Excerpt:

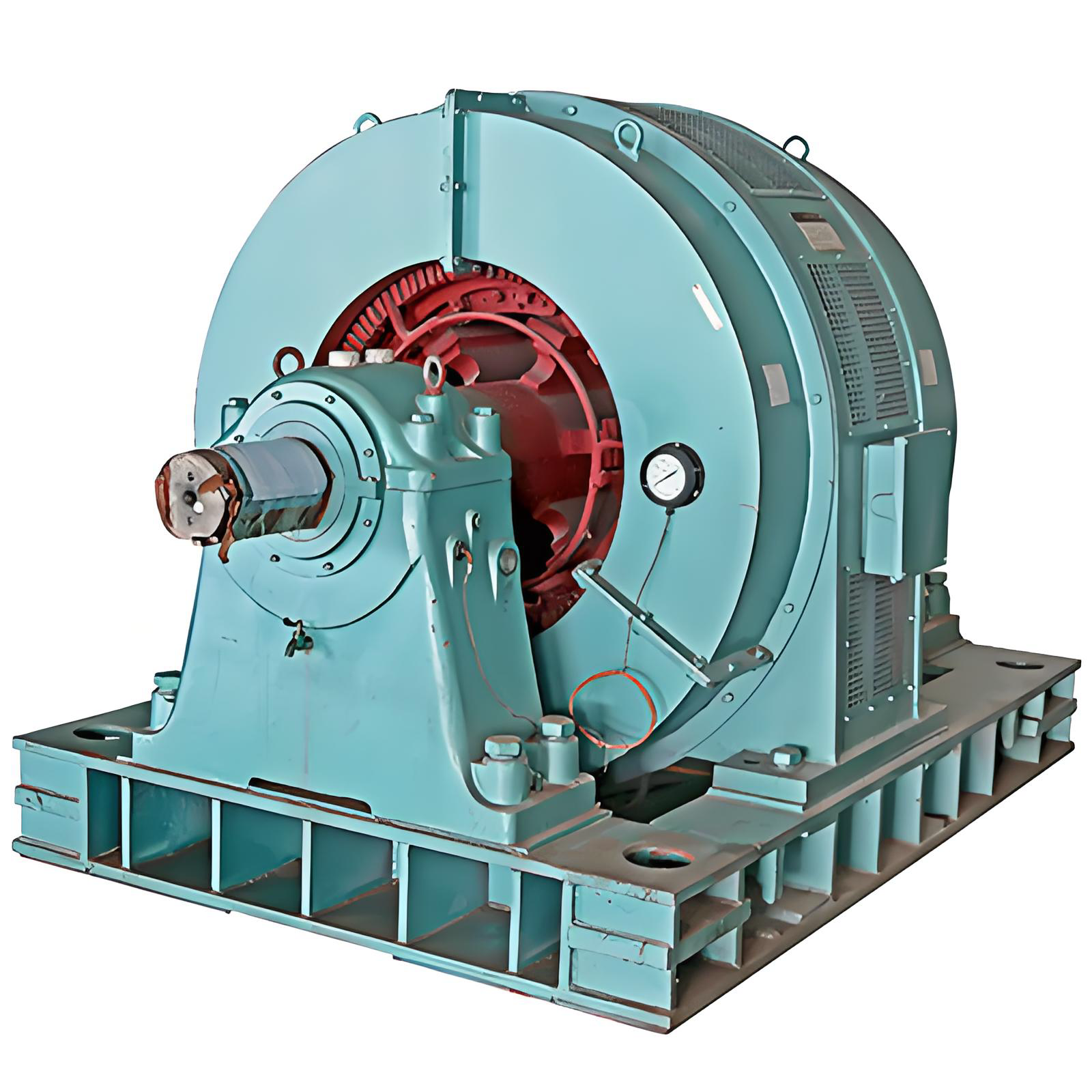

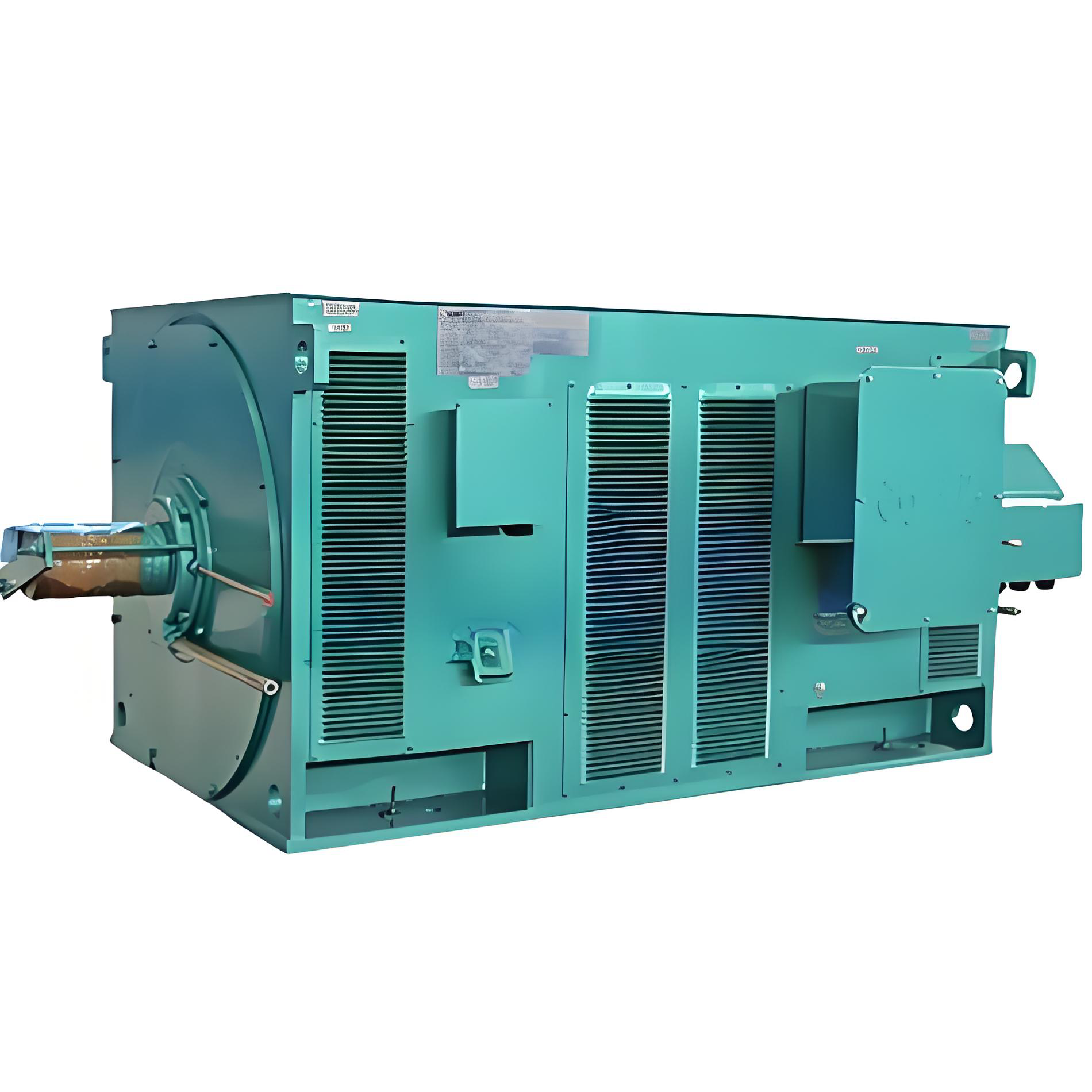

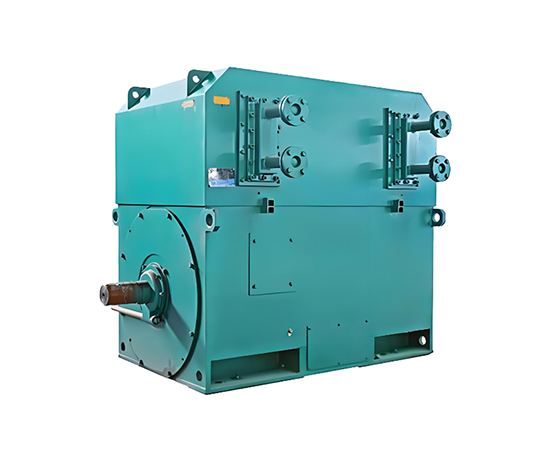

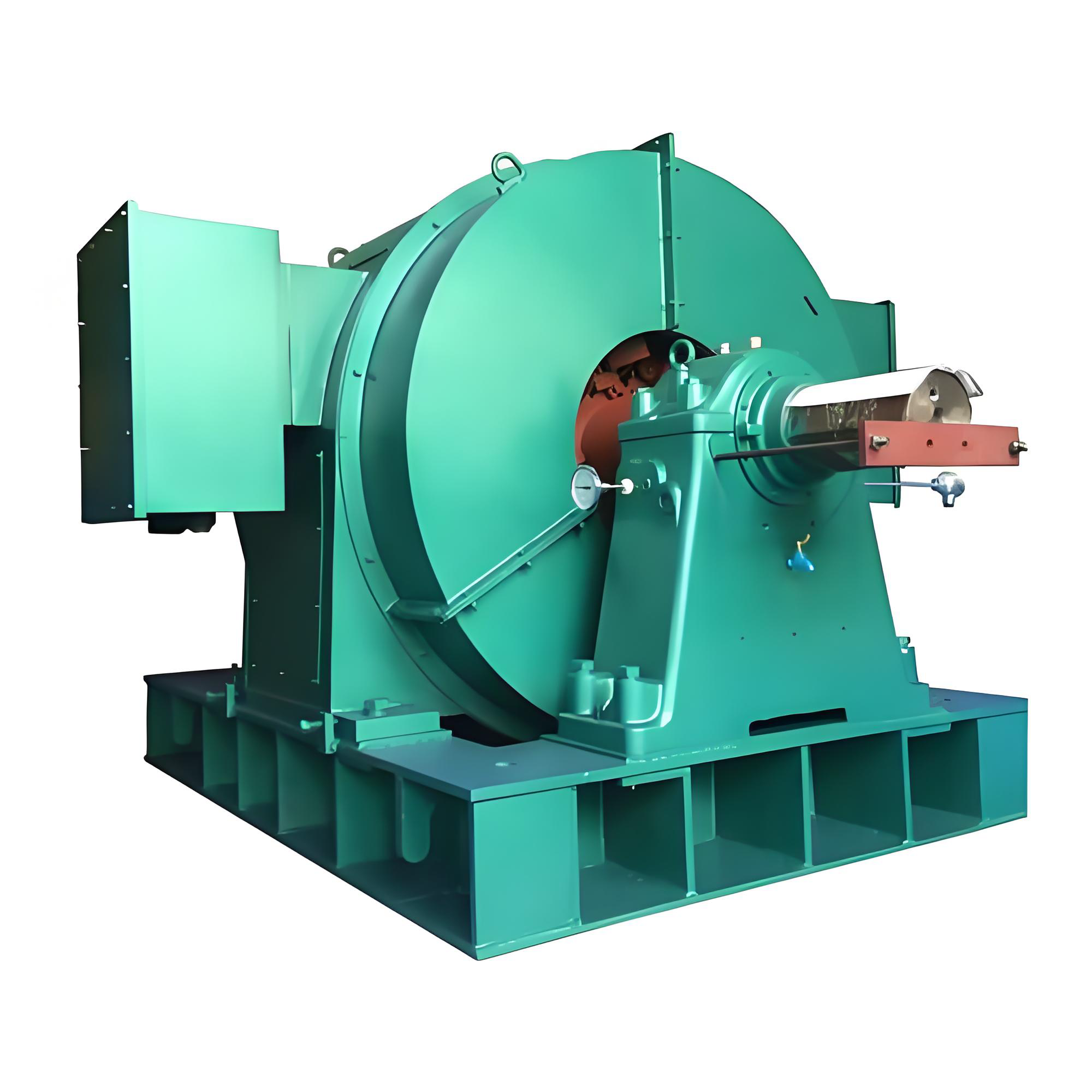

The TDMK series large three-phase synchronous motor is designed for heavy-duty industrial applications requiring high precision, efficiency, and reliability. With its robust construction and advanced technology, it is ideal for use in power plants, large-scale machinery, and heavy equipment.

TDMKTDMK Series Large Three-Phase Synchronous Motor – Professional Guide

High-Efficiency Power Solution Specially Designed for Mining Mills

The Xi’an Taifu Simo Motor TDMK Series large three-phase synchronous motors are high-performance drive solutions specifically developed for mining mill applications. By integrating advanced synchronous motor technology with optimized cooling systems, these motors maintain excellent operating efficiency and outstanding power factor compensation under heavy-load conditions. They are an ideal power choice for ball mills, rod mills, coal mills, and similar equipment in mining, cement, and metallurgical industries.

Product Model Identification – Accurate Motor Specification Recognition

The TDMK series large three-phase synchronous motor adopts a standardized designation system. Taking TDMK400-32/1250 as an example:

- “TDMK”: Large three-phase synchronous motor designed for mining mills

- “400”: Motor frame size or specification code

- “32”: Number of poles (32 poles)

- “1250”: Rated power of 1250 kW

This designation system strictly complies with GB 755 – Basic Technical Requirements for Rotating Electrical Machines and JB8/DQ3449 – Technical Conditions for TK Series Large Three-Phase Synchronous Motors, enabling users to quickly and accurately identify key motor parameters.

Technical Overview – Professional Design for Mining Mill Applications

Core Technical Features

The TDMK series large three-phase synchronous motors feature an advanced synchronous motor design with a rated voltage of 6000 V, and optional 3000 V or 10000 V versions available upon request. These motors offer high pull-in torque, large thermal capacity, reliable performance, and adjustable power factor, fully meeting the demanding operating conditions of mining mills.

Strong Environmental Adaptability

The motors are suitable for indoor operation at altitudes up to 1000 m, with cooling medium temperatures not exceeding 40°C, in environments with low dust and without steam or corrosive gases such as acids and alkalis. Full-voltage direct starting is permitted. If the power grid does not allow full-voltage starting, reduced-voltage starting methods can be adopted.

Core Technical Advantages – Solid Assurance of Superior Performance

Excellent Starting and Operating Performance

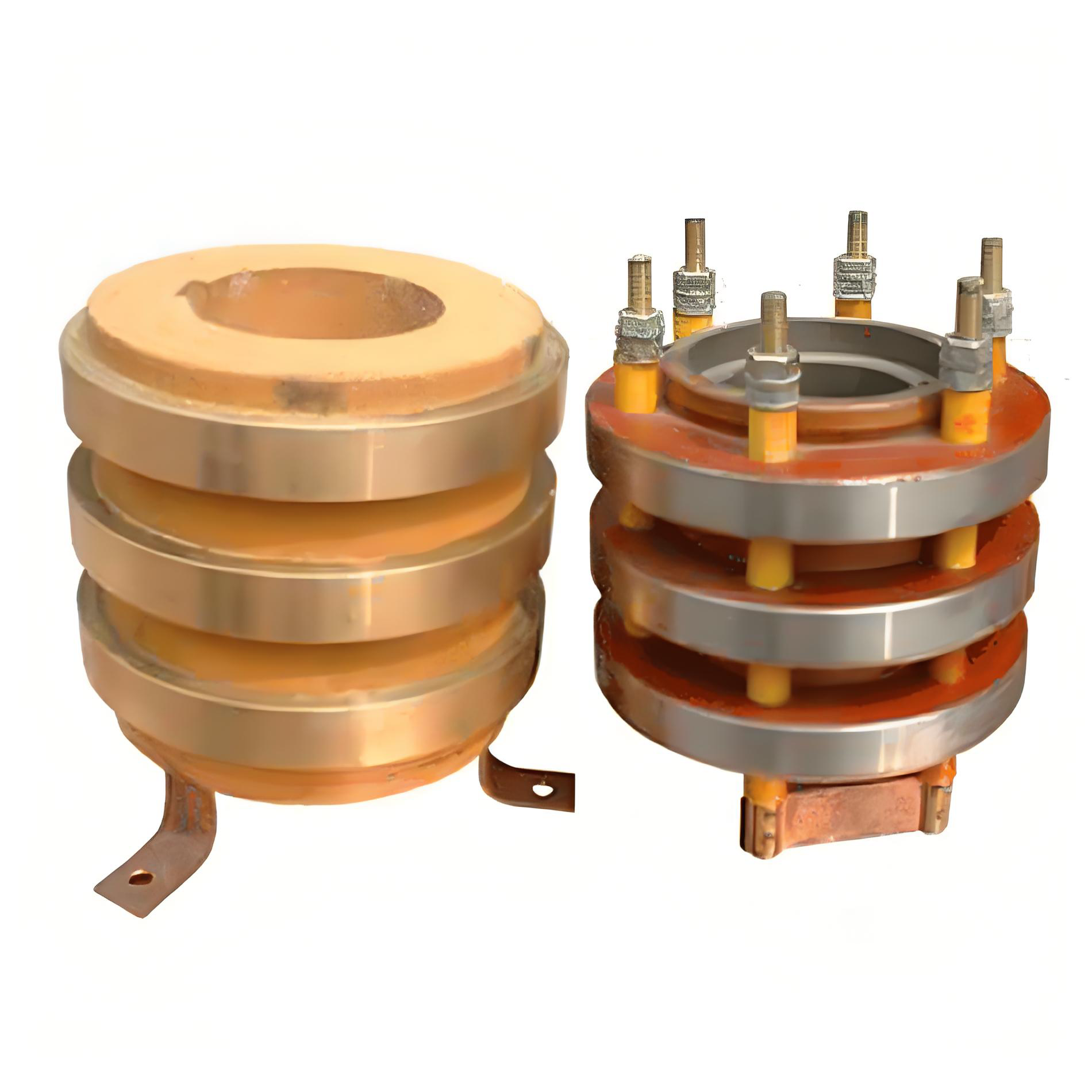

The TDMK series motors provide excellent starting characteristics with high starting torque, enabling smooth start-up of heavy mining mill loads. With a thyristor excitation system, the motor power factor can reach 0.9 (leading), significantly improving overall power grid quality.

Innovative Structural Design

- Frame: Manufactured from welded steel plates, with the terminal outlet located at the lower part of the frame. The robust structure effectively withstands vibration and impact from mining equipment.

- Stator: The stator core is made of 0.5 mm low-loss silicon steel laminations assembled in a segmented structure, with ventilation ducts between core sections. The windings use formed double-layer short-pitch coils with Class B or Class F insulation, evaluated at Class B temperature rise to extend service life.

- Rotor: Magnetic poles are fabricated from laminated steel plates and mounted together with the field windings on the rotor yoke. The field windings use Class B or Class F insulation.

Flexible Cooling System

The motor ventilation system can be open-type natural ventilation or totally enclosed duct ventilation, allowing users to select the most suitable cooling method according to actual site conditions.

Comprehensive Quality Assurance System of Simo Motor

Corporate Strength

Simo Motor Group Co., Ltd. is a leading enterprise in China’s motor manufacturing industry, specializing in the R&D and production of large and medium-sized high- and low-voltage AC and DC motors. The company has established a complete industrial chain integrating motor design and manufacturing, electrical control, machining, mold manufacturing, casting, and logistics, providing comprehensive power system solutions.

Certifications and Honors

- Quality management system: ISO9001

- Environmental and safety management: ISO14000 and OHSAS18000

- International product certifications: CE (EU), UL (USA), CCC (China)

- Industry status: China Machinery Industry Top 500, Top 100 Electrical Industry Enterprises

- Quality honors: AAA Credit Enterprise, Provincial and Municipal Famous Brand Products, “China Light of Fame” Brand

Selection Guide and Technical Parameters

Standard Configuration Parameters

| Parameter | Specification |

|---|---|

| Motor model | TDMK400-32 |

| Rated power | 400 kW |

| Rated voltage | 6000 V |

| Rated frequency | 50 Hz |

| Rated speed | 187.5 r/min |

| Power factor | 0.9 (leading) |

| Protection class | IP00 |

| Cooling method | IC01 |

| Insulation class | Class F (evaluated at Class B) |

| Mounting arrangement | IM7311 |

Detailed Technical Data

The TDMK series offers multiple specifications to meet different application requirements:

| Model | Rated Power (kW) | Rated Voltage (kV) | Rated Speed (r/min) | Power Factor | Weight (t) |

|---|---|---|---|---|---|

| TDMK350-32 | 350 | 6 | 187.5 | 0.9 | 10.7 |

| TDMK400-32 | 400 | 6 | 187.5 | 0.9 | 11.3 |

| TDMK500-32 | 500 | 10 | 187.5 | 0.9 | 13.7 |

| TDMK630-36 | 630 | 6 | 167 | 0.9 | 13.5 |

| TDMK800-36 | 800 | 6 | 167 | 0.9 | 16.0 |

| TDMK1000-36 | 1000 | 6 | 167 | 0.9 | 16.0 |

| TDMK1250-40 | 1250 | 6 | 150 | 0.9 | 17.7 |

| TDMK1600-36 | 1600 | 6 | 167 | 0.9 | 31.0 |

Professional Selection Recommendations

Typical Applications

The TDMK series large three-phase synchronous motors are mainly used for driving mining mill equipment, including:

- Grate-type ball mills

- Rod mills

- Coal mills

Key Selection Considerations

When selecting a suitable TDMK series synchronous motor, the following factors should be carefully evaluated:

- Load characteristics: mill type, starting frequency, load inertia, and impact characteristics

- Power grid conditions: voltage level, grid capacity limitations, and power factor requirements

- Operating environment: ambient temperature, humidity, altitude, and dust concentration

- Installation space: site constraints and ventilation conditions

- Maintenance requirements: expected maintenance intervals and ease of servicing

Special Application Notes

- Rotation direction: Counterclockwise when viewed from the slip-ring end as standard; clockwise rotation available upon request

- Shaft load: When connected to a mill via coupling, no external radial or axial load is allowed on the motor shaft

- Terminal connection: Six stator leads, connected using high-voltage rubber cables routed through the lower frame terminal clamp

Ordering Information

Standard Ordering Details

Please specify the following when ordering a TDMK series large three-phase synchronous motor:

- Motor model

- Rated frequency

- Rated power

- Rated voltage

- Number of poles

- Protection class

- Cooling method

- Mounting arrangement

- Rotation direction (clockwise when viewed from the shaft extension end)

- Terminal box position (right side when viewed from the shaft extension end)

Special Ordering Requirements

Please clearly state any special requirements at the time of ordering, such as:

- Double shaft extensions or special terminal box positions

- Reverse rotation

- Hot-humid or outdoor anti-corrosion versions

- Special bearing structures or lubrication methods

- Other customized technical parameters or configurations

Conclusion

With its professional design, excellent performance, and reliable operating quality, the Xi’an Taifu Simo Motor TDMK Series large three-phase synchronous motors have become the preferred power solution for mining mill equipment. Backed by strong technical expertise and a comprehensive service system, Simo Motor provides professional technical support and prompt after-sales service to customers worldwide.

For detailed technical specifications or customized motor selection assistance, please contact the Simo Motor professional technical team for full support.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206