Excerpt:

The high voltage solid-state soft starter cabinet provides smooth and controlled starting for high-voltage motors. It reduces inrush current, prevents mechanical stress, and ensures reliable, energy-efficient motor operation in demanding industrial applications.

High-Voltage Solid-State Soft Starter Cabinet: Intelligent Motor Starting Solution & Core Technology Analysis

01 Product Overview: Advanced High-Voltage Motor Starting Control

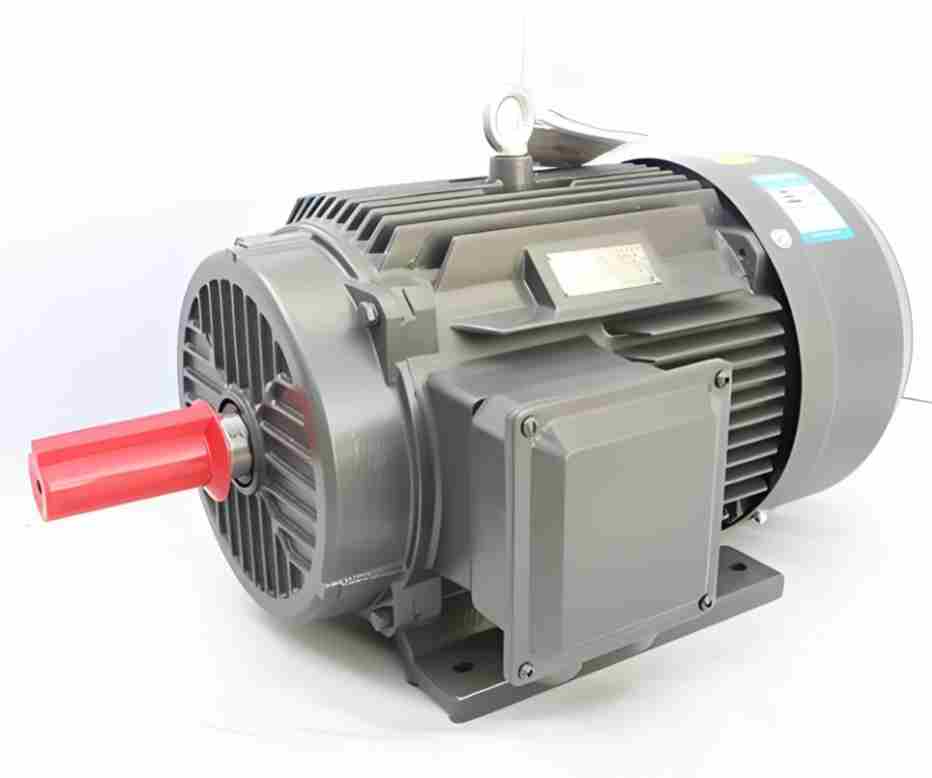

The High-Voltage Solid-State Soft Starter Cabinet is an advanced motor starting device using power electronics and intelligent microprocessor control, designed for 3kV to 15kV AC motors. Utilizing thyristor (SCR) phase control, it enables smooth voltage and current ramp-up, eliminating issues like high inrush currents, mechanical stress, and energy wastage caused by traditional direct-on-line starting.

Widely applied in power systems, metallurgy, mining, chemical, and water treatment industries, this device is a key component for modern industrial automation and high-voltage motor control.

02 Core Technology & Structural Design

1. Intelligent Control Principle

- Microprocessor-Based Control (CPU): Precision SCR firing angle control via fiber-optic isolation.

- Flexible Start Modes: Includes constant-current start, voltage ramp start, and torque control.

- Automatic Bypass: Bypass contactor engages when the motor reaches rated speed, ensuring full-voltage efficient operation.

2. Precision Structure & Safety Features

- Three-Chamber Isolation: Power module, control relay chamber, and main circuit connection chamber independently isolated for high anti-interference capability.

- Multiple Protection Mechanisms: RC snubber units and static/dynamic voltage balancing; overload capacity of 125% continuous and 500% for 60 seconds.

- Modular Components: SCR modules, motor protection modules, communication modules, and control transformers enable fast maintenance and expansion.

03 Core Functions & Advantages

1. Multi-Mode Start & Stop

- Current-Limited Soft Start: Limits inrush current to 100–500% of rated current, avoiding voltage dips.

- Voltage Ramp Control: Adjustable initial torque (10–80% of rated voltage) for smooth acceleration.

- Soft Stop Function: Gradually reduces voltage to eliminate water hammer in pumps, protecting piping systems.

2. Intelligent Diagnostics & Communication

- HMI Interface: LCD display shows three-phase current, fault logs, and runtime; supports multilingual interface.

- Remote Monitoring: RS-485 interface supports Modbus/Profibus-DP; integrates with DCS/PLC for centralized control.

- Fault Traceability: Stores last three faults with data for fast diagnostics.

3. Energy Efficiency & Cost Savings

- Reduces transformer capacity by over 40% compared to direct-on-line start.

- Example: 800kW pump application reduces transformer from 4500kVA to 2500kVA, saving over $60,000 in initial investment and lowering annual electricity consumption by 23,000 kWh.

04 Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 3kV, 3.3kV, 6kV, 6.6kV, 10kV (AC -15%~+10%) |

| Insulation Level | 42kV/1min, max 42kV |

| Power Range | 250kW–25,000kW |

| Overload Capacity | 125% continuous, 500% for 60s |

| Operating Temperature | -20℃~50℃ |

| Altitude | ≤2000m |

| Humidity | ≤90% |

| Protection Level | IP42/IP54 optional |

| Control Power | AC 220V/50Hz, 600VA |

05 Application Scenarios & Industry Solutions

1. Typical Load Applications

- Pumps: High-lift, circulation, and supply pumps; eliminates water hammer.

- Fans & Compressors: Soft start protects high-inertia loads with extended acceleration time.

- Heavy Machinery: Ball mills, crushers, conveyors, mixers; reduces mechanical stress.

2. Industry Cases

- Gansu Jingdian Phase II Pump Station: RNMV series successfully started 32 high-voltage pumps with smooth operation and energy savings.

- Steel & Cement: Applications in Hebei Baoxing Steel and Shanxi Tongli Cement; extends equipment life under frequent stop-start conditions.

- Overseas Project: 50,000-ton Malaysian paper plant uses high-voltage soft starter meeting international standards.

06 Selection & Installation Guide

1. Key Selection Factors

- Motor parameters: voltage, power, starting torque, load type.

- Environment: altitude, temperature, protection level (IP42/IP54), explosion-proof requirements.

- Function: communication protocols (Modbus/Profibus), soft stop, remote control.

2. Installation & Maintenance

- Incoming Cabinet: Must be paired with vacuum circuit breakers for short-circuit capacity compatibility.

- Cooling: Natural cooling; ensure adequate ventilation in high-temperature environments.

- Maintenance: Periodically inspect RC snubbers, SCR modules, and fiber-optic trigger circuits.

07 Core Advantages of Simo High-Voltage Solid-State Soft Starter

- Certified Technology: GB/IEC compliance; proprietary core software.

- Reliability: Imported power devices, strict parameter matching, designed for >100,000 hours service life.

- Full Lifecycle Support: One-stop service from design, commissioning, to training; lifetime upgrades available.

Simo High-Voltage Solid-State Soft Starter Cabinet offers advanced control, intelligent protection, energy efficiency, and operational reliability, making it an ideal solution for modern industrial high-voltage motor applications, ensuring safe, cost-effective, and long-lasting motor operation.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206