Excerpt:

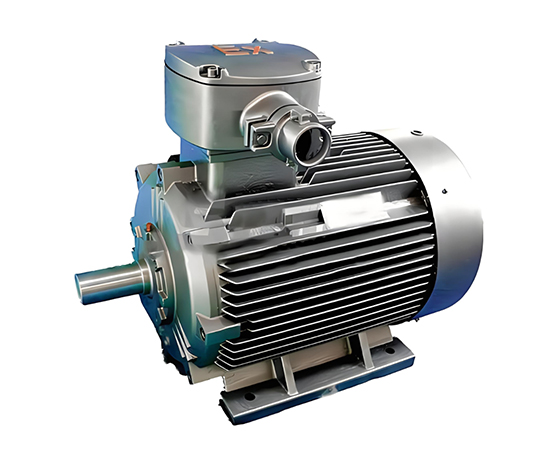

The Y Series IP23 low voltage three-phase asynchronous motor is designed for industrial applications requiring reliable and energy-efficient solutions. With high performance and durability, it's ideal for use in pumps, compressors, and various machinery.

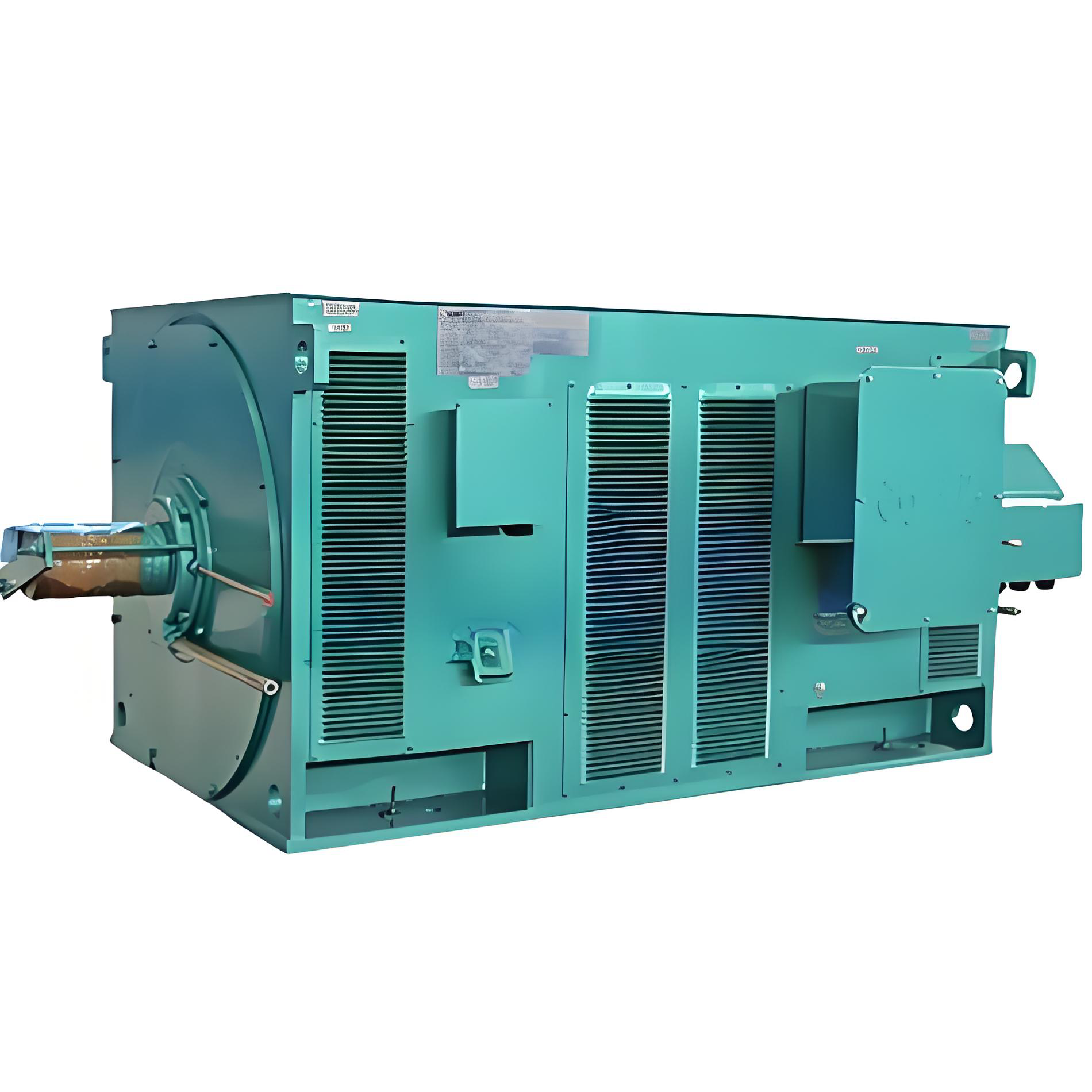

Simo Motor Y Series IP23 Low-Voltage Three-Phase Asynchronous Motor – Complete Technical Guide

Reliable Industrial Power Transmission with High Protection and Stable Performance

The Y Series IP23 Low-Voltage Three-Phase Asynchronous Motor is designed for general industrial applications, combining robust protection, high efficiency, and long-term operational reliability. It is widely used across heavy industry, general manufacturing, and specialized industrial equipment.

1. Product Overview and Technical Features

Product Introduction

- Standard Design: Energy-efficient motor series designed in accordance with national standards.

- Rotor Structure: Squirrel-cage type for durability and smooth operation.

- Rated Voltage/Frequency: 380 V / 50 Hz.

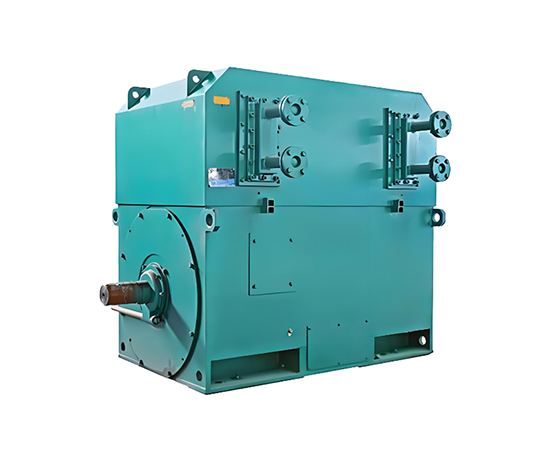

- Power Range: 5.5 kW – 132 kW (some models extend to 220 kW – 280 kW), 14 power levels, 6 frame sizes, 45 specifications.

- Protection Level: IP23 – prevents contact with live parts and intrusion of solid objects >12 mm; drip-proof design at ≤60° vertical angle.

Core Technical Advantages

- High Electrical Efficiency: B-class insulation, Δ-wound stator, IC01 self-cooling. Compliant with IEC standards for installation and maintenance.

- Excellent Starting Performance: High starting torque enables heavy-load startup without excessive current draw.

- Robust Mechanical Design: Optimized structure withstands mechanical and thermal stress for long-term stability.

2. Technical Specifications

| Parameter | Specification / Performance |

|---|---|

| Frame Size Range | H160 – H355 |

| Rated Power | 5.5 kW – 132 kW (extended 220–280 kW) |

| Rated Voltage | 380 V |

| Rated Frequency | 50 Hz |

| Poles | 2, 4, 6 (synchronous speeds: 3000, 1500, 1000 r/min) |

| Protection Level | IP23 (prevents hand contact and solids >12 mm) |

| Insulation Class | B |

| Cooling Method | IC01 (self-cooling) |

| Duty | S1 (continuous) |

| Mounting Form | IMB3, IMB5, IMB35 (standard IEC mounting) |

Performance Highlights:

- High Efficiency: Significant energy savings compared to traditional J02 series.

- Low Vibration & Noise: Precision manufacturing and optimized design reduce operational vibration and noise.

- Wide Voltage Adaptability: Stable performance under grid fluctuations.

3. Structural Design and Configuration

Motor Body

- Protective Housing: IP23 structure allows heat dissipation, prevents solid intrusion and contact with live components.

- Stator: B-class insulation, impregnated winding for high electrical and mechanical strength.

- Rotor: High-quality squirrel-cage rotor ensures smooth, reliable operation.

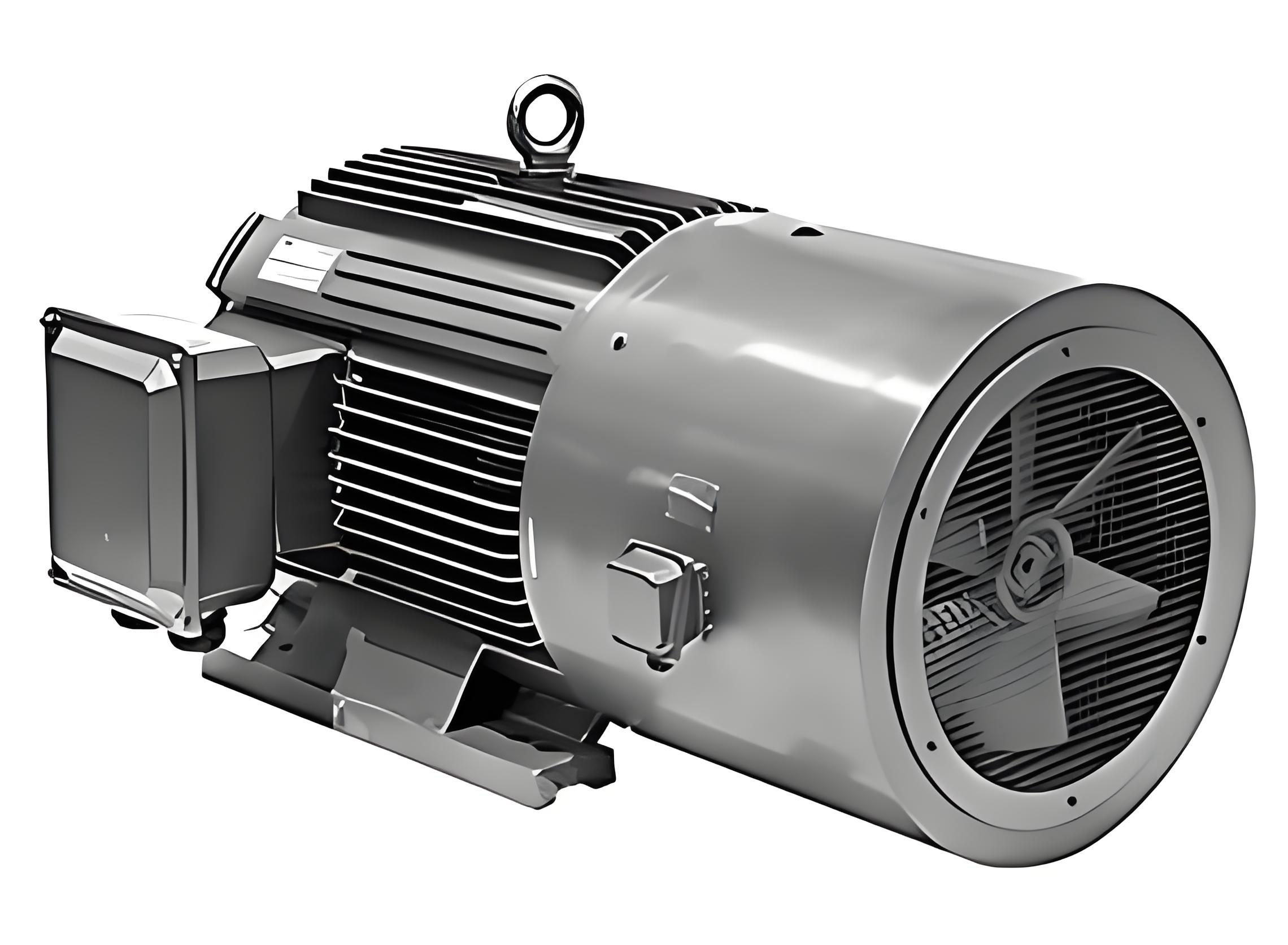

Cooling System

- IC01 Self-Cooling: Internal fan circulates air to dissipate heat effectively, ensuring stable operation under rated load.

- Simple & Reliable Maintenance: Easy-to-service fan and airflow path.

4. Applications & Industrial Scenarios

Heavy Industry

- Mining: Drives crushers, hoists, and lifting equipment under harsh conditions.

- Metallurgy: Powers rolling mills, compressors, and other heavy equipment.

- Power Plants: Drives auxiliary equipment such as fans and pumps.

General Industrial Applications

- Compressors & Pumps: Efficient power for continuous operation.

- Conveyor & Material Handling: Reliable torque and speed control.

- Machine Tools: Stable drive for cutting and machining processes.

Special Scenarios

- Environments requiring effective heat dissipation

- Relatively clean industrial settings

- Equipment needing periodic maintenance access

5. Product Advantages & Value

Operational Reliability

- Robust Design: Mechanical and thermal stress resistant structure.

- High-Quality Insulation: B-class insulation for long service life.

- Environmental Adaptability: Continuous operation at ≤1000 m altitude and ≤40°C ambient temperature.

Energy Efficiency & Economic Benefits

- Reduced Operating Cost: High efficiency lowers energy consumption.

- Optimized Energy Utilization: High power factor and reduced electrical losses.

- Low Lifecycle Cost: Durable design minimizes maintenance and replacement costs.

Maintenance Convenience

- Easy Maintenance: IP23 structure allows quick inspection and servicing.

- Modular Components: Simplifies spare part replacement.

- Long Service Life: Durable insulation reduces maintenance frequency.

6. Installation & Usage Guidelines

Installation Environment

- Suitable for altitudes ≤1000 m and ambient temperatures ≤40°C.

- Relative humidity within standard industrial limits.

- Ensure sufficient space for cooling, ventilation, and maintenance.

Installation & Commissioning

- Foundation: Level, rigid base to support motor weight and operational stress.

- Alignment: Precision alignment with driven equipment via couplings.

- Electrical Connection: Follow motor nameplate and wiring diagrams; ensure proper grounding.

7. Service & Technical Support

Quality Assurance

- Standards Compliance: JB/T 5271-2010 and other national/industry standards.

- Strict Testing Procedures: Each motor undergoes comprehensive performance testing.

- Reliable Output: Ensures high-quality and consistent operation.

After-Sales Support

- Technical Assistance: Guidance on selection, installation, and operation.

- Rapid Response: Timely service to address customer issues.

- Continuous Support: Long-term technical assistance and service guarantees.

The Y Series IP23 Low-Voltage Three-Phase Asynchronous Motor combines reliable protection, energy efficiency, and operational stability, making it an ideal solution for industrial power transmission. Simo Motor ensures each unit delivers safe, stable, and high-efficiency power even in challenging industrial environments.

Choosing the Y Series IP23 motor means selecting reliable performance and professional technical support for long-term industrial applications.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206