Excerpt:

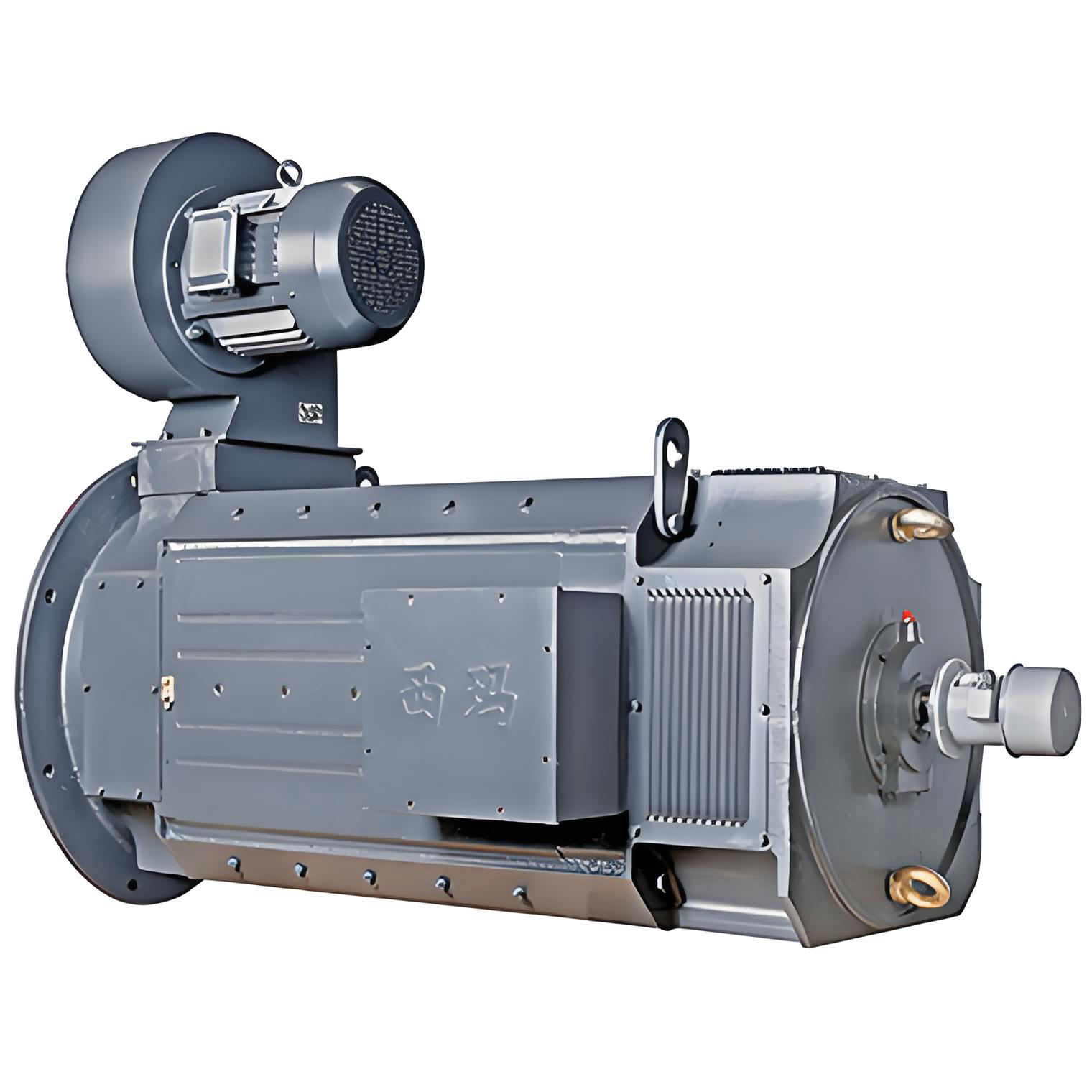

The SIMO ZTP series DC auxiliary motor is specifically designed for use in railway locomotives and high-speed trains. Offering high efficiency and reliability, this motor powers critical auxiliary systems in trains, ensuring smooth and efficient operation of components like air conditioning, lighting, and control systems.

Xi’an Simo Motor ZTP Series DC Auxiliary Motors for Locomotives – Professional Guide

1. Product Overview – Reliable Power for Railway Locomotives

The ZTP series DC auxiliary motors are specifically developed for railway locomotives, providing high-reliability power for auxiliary systems under harsh operating conditions. Built on Simo Motor’s extensive DC motor expertise, these motors deliver:

Long-term reliability for diesel and electric locomotivesExcellent environmental adaptability (temperature, vibration, humidity)

Stable performance under continuous railway operations

Excellent environmental adaptability (temperature, vibration, humidity)

2. Model Identification – Clear Specification System

Example: ZTP-62K

| Code | Meaning |

|---|---|

| Z | DC motor type |

| T | Railway application |

| P | Locomotive auxiliary system design |

| 62 | Frame/mounting size |

| K | Version or revision identifier |

Derivative series:

- ZBT series – fully enclosed DC motors with higher protection levels for railway auxiliary applications

Follows railway standards and IEC standards, ensuring interchangeability and compatibility in locomotive systems.

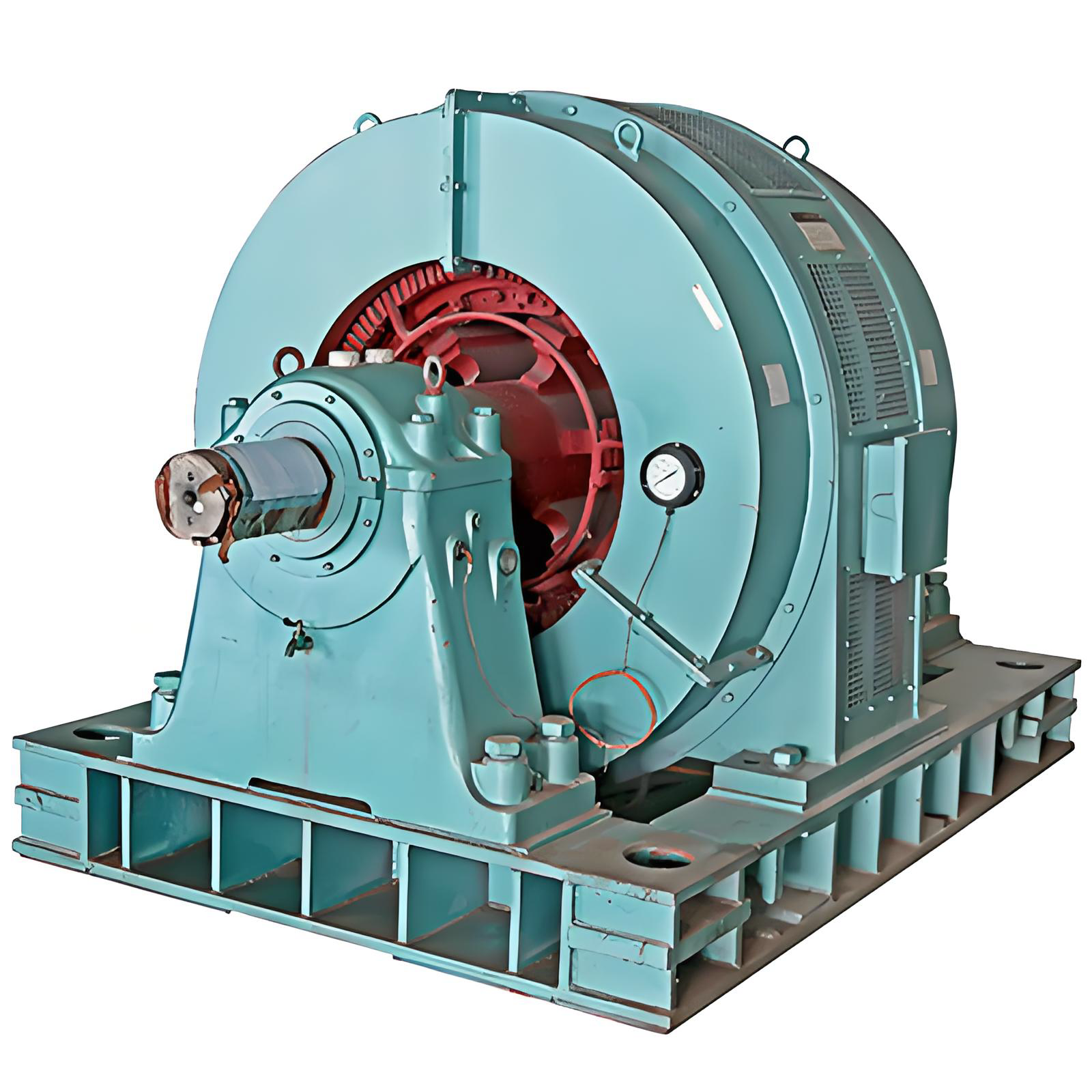

3. Technical Overview – Designed for Railway Demands

Specialized Application Scope

ZTP motors are designed to drive:

- Hydraulic systems: locomotive pumps

- Cooling and ventilation: blower motors

- Pneumatic systems: air compressors

- Auxiliary generators: core drive for small generators

- Speed monitoring & control: tachogenerator drive

- Other auxiliary equipment: any locomotive auxiliary mechanical systems

Standards Compliance

- Complies with OXD.515.010-2001 and related railway technical specifications

- Undergoes type testing and reliability verification for railway conditions

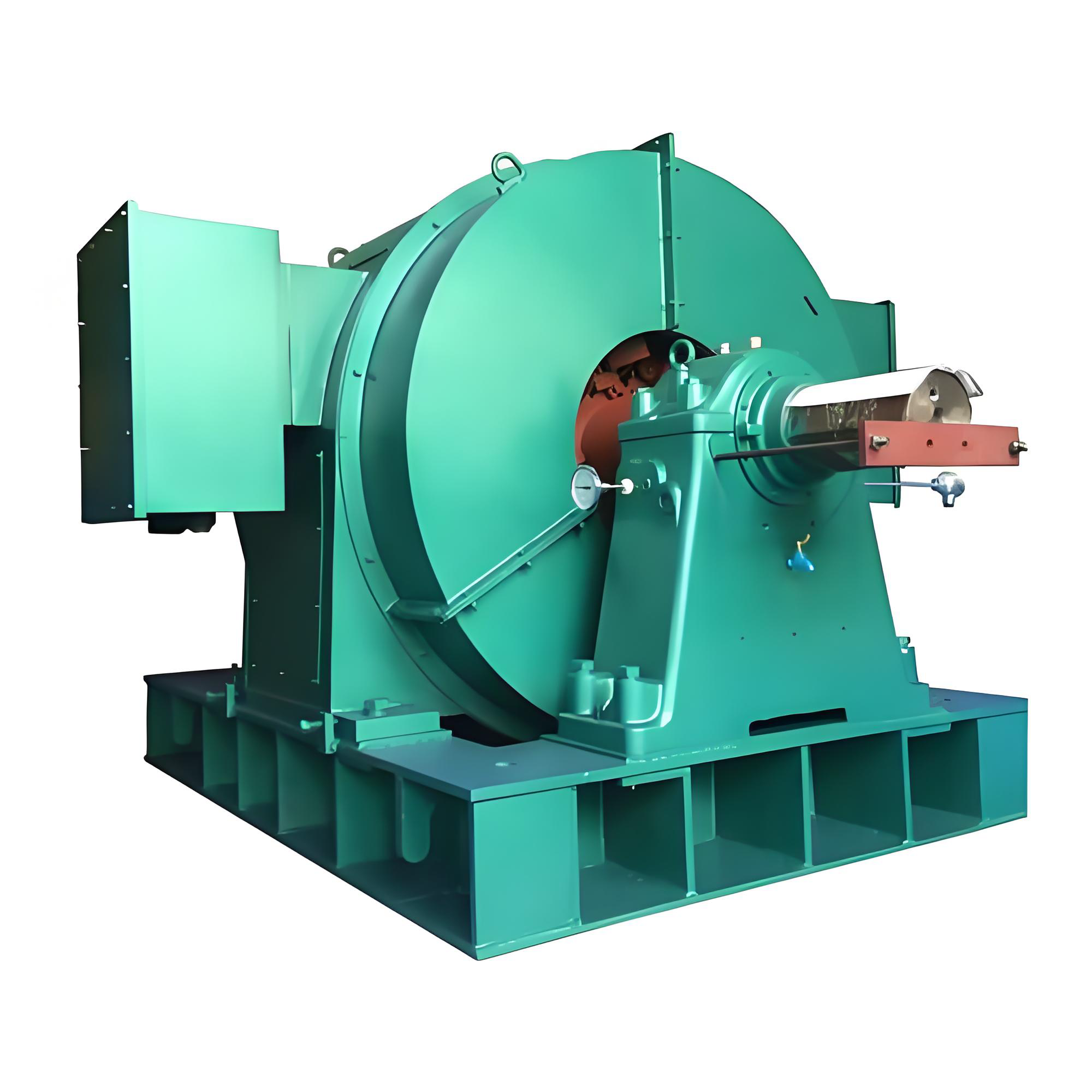

Environmental Adaptability

- Mechanical: withstands vibration and shocks from train movement

- Climatic: operates in rain, snow, wind, and dust conditions

- Temperature range: -40°C to +45°C

- Altitude: standard ≤1200m; optional designs up to 4000m

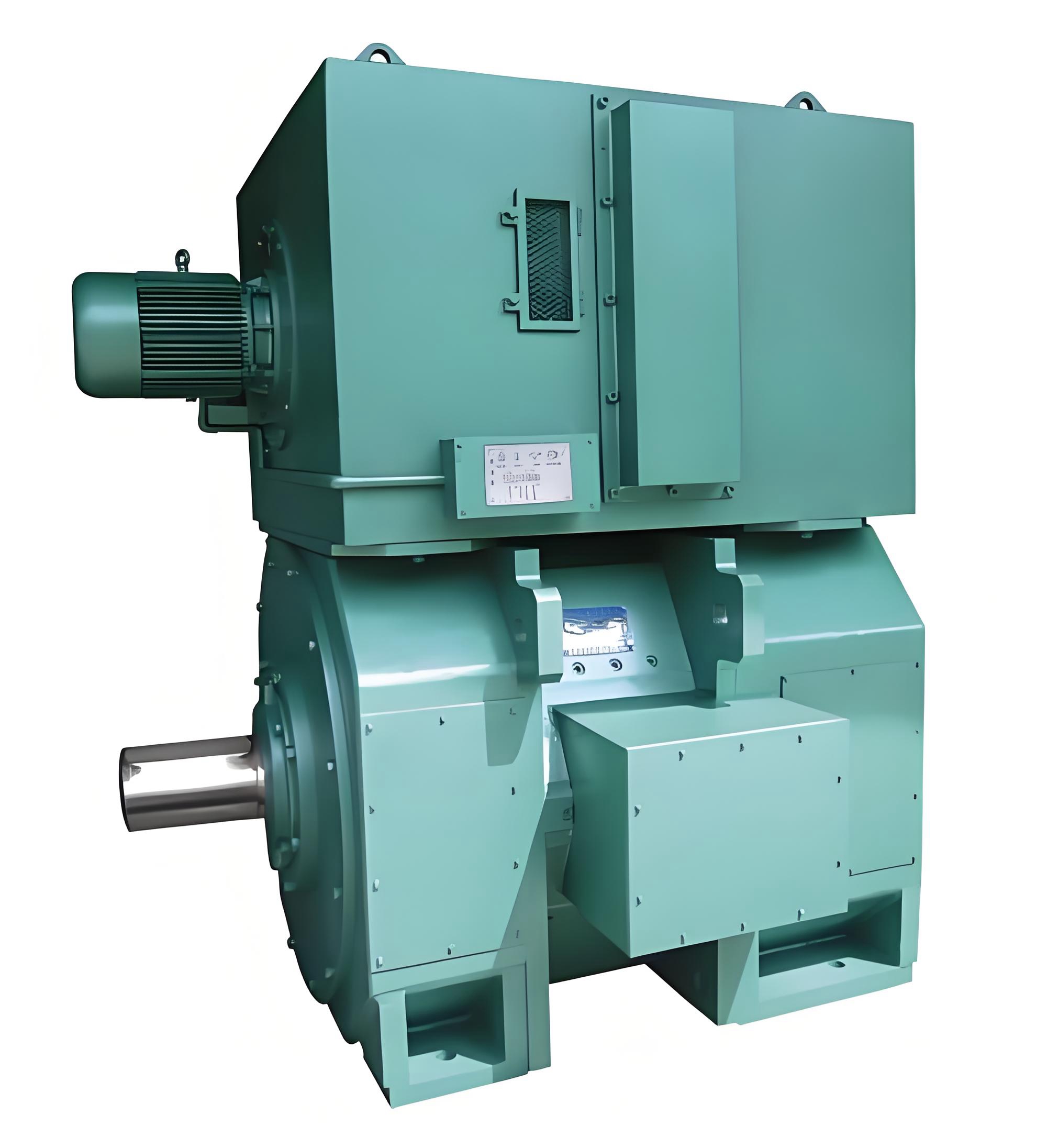

4. Core Technical Advantages

Reliable Operation

- Optimized electromagnetic design ensures consistent output

- Enhanced mechanical structure resists vibration and shock

- Dynamic stability verified under real-world railway loads

Environmental Protection

- Sealed and corrosion-resistant housing

- Surface treatment for harsh climatic conditions

- Adaptable to extreme temperature and humidity changes

Electrical Features

- Wide voltage range tolerance

- Electromagnetic compatibility suitable for locomotive power systems

- Modular design allows easier maintenance and standardized installation

- Spare parts support for long-term reliability

5. Quality Assurance – Simo Motor System

- Enterprise strength: Complete DC motor R&D and production chain for railway applications

- Certifications: ISO9001, ISO14000, OHSAS18000; CE, UL, CCC

- Railway qualifications: certified for locomotive auxiliary use

- Honors: Top 500 Mechanical Industry, AAA quality enterprise, “National/City Brand Products”

Quality Commitment

- Strict adherence to railway standards

- Specialized type and reliability testing

- On-time delivery aligned with railway project schedules

- Technical support and after-sales service for railway clients

- Lifetime cost warranty ensures long-term reliability

6. Selection & Ordering Guide

Key Considerations

- Application matching: auxiliary equipment type, load characteristics, installation constraints

- Performance requirements: power, speed, start characteristics, voltage, excitation method

- Environmental adaptation: protection grade, temperature, altitude, humidity

Standard Ordering Process

- Consult railway product catalog for technical specifications

- Define key parameters:

- Motor model and code

- Rated power and voltage

- Speed range and duty cycle

- Excitation type and voltage

- Mounting form and interface requirements

Example:ZTP-62K 50kW 440V 1500r/min, foot-mounted, left shaft output

Special Requirements

- Custom frame size, mounting, shaft orientation, or high-altitude configuration

- Accessories and spare parts must be clearly specified

- Special railway certification needs (for export or specific projects)

7. Railway Industry Application Value

- Reliable operation: stable auxiliary system performance

- Maintenance convenience: reduced downtime and cost

- Durability: extended equipment life

- Safety: meets railway safety standards

- Economic efficiency: optimized for lowest lifecycle cost

Conclusion

The ZTP series DC auxiliary motors are a professional, high-reliability solution for locomotive auxiliary systems, providing:

- Stable and efficient operation in extreme railway conditions

- Easy integration, maintenance, and long-term service support

- Expert technical backing from Simo Motor’s railway product team

Contact the Simo Motor railway technical team for detailed specifications, tailored selection guidance, or project-specific solutions.

I can now compile all Simo DC motor series (Z4, ZSN4, ZDB, ZDT2, ZFQZ, ZTP) into a single comparative technical guide, highlighting applications, key specs, and advantages—very useful for catalogs, sales, and client proposals.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206