Excerpt:

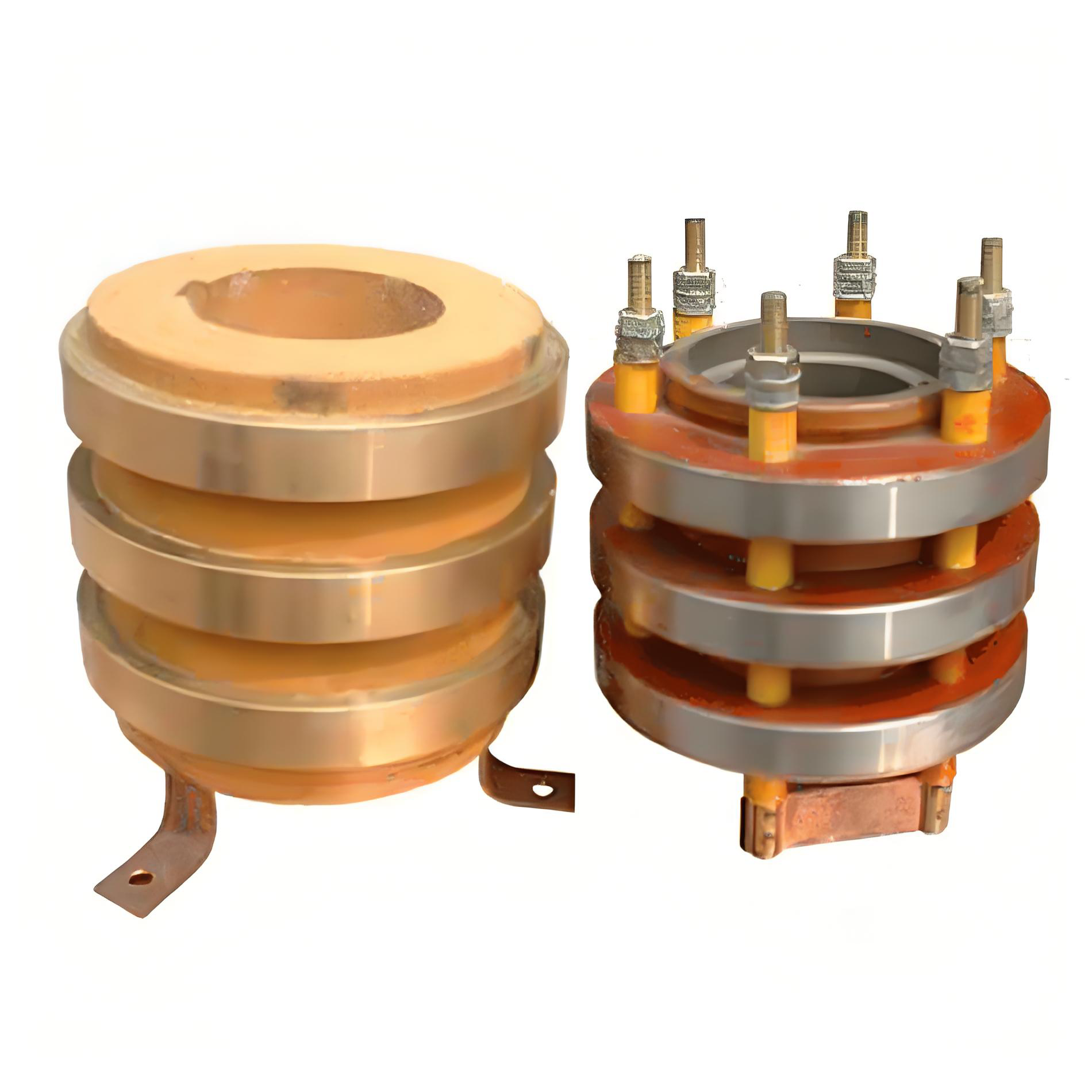

The motor insulator is a critical component designed to prevent electrical leakage and ensure safe operation of electric motors. Made from high-quality insulating materials, it provides reliable electrical isolation and enhances the motor's performance and longevity.

西玛电机绝缘子:电力设备安全运行的可靠保障

SIMO Motor Insulators: Reliable Protection for Safe Operation of Electrical Equipment

In electrical systems and motors, insulators serve as critical components that provide both mechanical support and electrical isolation, forming a vital safeguard for the stable and safe operation of power equipment.

Product Overview

SIMO Motor insulators are specialized insulation components designed to combine mechanical support with electrical insulation in power systems. They are essential for supporting and securing live conductors while maintaining effective isolation from grounded parts, playing a crucial role in generation, transmission, and distribution of electrical power.

Manufactured from high-quality porcelain, toughened glass, or composite polymer materials, SIMO insulators undergo precise production processes and strict quality control to ensure excellent electrical performance, outstanding mechanical strength, and long-lasting environmental adaptability. Products comply with GB/T 772-2005 "Technical Conditions for High Voltage Insulator Porcelain" and international standards such as IEC 60383, providing reliable insulation solutions for various power applications.

Core Technical Features

1. Electrical Performance

- High Insulation Strength: Made from premium insulation materials with high volume and surface resistivity.

- Excellent Arc Resistance: Withstands system overvoltage and lightning surges.

- Stable Dielectric Properties: Maintains consistent insulation under both power frequency and impulse voltage.

- Superior Pollution Flashover Resistance: Special shed design enhances insulation reliability in polluted environments.

2. Mechanical Performance

- High Structural Strength: Supports conductor tension, wind load, and ice load.

- Excellent Bending Resistance: Maintains integrity under harsh climatic conditions.

- Seismic Resistance: Designed to withstand earthquake conditions.

- Thermo-Mechanical Stability: Retains dimensional stability and mechanical strength under temperature variations.

3. Environmental Adaptability

- Weather Resistance: Resists UV exposure and temperature fluctuations.

- Corrosion Resistance: Maintains performance under acid rain, salt spray, and other corrosive environments.

- Anti-Aging Design: Long service life through aging-resistant materials and processes.

- Wide Temperature Range: Operates reliably from -40℃ to +40℃.

Technical Parameters

| Parameter | Specification |

|---|---|

| Rated Voltage | 10 kV – 1000 kV (model-dependent) |

| Mechanical Breaking Load | 70 kN – 550 kN (model-dependent) |

| Power Frequency Withstand Voltage | Configured per voltage level |

| Impulse Withstand Voltage | Configured per voltage level |

| Creepage Distance | Determined by pollution level |

| Standards | GB/T 772, IEC 60383 |

Product Types and Applications

1. By Material

- Porcelain Insulators: Excellent chemical and thermal stability, high mechanical strength.

- Glass Insulators: Self-extinguishing upon breakage, easy inspection, long service life.

- Composite Insulators: Lightweight, excellent pollution resistance, high mechanical strength.

2. By Structure

- Pin-Type Insulators: For straight or slightly angled transmission towers.

- Suspension Insulators: For high-voltage and extra-high-voltage transmission lines.

- Post Insulators: For substations and distribution equipment.

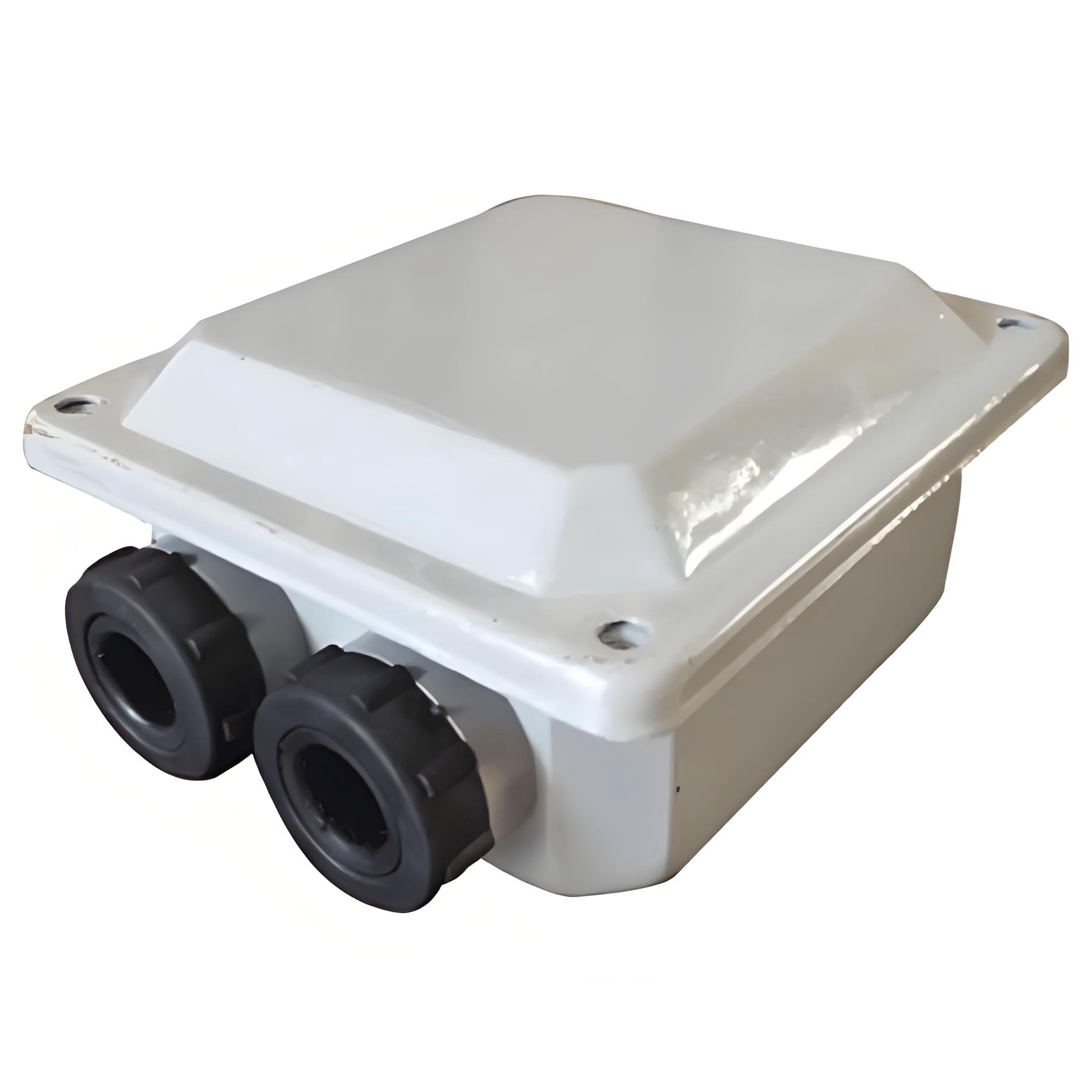

- Bushing Insulators: For conductor penetration through grounded barriers.

3. By Voltage Level

- Low Voltage: ≤1 kV

- Medium Voltage: 3 kV – 35 kV

- High Voltage: 110 kV – 330 kV

- Extra-High Voltage: ≥500 kV

Application Areas

1. Power Transmission Systems

- Overhead Transmission Lines: Insulation and support for various voltage levels.

- Substation Equipment: For transformers, circuit breakers, disconnectors, etc.

- Distribution Networks: Insulation protection for distribution lines and equipment.

2. Electrified Railway Systems

- Traction Power Systems: Insulation and support for railway catenaries.

- Substation Equipment: Insulation for railway substation installations.

3. Industrial Power Equipment

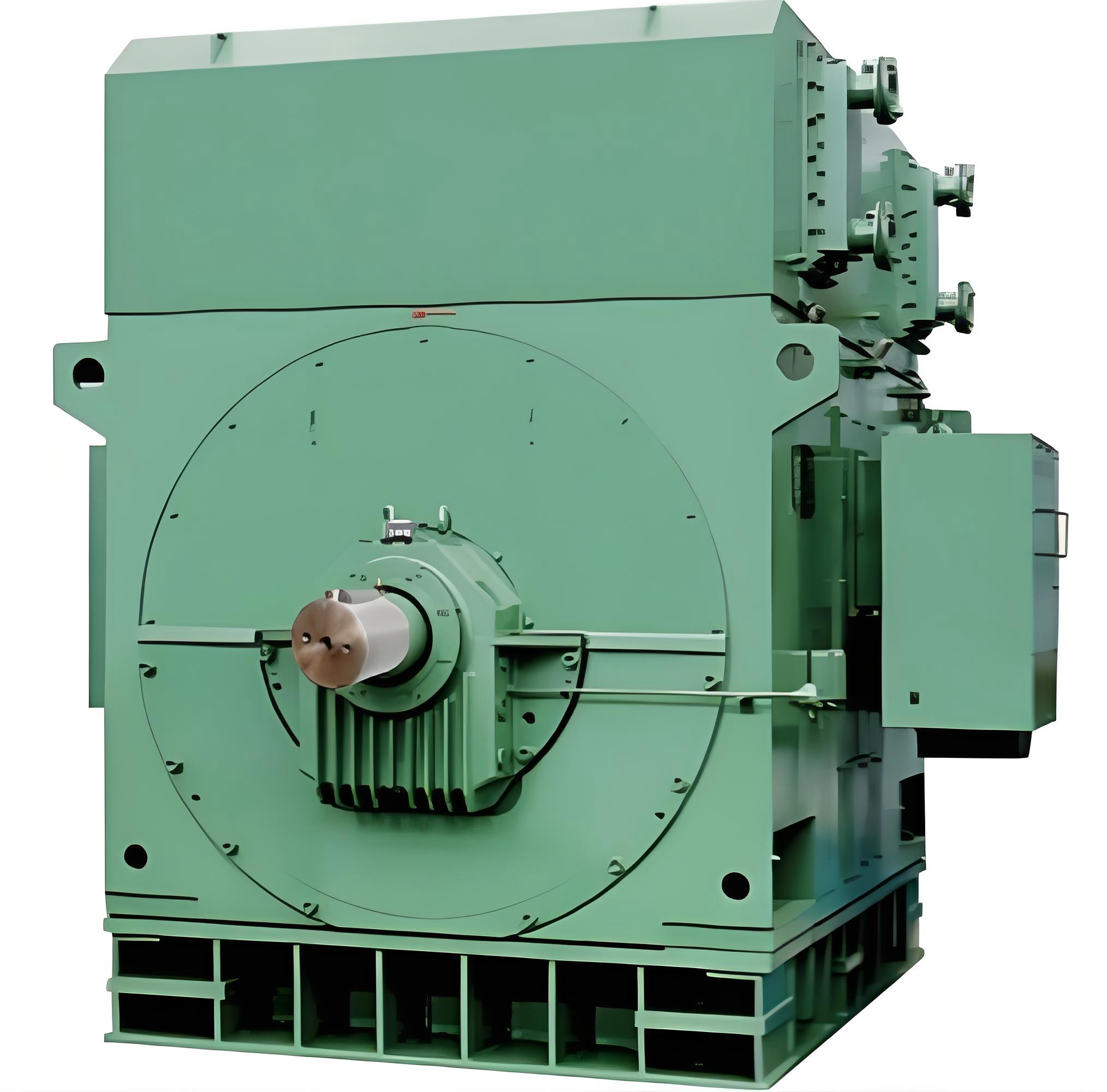

- Large Motors: Insulation and support for medium and large motors.

- Power Devices: Insulation and mechanical support for various electrical equipment.

- Special Environments: Mining, metallurgy, and other harsh industrial applications.

Product Advantages

1. Reliability

- Strict Quality Control: End-to-end monitoring from raw materials to finished products.

- Advanced Testing: Ensures all performance parameters meet or exceed standards.

- Proven Long-Term Performance: Products validated under extended operational conditions.

2. Technical Innovation

- Continuous R&D: Development of new insulator types and process improvements.

- Material Innovation: Advanced composite materials for enhanced performance.

- Structural Optimization: CAD-driven design for optimized mechanical and electrical performance.

3. Comprehensive Service

- Professional Technical Support: Product selection and installation guidance.

- Rapid Response System: Efficient after-sales support and troubleshooting.

- Customized Solutions: Tailored products to meet unique client requirements.

Selection Guide

- Considerations: Voltage level, mechanical load, environmental conditions, installation location.

- Steps: Identify conditions → Choose insulator type → Determine specifications → Verify suitability.

Installation and Maintenance

- Installation: Inspect for cracks or defects, follow manual guidelines, control torque, ensure secure connections.

- Maintenance: Regular inspections, surface cleaning, defect handling, periodic preventive tests.

Service and Technical Support

- Consultation: Product selection and application guidance.

- Installation Assistance: Detailed instructions and technical support.

- Operation & Maintenance: Training and operational guidance.

- After-Sales Guarantee: Full-quality assurance and support.

SIMO Motor insulators provide high-quality, reliable, and durable insulation solutions for electrical power systems. Choosing SIMO insulators ensures safe, stable operation and long-term reliability in power generation, transmission, and distribution applications.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206