Excerpt:

The motor end cover and flange are essential components that protect the motor’s internal parts and provide structural support. They ensure proper alignment, enhance mechanical stability, and contribute to the motor’s overall durability and performance.

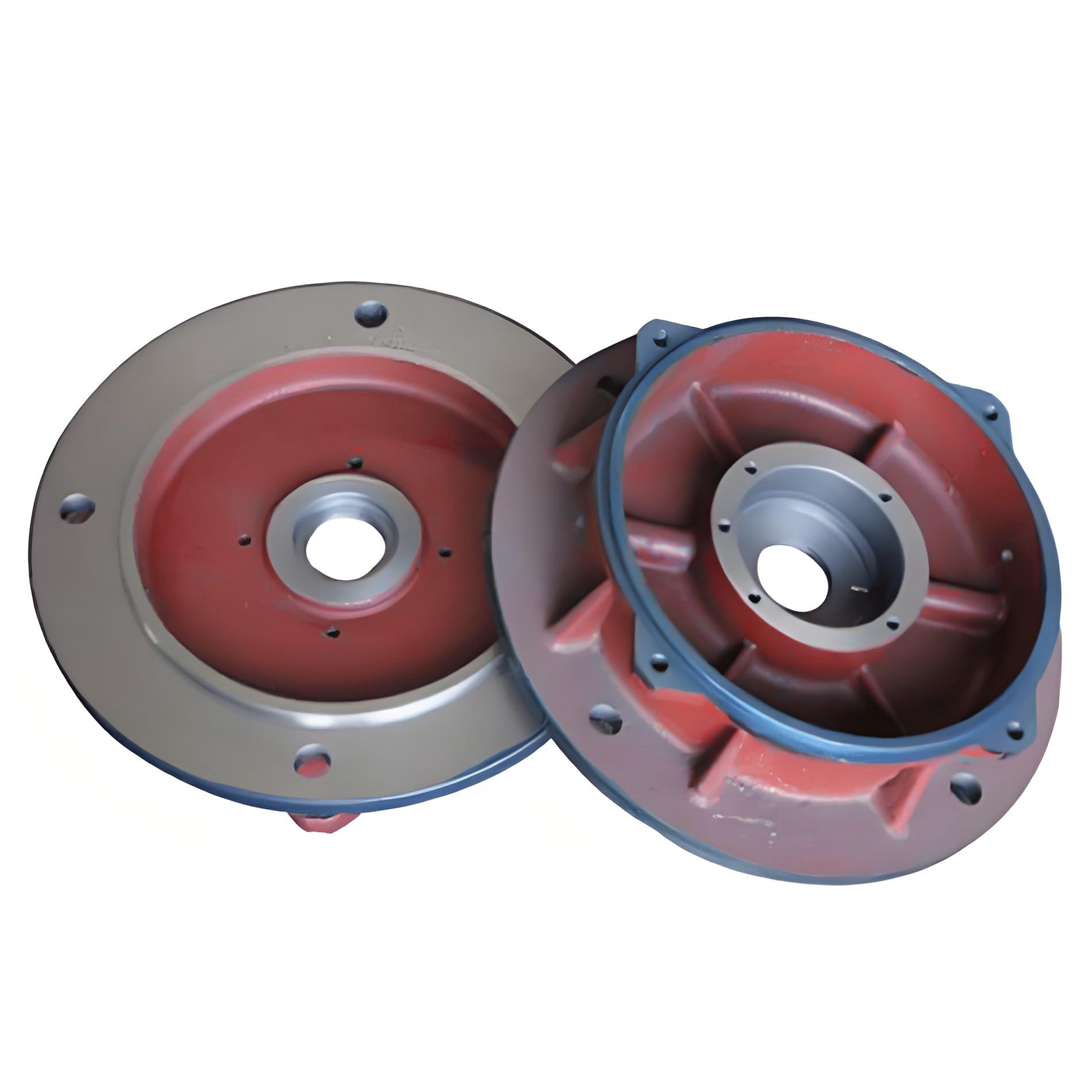

SIMO Motor End Covers & Flanges: Precision Protection and Efficient Power Transmission Components

In motor systems, end covers and flanges, while not core electromagnetic components, are essential for ensuring stable motor operation.

SIMO Motor end covers and flanges are critical mechanical components of motor construction, serving key roles in sealing protection and structural support. Manufactured from premium materials with precise engineering, each end cover and flange delivers exceptional mechanical strength, accurate dimensional tolerances, and long-lasting durability, providing a solid foundation for overall motor performance.

01 Product Overview: Structural Support and Sealing Barrier

End covers and flanges form the external support system and internal sealing environment of motors.

- End Covers: Mounted at both ends of the motor frame, they support bearings, protect internal components, and prevent contaminants from entering. SIMO Motor end covers feature high-strength materials and optimized designs for stability in harsh conditions.

- Flanges: Serve as the interface between the motor and driven equipment, typically featuring bolt holes and locating features for precise alignment and secure mounting. Precision machining ensures perfect mating, torque transmission, and load-bearing capability.

SIMO Motor offers various sizes, materials, and installation options to meet the needs of general industrial equipment and specialized applications.

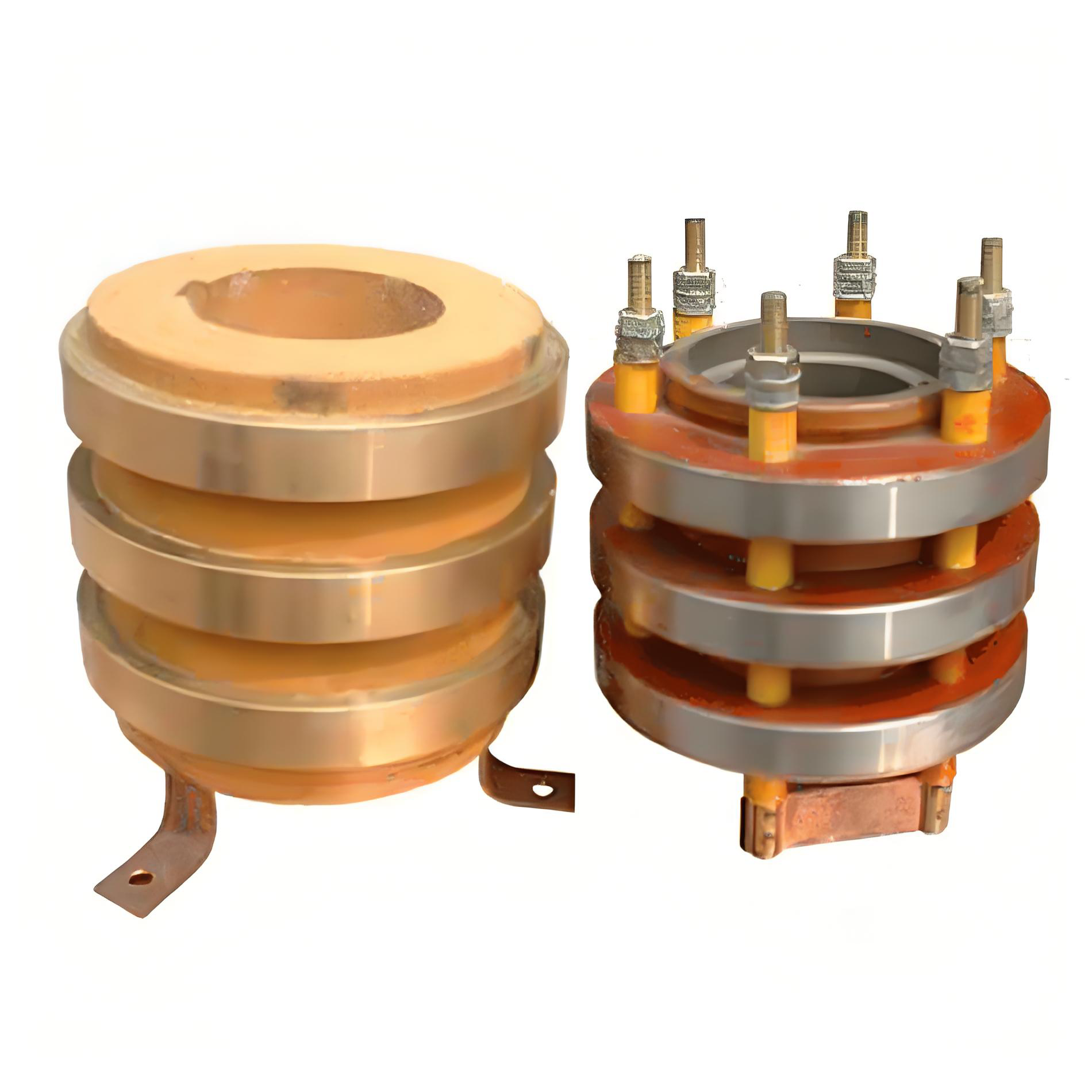

02 Core Functions: Multi-Purpose Reliability

End Cover Functions:

- Bearing Support & Alignment: Precise bearing housing reduces vibration and noise.

- Sealing Protection: Prevents dust, water, and contaminants from entering the motor.

- Heat Dissipation Assistance: Designs increase surface area for improved cooling.

- Structural Reinforcement: Enhances rigidity, impact resistance, and vibration tolerance.

Flange Functions:

- Equipment Connection: Standardized interfaces for reliable motor-to-equipment mounting.

- Power Transmission: Efficient torque transfer and load-bearing.

- Installation Convenience: Simplifies assembly and maintenance.

- Vibration Reduction: Reduces transmitted vibration and operational noise.

03 Technical Features: Precision Engineering for Superior Performance

Structure & Material Selection:

- High-Strength Materials: End covers in premium cast iron or aluminum; flanges in cast iron, steel, or aluminum based on application.

- Optimized Design: Finite element analysis for lightweight yet strong structures, improving power density.

- Precision Manufacturing: CNC machining ensures bearing seat and locating feature accuracy.

- Surface Treatment: Options include galvanizing, nickel plating, or blackening for corrosion resistance and aesthetics.

Performance Enhancement Technologies:

- Dynamic Balancing: Reduces vibration and noise.

- Heat Dissipation Optimization: Enhanced rib structures increase cooling efficiency.

- Vibration Control: Minimizes operational noise and ensures smooth performance.

- Sealing Technology: Multi-layer sealing ensures reliable operation in harsh conditions.

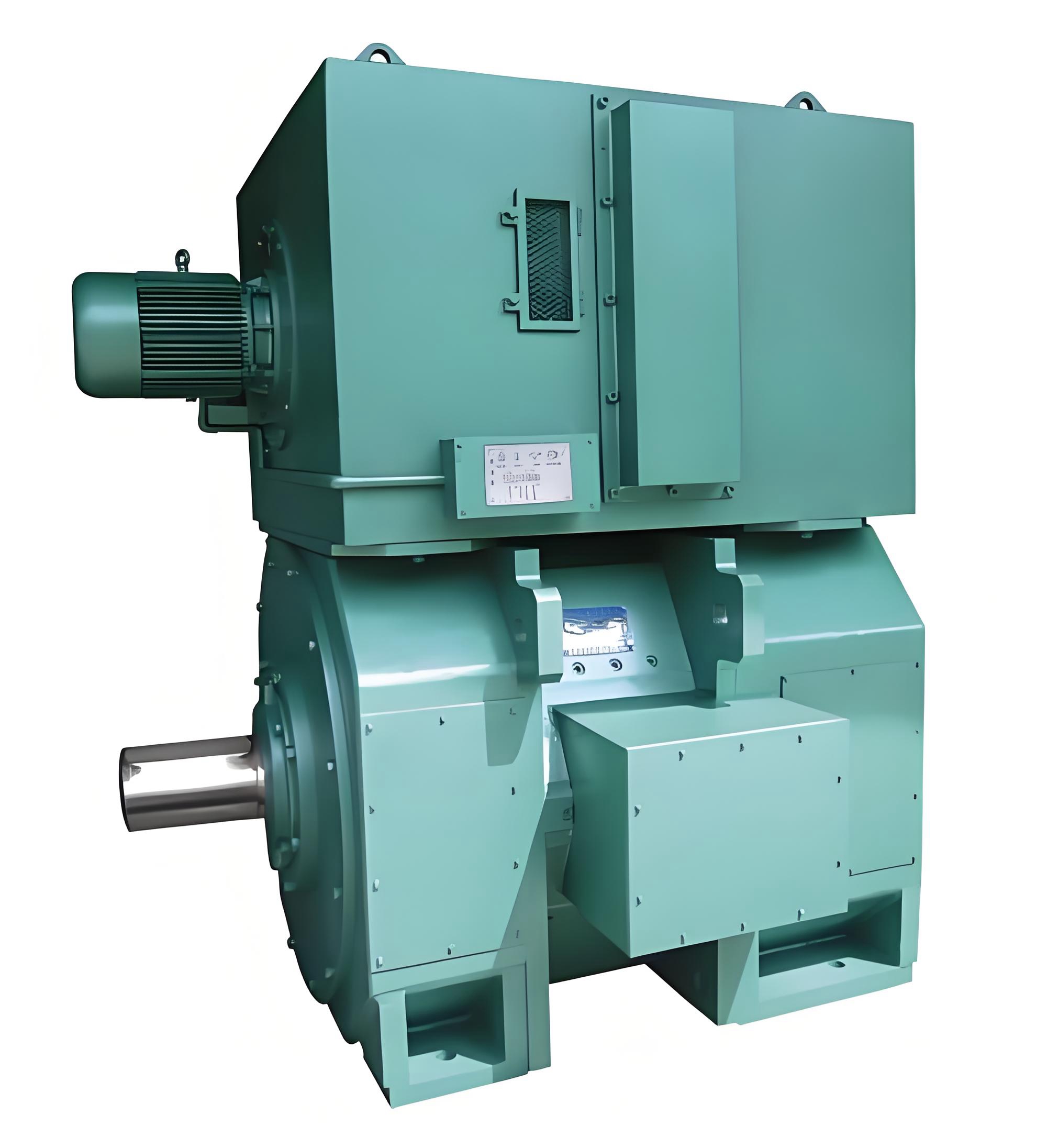

04 Applications: Wide Industrial Versatility

General Industrial Applications:

- Pumps: Centrifugal, vacuum, and submersible pumps requiring high seal integrity and corrosion resistance.

- Fans: Ventilation, exhaust, and compressor systems requiring dynamic balance and stability.

- Machine Tools: CNC machines, milling centers, and lathes demanding flange alignment precision and rigidity.

Specialized Applications:

- Variable Frequency Drives: End covers with independent ventilation for consistent cooling across frequency ranges.

- Heavy Machinery: Cranes, rolling mills, crushers requiring reinforced end covers and flanges for high-load and impact resistance.

- Rail Transport: Specialized motor end covers with direct-drive motor compatibility.

05 Technical Specifications

End Cover Parameters:

| Parameter | Specification |

|---|---|

| Applicable Frame Sizes | 80–355 (Y-Series, YGM low-voltage motors) |

| Bearing Seat Precision | H7 or higher |

| Mounting Bolt Holes | Standardized per frame size |

| Material & Thickness | Optimized for load, balancing strength and weight |

| Protection Level | IP54, IP55 or higher |

Flange Parameters:

| Parameter | Specification |

|---|---|

| Flange Diameter | Standardized by motor power series |

| Mounting Bolt Circle | Precisely controlled for alignment |

| Locating Diameter | H7 for accurate positioning |

| Flange Thickness | Optimized for torque and rigidity |

| Installation Holes | M6–M20 for various load requirements |

06 Selection Guide: Ensuring Optimal Fit

Factors to Consider:

- Load Characteristics: Select based on constant, variable, or shock load.

- Environmental Conditions: Temperature, humidity, corrosive exposure, and dust levels for material and protection selection.

- Installation Space: Choose dimensions compatible with space constraints.

- Rotational Speed: Select appropriate dynamic balance and bearing structure.

Selection Steps:

- Identify motor type, power, speed, and mounting method.

- Analyze application requirements for sealing, cooling, or corrosion resistance.

- Reference industry standards for compatible end cover and flange types.

- Consult SIMO Motor technical team for complex applications.

07 Service & Support

SIMO Motor provides comprehensive support for end covers and flanges:

- Technical Consultation: Product selection and application guidance.

- Custom Solutions: Tailored designs for unique requirements.

- After-Sales Guarantee: Quality assurance and service support.

- Fast Delivery System: Efficient supply chain ensures timely product availability.

SIMO Motor End Covers and Flanges are critical structural components that ensure long-term motor stability, reliability, and high-efficiency power transmission. With advanced design, precise manufacturing, and strict quality control, SIMO Motor delivers high-quality components that support industrial machinery for efficient and dependable operation.

Choosing SIMO Motor End Covers & Flanges means selecting trusted quality and professional technical support for optimal motor performance in any industrial application.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206