Excerpt:

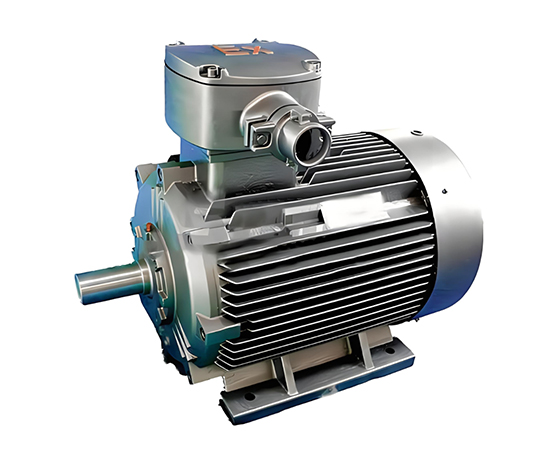

The fully enclosed liquid resistance starter cabinet provides smooth and controlled motor starting while protecting internal components from dust, moisture, and external interference. It reduces inrush current, prevents mechanical stress, and ensures safe and reliable motor operation in industrial environments.

Fully Enclosed Liquid Resistance Starter Cabinet: High-Performance Motor Starting Solution

01 Product Overview

The Fully Enclosed Liquid Resistance Starter Cabinet is an advanced starting solution for medium and large wound-rotor asynchronous motors, offering smooth, low-impact starts and exceptional adaptability in harsh industrial environments.

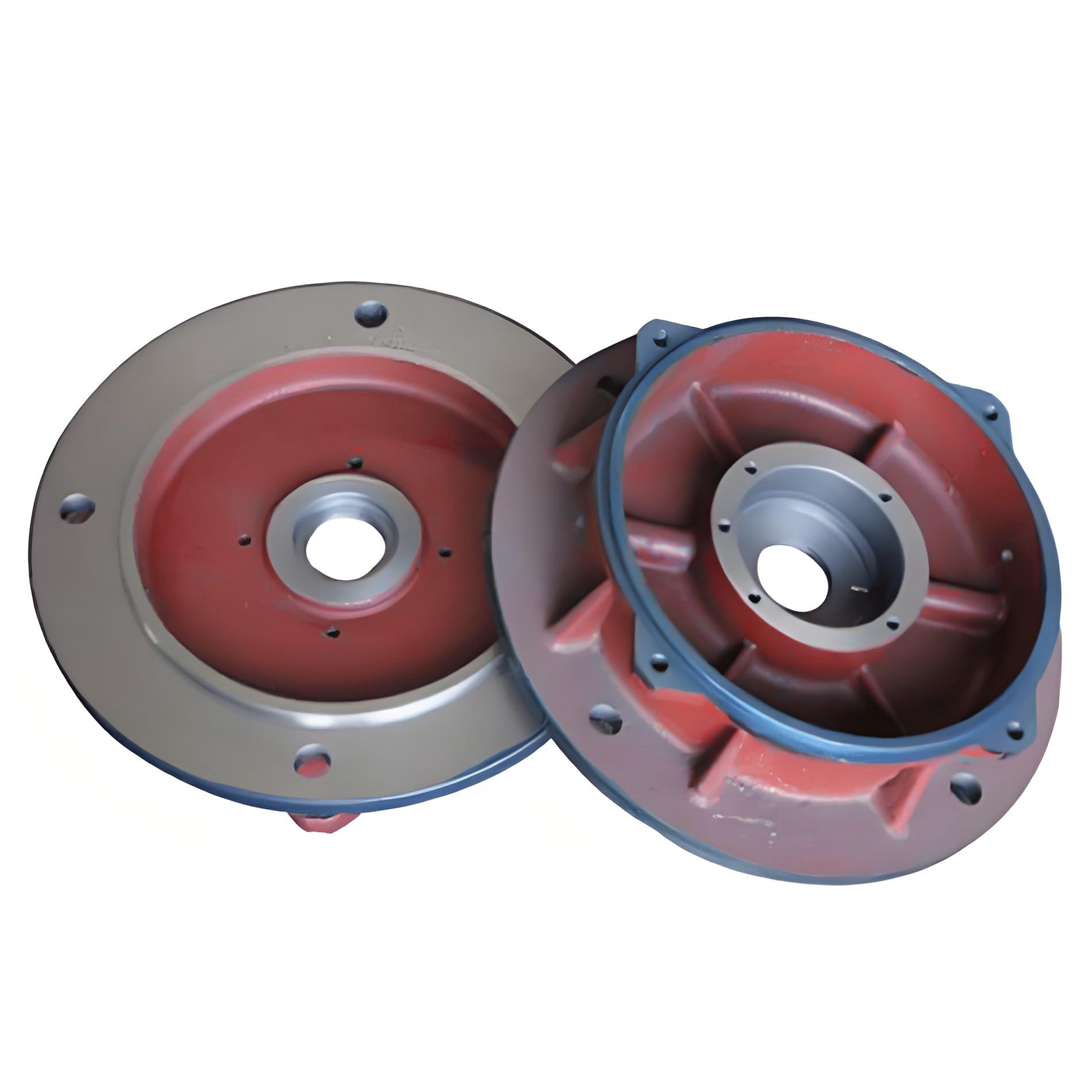

This system inserts specially formulated liquid resistors into the motor rotor circuit and adjusts electrode positions to vary resistance, achieving soft, shock-free motor starting. Its fully enclosed design with self-circulating cooling and precision sealing eliminates issues like rapid electrolyte evaporation and ensures continuous starting capability.

02 Working Principle & Technical Features

1. Intelligent Start Principle

The starter operates by varying the liquid resistance in the rotor circuit. Upon receiving a start command, a small servo motor moves the electrodes, gradually reducing resistance.

When the resistance reaches its minimum, a shorting contactor closes, connecting the motor rotor star point directly. This enables low-current, high-torque smooth starts, minimizing mechanical stress and reducing grid impact.

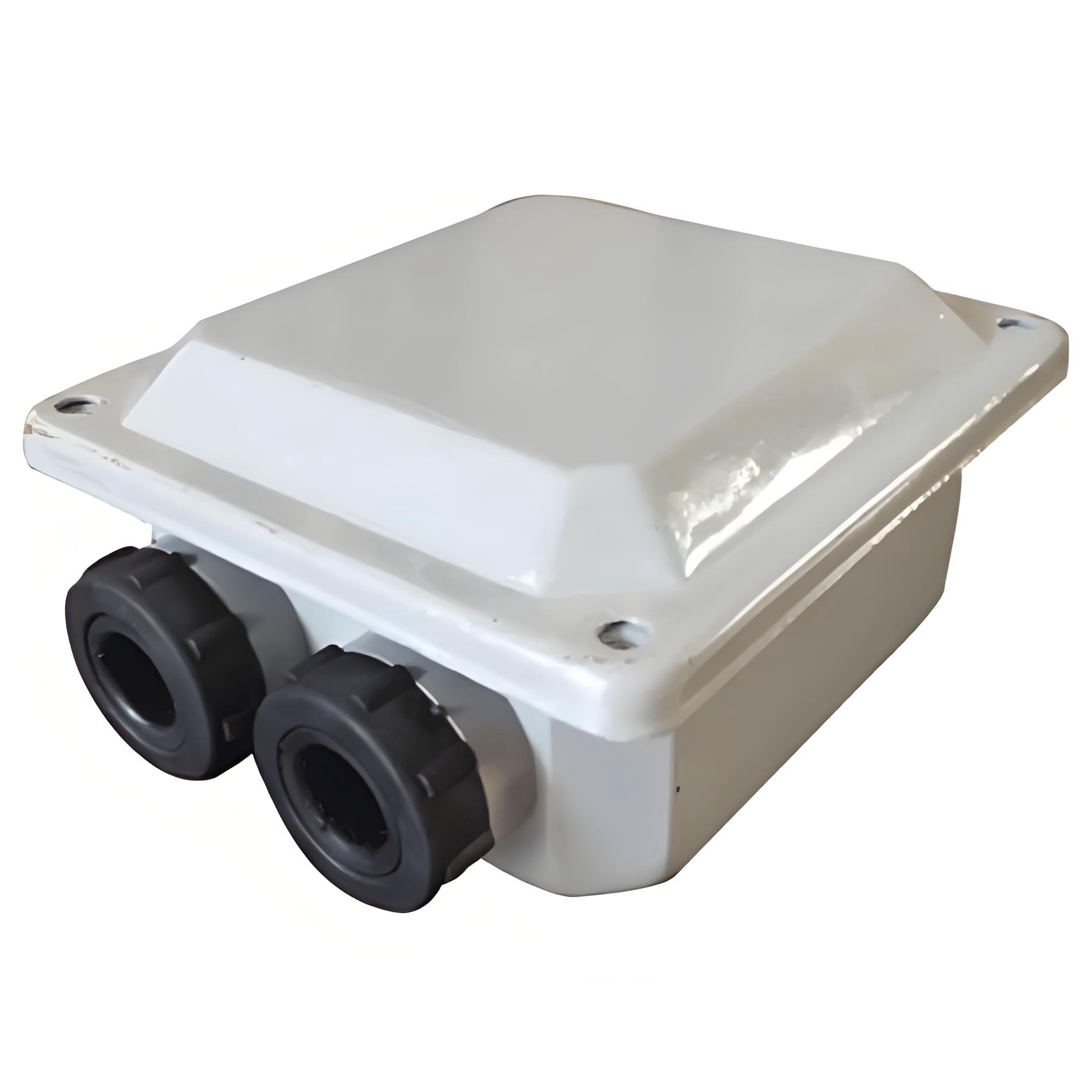

2. Fully Enclosed Advantages

- Sealed System: All cabinet and tank surfaces are fully enclosed, with precision seals on electrode lifting rods, fixed plate connections, and tank lids.

- Self-Circulating Cooling: Integrated pumps and internal piping rapidly dissipate heat from the electrolyte tank.

- Environmental Adaptability: Suitable for dry climates with annual precipitation below 200mm, ensuring reliable operation in harsh conditions.

03 Core Structure & Innovative Design

1. Modular Design

The cabinet consists of fully enclosed casing, contactor compartment, control box, and circulation system, enhancing reliability and facilitating safe maintenance.

- Fully Enclosed Cabinet: Only the front panel is movable; all other surfaces are sealed, achieving IP54+ protection.

- Dedicated Electrolyte Tank: Equipped with insulating lifting frames, moving and fixed electrodes, ensuring balanced three-phase resistance.

- Electrode Drive Mechanism: Uses a worm gear lift system connected to the lifting frame via insulated rods for smooth, quiet operation.

2. Advanced Sealing Technology

- Lifting Rod Seal: Prevents vapor escape during movement.

- Fixed Electrode Outlet Seal: Multi-layer sealing prevents leakage.

- Pressure Relief Valve: Maintains normal sealing and releases excess pressure automatically.

04 Performance Features & Advantages

- Low Starting Current: ≤1.3× rated current, minimizing grid impact.

- Continuous Start Capability: Can perform 5–10 consecutive starts.

- Low Voltage Adaptability: Starts reliably even under voltage drops (e.g., 6 kV motor starts at 5.5 kV).

- Smooth, Shock-Free Operation: Extends motor and mechanical equipment life.

- Easy Maintenance: Automated operation, convenient installation and upkeep, reducing service frequency.

05 Application Fields

- Heavy Industry: Cement, chemical, steel, metallurgy, mining industries (75–10,000 kW wound-rotor motors).

- Harsh Environments: Long-term operation in dry climates with low precipitation.

- Special Conditions: Multiple consecutive starts, unstable or low-voltage grids.

Common applications include ball mills, rolling mills, crushers, fans, and other heavy-load motor drives, making it a superior alternative to traditional variable-resistor starters.

06 Technical Specifications

| Parameter | Specification |

|---|---|

| Applicable Motor | Wound-rotor asynchronous motor |

| Rated Voltage | 380V–10kV |

| Power Range | 75–10,000 kW |

| Ambient Temperature | -25℃–+50℃ |

| Altitude | ≤2000 m |

| Protection Level | IP54+ |

| Continuous Starts | 5–10 cycles |

| Relative Humidity | ≤90% |

07 Selection & Installation Guidelines

Selection Considerations

- Motor model, rated power, rotor voltage/current, and speed.

- Load characteristics and operating conditions.

- Installation environment requirements.

- Cabinet appearance and color preferences.

Installation Requirements

- Stable, vibration-free location.

- No corrosive gases.

- Tilt ≤5°.

- No fire or explosion hazards.

- Power supply: three-phase AC 380V ±10%.

- Special design needed for temperatures < -5℃ or altitudes >2000m.

08 Maintenance & Troubleshooting

- Routine Checks: Maintain electrolyte level; refill distilled water if below line.

- Seal Inspection: Ensure all sealing components are intact and leak-free.

- Circulation System Check: Verify pumps and piping function properly for effective cooling.

- Protection Verification: Regularly test over-temperature, low liquid level, and over-time protections.

The Fully Enclosed Liquid Resistance Starter Cabinet ensures stable, efficient, and safe motor starting even in extreme industrial environments. Its advanced design, automated operation, and robust protection make it an ideal solution for medium and large motor applications in cement, metallurgy, mining, chemical, and heavy industry sectors.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206