- Comprehensive protection: PT100 temperature sensors on stator and bearings, continuous lubrication system.

2. Energy Efficiency & Economic Benefits

- Reduces operating costs via high efficiency.

- Optimized energy utilization with high power factor and low energy loss.

- Lower lifecycle costs due to durability and low maintenance requirements.

3. Maintenance Convenience

- Easy access to internal components by removing coolers or protective covers.

- Modular design reduces maintenance complexity and spare part inventory.

- Long service life due to premium insulation and design optimization.

Installation and Operation

1. Environmental Requirements

- Ambient temperature: -15°C to +40°C.

- Clean industrial environment with no corrosive, explosive, or excessively dusty conditions.

- Maximum installation altitude: 1000m.

- Standard installation: Horizontal with feet (IMB3).

2. Installation and Commissioning

- Solid, flat foundation to support motor weight and operational forces.

- Precise alignment with driven machinery using couplings.

- Correct electrical connections per motor nameplate and wiring diagrams; proper grounding required.

Service and Technical Support

Quality Assurance:

- Manufactured under GB/T 13957-2022, GB755, and IEC standards.

- Multiple inter-turn voltage tests and insulation testing for each motor.

- Comprehensive factory performance testing ensures reliability.

After-Sales Service:

- Expert guidance on motor selection, installation, and operation.

- Rapid response to service requests and technical issues.

- Long-term technical support and maintenance services.

YRQ Medium-Size Asynchronous Motors combine advanced technology, high-efficiency operation, and robust reliability to provide a safe, stable, and efficient power solution for industrial heavy-duty applications.

Choosing YRQ motors guarantees dependable performance, long service life, and comprehensive technical support, driving energy efficiency and industrial productivity.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206