Excerpt:

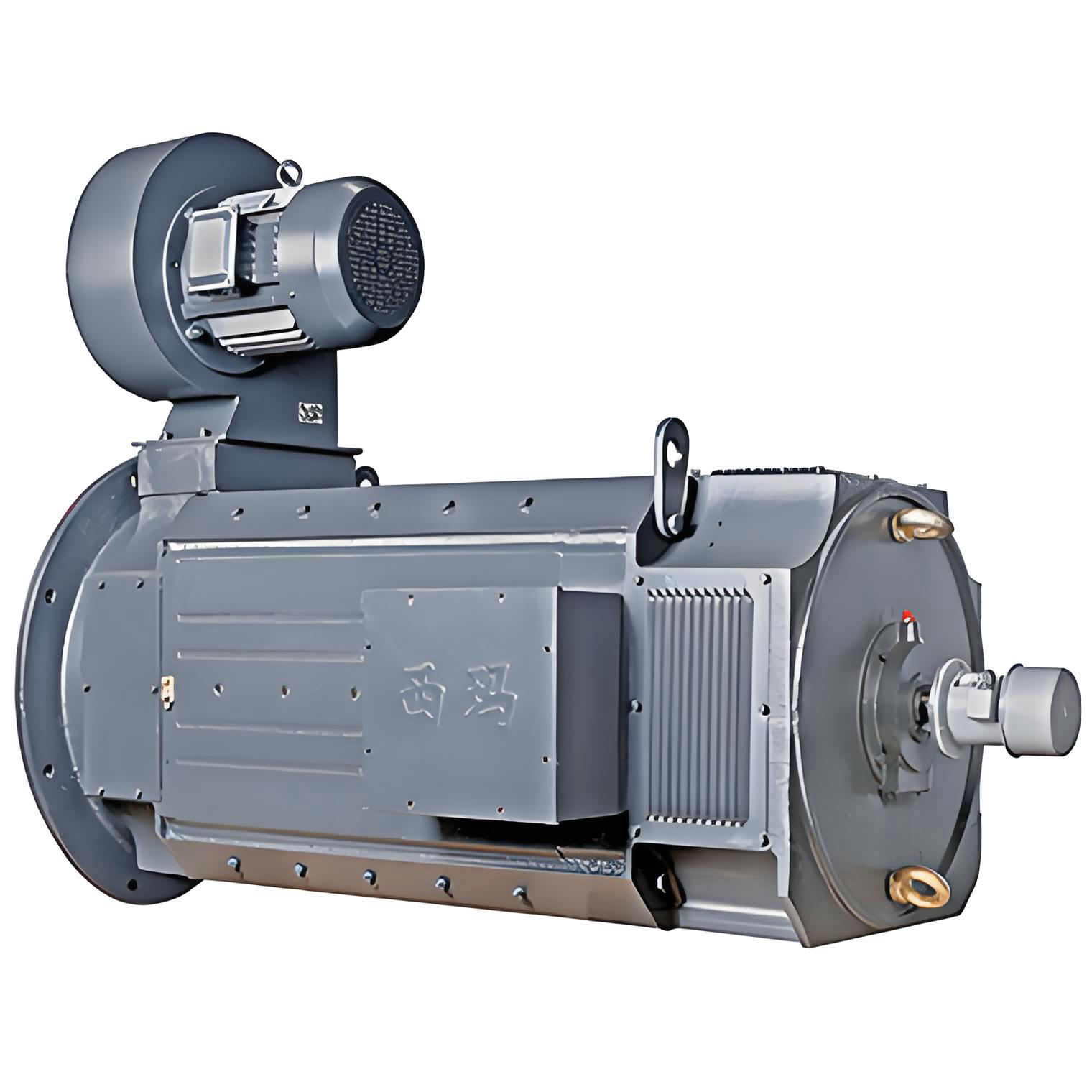

The YR IP23 series low voltage asynchronous motor is designed for stable and reliable operation in indoor industrial environments. With IP23 protection and strong starting torque, it is suitable for applications such as fans, pumps, compressors, and other equipment requiring smooth starting and continuous operation.

YR IP23 Series Low-Voltage Three-Phase Asynchronous Motor: Efficient and Reliable Industrial Power Solution

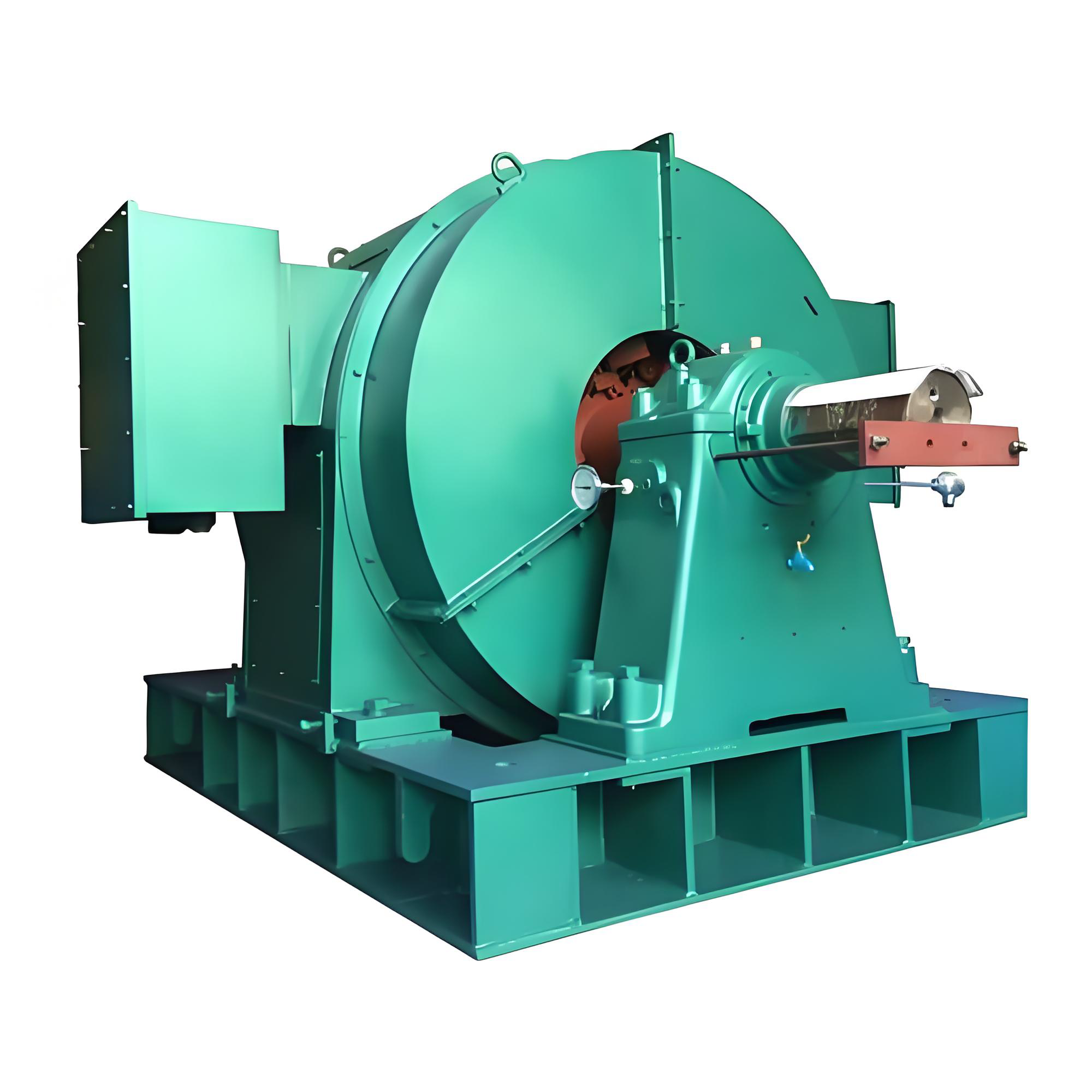

In the field of industrial power transmission, the YR IP23 Series Low-Voltage Three-Phase Asynchronous Motor stands out for its excellent starting performance and flexible speed control. It is an ideal power solution for the startup and continuous operation of heavy-duty machinery across various industries.

The YR IP23 Series Low-Voltage Three-Phase Asynchronous Motor is a partially enclosed wound-rotor three-phase motor, engineered with advanced electromagnetic design and high-quality materials. It delivers high starting torque, adjustable speed capabilities, reliable operation, and easy maintenance. This motor series is suitable for heavy industrial applications where both robust performance and flexible control are required, including compressors, crushers, hoists, fans, pumps, and conveyor systems.

The IP23 enclosure ensures protection against solid objects larger than 12 mm and prevents vertical water dripping, making it suitable for standard industrial environments. With rated voltages typically at 380V and frequencies at 50Hz, and power ranges covering 4 kW to 250 kW, the YR IP23 Series can accommodate a wide range of industrial applications.

Key Technical Features:

- Superior Starting Performance: The wound-rotor design provides high starting torque with reduced inrush current, minimizing impact on the electrical supply system.

- Flexible Speed Control: External rotor resistors allow smooth speed adjustment for different operational requirements, offering greater flexibility than standard squirrel-cage motors.

- Reliable Operation: Equipped with B or F class insulation, low vibration, low noise, and high mechanical strength, ensuring long-term, stable performance.

- High Efficiency: Optimized electrical and magnetic design improves efficiency, reduces energy consumption, and lowers operational costs.

Applications:

- Heavy Industry: Mining equipment, metal processing machinery, power plant auxiliaries.

- General Industrial Equipment: Compressors, pumps, conveyor systems, machine tools.

- Special Conditions: Applications requiring high starting torque, frequent starts, or minor speed adjustments.

Advantages and Value:

- Durable Construction: Robust wound-rotor and partially enclosed design for long-term reliability.

- Energy-Saving: Reduced starting current and optimized efficiency lower operating costs.

- Maintenance-Friendly: Modular design and accessible components simplify servicing and inspections.

- Versatile Performance: Suitable for a wide range of industrial machinery and heavy-duty applications.

The YR IP23 Series Low-Voltage Three-Phase Asynchronous Motor provides an efficient, reliable, and cost-effective industrial power solution. With advanced technology, flexible operation, and professional support from Xi’an Simo Motor, this motor series ensures stable and efficient performance in demanding industrial environments.

YR IP23 Series Low-Voltage Three-Phase Asynchronous Motor: Efficient and Reliable Industrial Power Solution

1. Product Overview and Technical Features

Product Introduction

The YR IP23 Series is a wound-rotor three-phase asynchronous motor specifically designed for industrial power transmission. Featuring a partially enclosed IP23 protective structure, this motor operates at a rated voltage of 380V and a frequency of 50Hz. The power range spans from 4kW to 132kW (with certain models extending up to 355kW), covering frame sizes from H160 to H400, to meet diverse industrial application needs.

As a core industrial power source, the YR IP23 Series is ideal for driving heavy-duty machinery such as compressors, crushers, hoists, fans, pumps, and conveyor belts. Its protective structure ensures reliable operation in a variety of industrial environments, making it suitable for mining, mechanical manufacturing, petrochemical, power generation, and other industrial enterprises.

Core Technical Features

- Superior Starting Performance: The wound-rotor design delivers high starting torque at low inrush current, reducing impact on the power grid and outperforming standard squirrel-cage motors for heavy-load startups.

- Flexible Speed Control: Rotor external resistors allow smooth speed adjustment within a range, fulfilling various operational requirements.

- High Electrical Efficiency: The motor exhibits high efficiency, low noise, reliable operation, and excellent energy-saving performance.

2. Technical Specifications and Performance

The YR IP23 Series covers a wide range of specifications to meet industrial power requirements.

Key Technical Parameters:

| Parameter | Specification |

|---|---|

| Frame Size | H160–H400 |

| Rated Power | 4kW–355kW (varies by model) |

| Rated Voltage | 380V |

| Rated Frequency | 50Hz |

| Poles | 4, 6, 8 (synchronous speeds 1500, 1000, 750 r/min) |

| Protection | IP23 (prevents contact with live parts and ingress of solid objects >12mm) |

| Insulation | Class B |

| Cooling | IC01 (self-ventilated fan cooling) |

| Duty | S1 (continuous duty) |

| Installation | IMB3 (foot-mounted, horizontal) |

Performance Highlights:

- High Starting Torque: Provides powerful startup for heavy machinery, overcoming limitations of insufficient supply capacity for squirrel-cage motors.

- Adjustable Speed: External rotor resistors enable smooth speed variation for process flexibility.

- Low Vibration & Noise: Optimized design and precise manufacturing ensure stable operation.

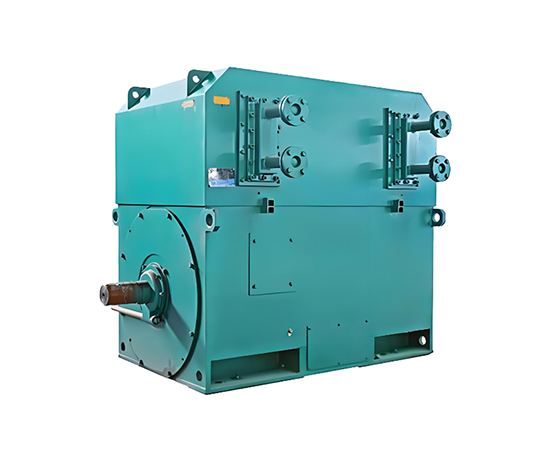

3. Structural Design and Configuration

Motor Body Structure:

- Protective Housing: IP23-rated enclosure prevents access to live or moving parts and solid objects >12mm, with superior drip protection compared to conventional designs.

- Stator Design: Class B insulation; options include flat copper formed windings or round copper windings. Windings are secured and varnished for mechanical and electrical strength.

- Rotor Design: Wound-rotor structure with slip rings connected to external resistors; precision manufacturing ensures smooth and reliable operation.

Wiring and Cooling System:

- Terminal Box: Six terminals for H280 or three terminals for H315–H335; △ connection method for easy wiring.

- Cooling: IC01 self-ventilated fan system circulates air to remove heat efficiently, ensuring continuous operation at rated load.

4. Application Areas

Heavy Industry:

- Mining: Drives crushers, hoists, and elevators under harsh conditions.

- Metallurgy: Powers rolling mills, compressors, and related equipment.

- Power Generation: Suitable for fans, pumps, and auxiliary equipment in power plants.

General Industrial Equipment:

- Compressors & Pumps: Reliable solution for continuous operation.

- Conveyors: Drives belts and material handling systems.

- Machine Tools: Provides stable power output for various machining equipment.

Special Applications:

- High starting torque requirements.

- Limited supply capacity lines.

- Frequent or prolonged starts.

- Small-range speed adjustment.

- Synchronization for “electric shaft” or specialized processes.

5. Product Advantages and Value

Operational Reliability:

- Robust IP23 construction resists mechanical and thermal stress.

- High-quality B-class insulation ensures long life.

- Suitable for continuous operation up to 1000m altitude and -15°C to +40°C ambient temperature.

Energy and Economic Benefits:

- Lower starting current reduces power grid load.

- High starting torque ensures smooth operation of heavy equipment.

- Long service life and low maintenance reduce total lifecycle costs.

- Compact and lightweight design (average 15% smaller, 12% lighter than traditional motors).

Maintenance Convenience:

- IP23 design facilitates easy inspection and servicing.

- Modular components simplify replacement and spare parts management.

- Long-life insulation reduces maintenance frequency.

6. Installation and Operation Guidelines

Installation Environment:

- Suitable for industrial environments without flammable, explosive, or corrosive gases.

- Ambient conditions: altitude ≤1000m, temperature -15°C to +40°C, relative humidity ≤90%.

- Ensure adequate space for ventilation and maintenance.

Installation and Commissioning:

- Pre-insert starting resistors in rotor circuit; direct rotor short-circuit start prohibited.

- Transmission: coupling, spur gear, or pulley drive supported.

- Electrical connection: follow nameplate and wiring diagram; ensure proper grounding.

7. Service and Technical Support

Quality Assurance:

- Compliant with JB/T 5269-2018 and other national and industry standards.

- Rigorous manufacturing and testing procedures ensure consistent performance.

- Each motor undergoes full factory performance testing.

After-Sales Service:

- Professional technical consultation for motor selection and installation guidance.

- Rapid response to service requests.

- Long-term technical support and maintenance services.

YR IP23 Series Low-Voltage Three-Phase Asynchronous Motors combine exceptional starting performance, flexible speed control, and reliable operation. Through continuous innovation and strict quality management, each motor delivers safe, stable, and efficient power in demanding industrial environments.

Choosing YR IP23 Series Motors means selecting dependable performance and comprehensive technical support, driving energy-efficient progress in industrial applications worldwide.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206