Excerpt:

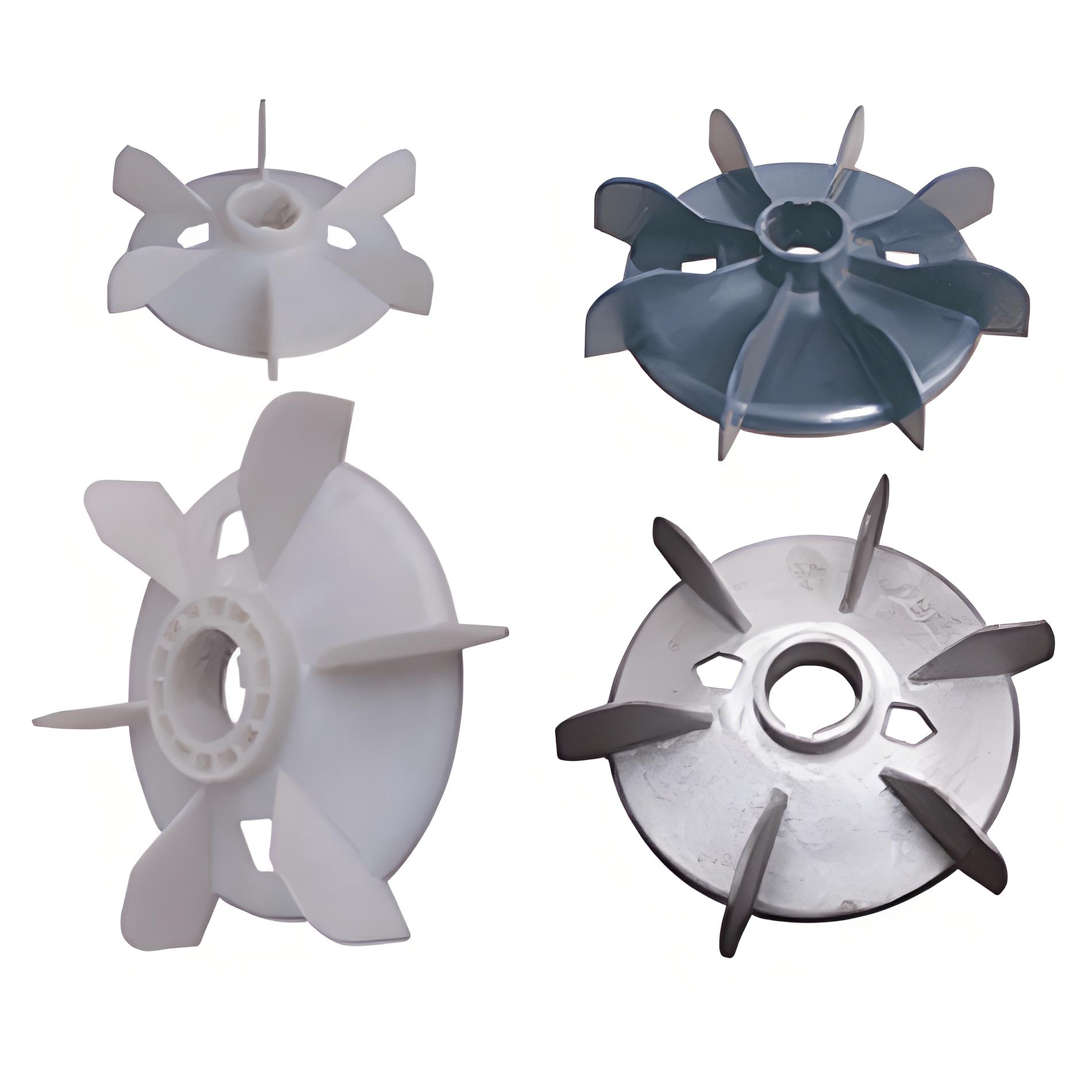

The motor fan blade is designed to provide efficient cooling for electric motors by ensuring optimal airflow. Made from durable materials, it helps prevent overheating, improves motor performance, and extends the service life of the motor.

SIMO Motor Blades: Exceptional Performance and Long-Lasting Durability

As a core component of electric motors, SIMO Motor blades deliver excellent cooling efficiency and stable, long-term operation, making them an ideal choice for various industrial equipment and motor products.

Designed for efficient heat dissipation, SIMO Motor blades use advanced aerodynamic engineering and precise manufacturing processes to enhance motor cooling, ensuring optimal operating temperatures. Constructed with premium materials and innovative designs, these blades feature corrosion resistance, high strength, low noise, high efficiency, aesthetic appeal, and easy installation, widely applied in industrial fans, motors, and ventilation systems.

Overview and Core Functionality

SIMO Motor blades are essential to the motor cooling system, removing heat generated during operation via forced air convection. They prevent overheating and maintain motors within optimal temperature ranges.

Available in plastic, aluminum, and iron materials, each type offers unique advantages for different environments. The blades are aerodynamically optimized, generating higher airflow and pressure at the same speed while significantly reducing noise. Dynamic balancing ensures stable operation at high speeds, minimal vibration, and extended motor lifespan.

Key Technical Features

1. Premium Materials and Robust Structure

- Material Options: PA6.6 reinforced plastic, aluminum alloy, and iron blades. Plastic blades combine the strength of metal with lightweight properties.

- Innovative Design: Integrated hub and blade construction with uniform distribution; permanent joining (welding or bonding) ensures overall balance.

- Surface Treatment: Metal blades treated for corrosion and wear resistance, suitable for harsh environments.

2. Superior Performance and Efficient Cooling

- High Cooling Efficiency: Optimized blade angles and surfaces maximize airflow and pressure.

- Low Noise Operation: Noise reduction technology ensures smooth and quiet performance.

- Energy Saving: Aerodynamic design minimizes rotational resistance, reducing power consumption.

3. Long Service Life and Reliability

- High Strength and Wear Resistance: Treated blade surfaces resist abrasion even in dusty environments.

- Dynamic Balance Assurance: High-standard balancing minimizes vibration and noise during high-speed operation.

- Environmental Adaptability: Operating range from -20°C to 60°C, with some models suitable for wider temperature ranges.

Technical Specifications and Models

| Parameter | Specification |

|---|---|

| Material | Plastic (PA6.6), Aluminum, Iron |

| Applicable Motors | Y-Series: 80, 90, 100, 112, 132, 160, 180, 200, 225, 250, 280 |

| Operating Temperature | -20°C to +60°C (model-dependent) |

| Airflow | Up to 1140 m³/h (depending on model) |

| Noise Level | Optimized; varies by model |

Product Series:

- Standard Blades: Suitable for general industrial applications; balanced performance and cost-effective.

- High-Temperature Blades: Special materials and design for high-temp environments like boiler or exhaust fans.

- Corrosion-Resistant Blades: Treated for chemical or metallurgical environments.

- High-Strength Wear-Resistant Blades: Hardened surface (HRC60-70) extends lifespan 3×, ideal for dusty conditions.

Applications

1. Industrial Manufacturing

- Power Industry: Cooling for boilers, dust collectors, and generator systems.

- Metallurgy: Sintering and dust collector fans in high-temperature, high-dust environments.

- Building Materials: Cement, glass, and ceramics production requiring reliable ventilation and cooling.

2. General Industrial & Commercial

- Industrial Fans: Centrifugal, axial, and ventilation fans.

- Motor Cooling: Efficient heat dissipation for various motor types, ensuring continuous operation.

- Commercial Ventilation: Large exhaust fans, water-cooled fans, and factory cooling systems.

3. Special Environments

- High Temperature: Boilers, hot flue gas handling, and high-temp industrial settings.

- High Dust: Dust collector and mining ventilation equipment.

- Corrosive Atmospheres: Chemical processing and wastewater systems.

Selection and Installation

1. Selection Considerations

- Motor Specifications: Match blade size to motor model, power, speed, and frame size.

- Operating Environment: Assess temperature, humidity, dust, and corrosive exposure for material choice.

- Cooling Requirements: Determine airflow and pressure needs to select proper blade type.

- Space Constraints: Ensure adequate installation space and clearance.

2. Installation Guidelines

- Pre-Installation Check: Verify blades are undamaged and rotate freely.

- Alignment and Balance: Ensure proper alignment with motor shaft; avoid wobbling.

- Proper Fastening: Tighten according to recommended torque to prevent stress or loosening.

Maintenance and Troubleshooting

1. Routine Maintenance

- Cleaning: Remove dust and debris from blades to maintain cooling efficiency.

- Wear Inspection: Check leading and trailing edges for excessive wear.

- Balance Verification: Perform dynamic balancing after prolonged use or replacement.

2. Common Issues

- Excessive Vibration: Clean and rebalance blades if uneven deposits or imbalance occurs.

- Abnormal Noise: Inspect for foreign objects or bearing wear; replace damaged components.

- Reduced Airflow: Clean or replace blades if deformed or blocked.

Service and Support

SIMO Motor provides full support for blade products:

- Technical Consultation: Assistance with product selection and application.

- Custom Solutions: Design and manufacture specialized blades for unique requirements.

- After-Sales Assurance: Quality guarantee and service support.

- Stock Availability: Large inventory ensures immediate availability of blades and accessories.

SIMO Motor Blades combine innovative design, premium materials, and precise manufacturing to provide reliable cooling solutions for motors and ventilation equipment. From general industrial use to extreme environments, these blades deliver consistent performance and long service life.

Choosing SIMO Motor Blades ensures efficient cooling, operational reliability, and extended equipment lifespan, providing the optimal solution for industrial and commercial ventilation needs.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206