Excerpt:

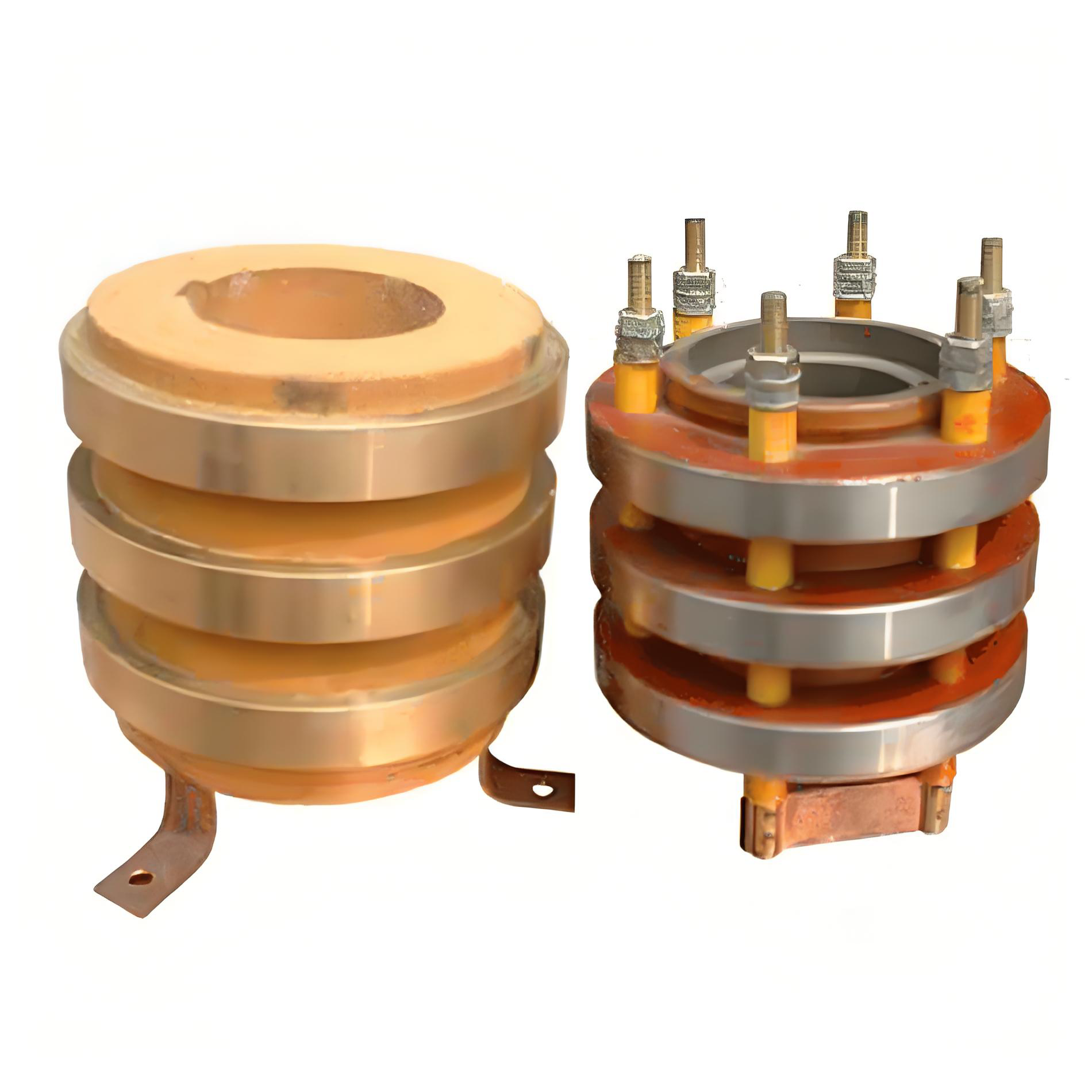

The motor carbon brush is a key component that conducts current between the stationary and rotating parts of a motor. Made from high-quality carbon material, it ensures reliable electrical contact, smooth motor operation, and long-lasting performance.

SIMO Motor Carbon Brushes: Superior Quality and Stable Performance

01 Product Overview

SIMO Motor carbon brushes are precision-engineered critical components manufactured from high-grade electrical carbon materials. Designed for AC and DC motors, generators, and industrial electrical machines, these brushes use a scientifically optimized mix of metal powders and carbon, sintered at high temperatures and precisely machined.

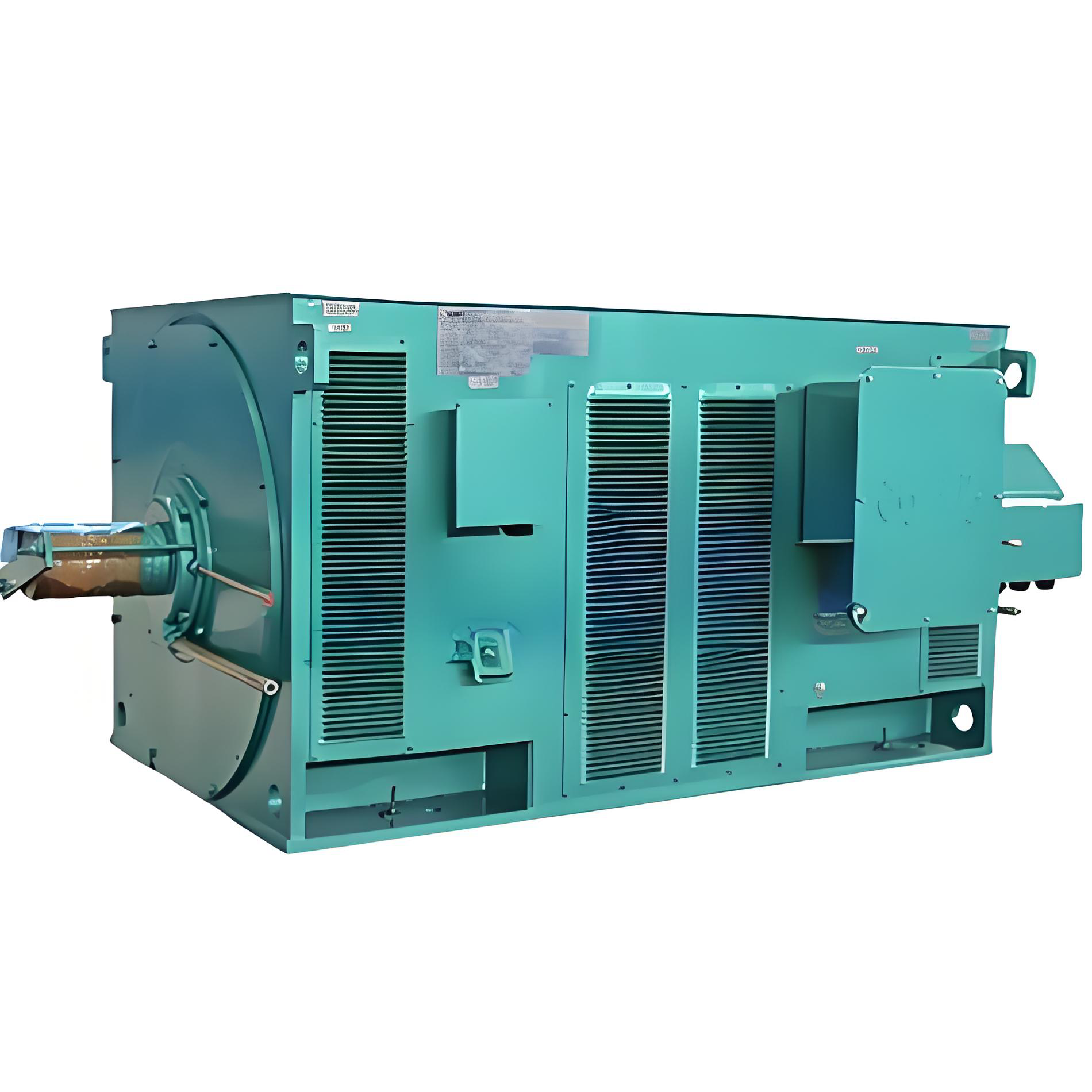

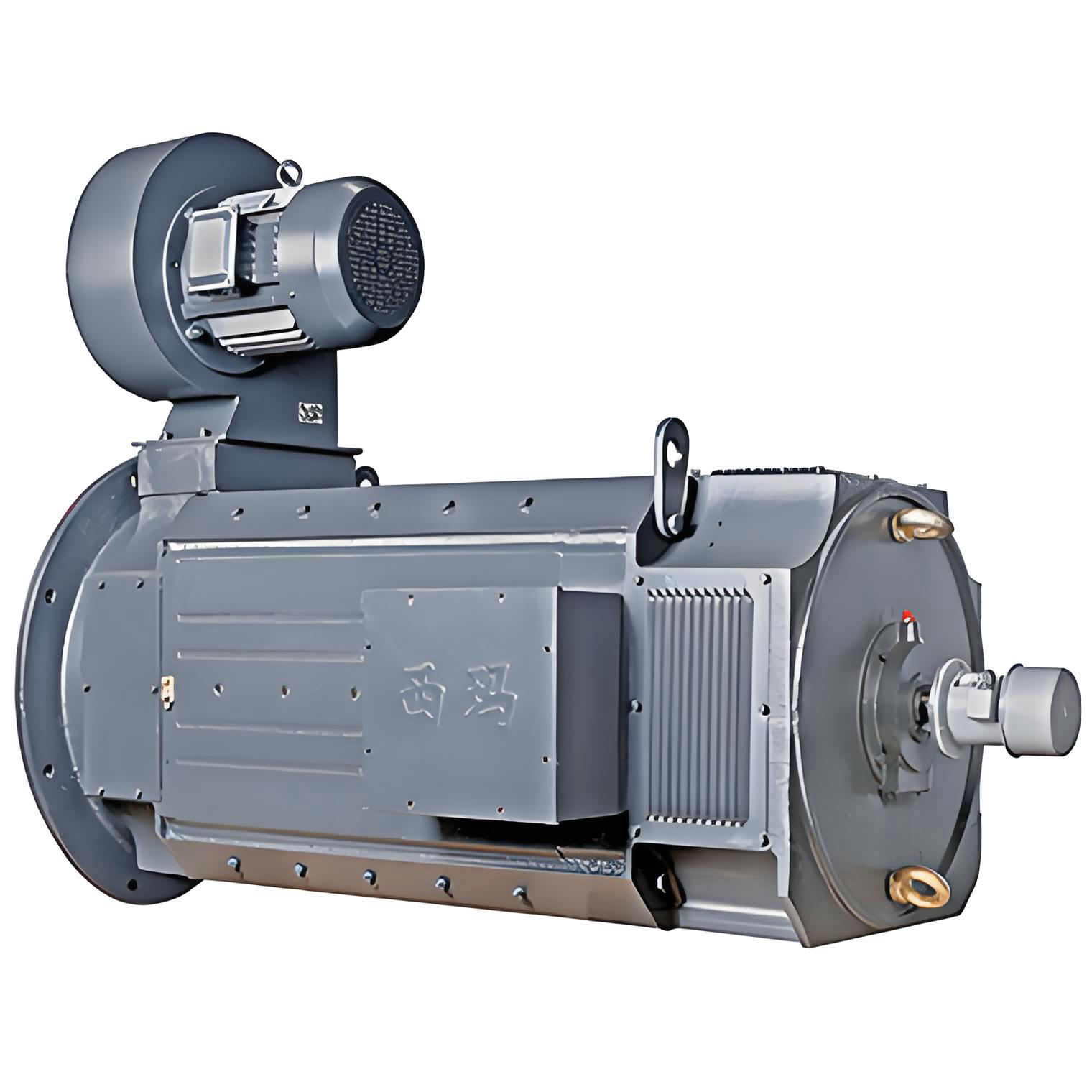

They deliver excellent electrical conductivity, stable commutation, and extended service life, making them ideal for applications in industrial motors, power equipment, and transportation systems.

02 Core Technical Features

1. Premium Material Properties

- Advanced Material Formulation: High-purity graphite combined with copper, silver, and other metal powders for superior conductivity and wear resistance.

- Optimized Structure: Porous design promotes stable oxide film formation, enhancing commutation performance.

- Temperature Resilience: Maintains stable electrical and mechanical properties across -40℃ to +120℃.

2. Outstanding Electrical Performance

- Low Contact Voltage Drop: Minimal contact resistance reduces energy loss.

- Excellent Commutation: Suppresses sparking effectively for smooth operation.

- High Current Capacity: Rated current density up to 12–15 A/cm² with strong overload tolerance.

3. Stable Mechanical Properties

- Uniform Wear: Ensures long lifespan with consistent wear patterns.

- Balanced Hardness: Shore hardness 60–120, preventing excessive wear on commutators.

- Self-Lubrication: Reduces friction and prolongs commutator life.

03 Technical Specifications

| Parameter Category | Technical Specifications |

|---|---|

| Resistivity | 5–50 μΩ·m |

| Rated Current Density | 12–15 A/cm² |

| Max Linear Speed | 70 m/s |

| Shore Hardness | 60–120 |

| Flexural Strength | ≥15 MPa |

| Bulk Density | 1.6–2.2 g/cm³ |

| Operating Temperature | -40℃ to +120℃ |

04 Product Series and Applications

1. Electro-Graphite Brushes

- Features: Moderate hardness, higher resistivity, excellent commutation.

- Applications: DC motors, turbo generators, asynchronous motors.

- Typical Uses: Rolling mill motors, winches, cranes.

2. Metal Graphite Brushes

- Features: High copper content, low resistivity, high current density.

- Applications: Low-voltage DC motors, charging generators.

- Typical Uses: Automotive starter motors, electroplating power supplies.

3. Resin-Bonded Graphite Brushes

- Features: High mechanical strength, impact resistance.

- Applications: High-speed motors, harsh operating conditions.

- Typical Uses: High-speed grinders, centrifuges.

05 Product Advantages

1. Performance Advantages

- Stable Operation: Smooth motor running with minimal vibration.

- Low Sparking: Maintains spark level ≤1¼ under normal conditions.

- Long Lifespan: Up to 30% longer life compared to standard brushes.

2. Quality Advantages

- Strict Quality Control: Monitored from raw material to finished product.

- Precision Tolerances: Ensures proper fit and optimal contact.

- Consistency: Uniform performance across batches for easy group replacement.

3. Service Advantages

- Expert Selection Guidance: Professional support for choosing the right brush.

- After-Sales Guarantee: Comprehensive technical and quality assurance.

- Fast Delivery: Sufficient stock to meet urgent requirements.

06 Selection Guide

Selection Considerations

- Motor Type: AC, DC, or generator specifications.

- Operating Conditions: Load type, duty cycle, and environmental factors.

- Technical Parameters: Voltage, current, and speed requirements.

- Installation Space: Brush dimensions, spring pressure, and mechanical constraints.

Selection Recommendations

- Heavy-Duty Motors: Metal graphite brushes for high current density and conductivity.

- High-Speed Motors: Electro-graphite brushes for mechanical strength and superior commutation.

- Precision Equipment: Resin-bonded graphite brushes for stable operation and low sparking.

07 Installation and Maintenance

Installation Tips

- Surface Bedding: New brushes should be bedded to ensure ≥80% commutator contact.

- Spring Pressure: Adjust to 15–25 kPa for optimal performance.

- Simultaneous Replacement: Replace all brushes in the same motor to maintain balance.

Maintenance Guidelines

- Regular Inspection: Monitor brush wear and replace when necessary.

- Cleanliness: Keep brush holders and brushes free of dust and debris.

- Operational Monitoring: Check spark levels and identify abnormalities promptly.

08 Fault Diagnosis

- Excessive Sparking: Adjust spring pressure or brush position; check commutator condition.

- Rapid Wear: Check current density and environmental dust exposure.

- Poor Contact: Ensure proper bedding and contact area.

09 Service and Support

- Technical Consultation: Expert guidance for brush selection and application.

- Installation Assistance: Detailed manuals and professional support.

- After-Sales Assurance: Comprehensive quality guarantee.

- Technical Support: Troubleshooting for operational issues.

Conclusion

SIMO Motor carbon brushes combine premium materials, advanced manufacturing, and strict quality control to deliver stable performance and long service life. Selecting SIMO carbon brushes ensures reliable motor operation, reduced maintenance costs, and enhanced equipment efficiency.

Choosing SIMO Motor carbon brushes means choosing trustworthy quality and dependable service, helping industrial operations achieve peak performance and longevity.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206