Excerpt:

The liquid resistance speed control cabinet is designed to regulate motor speed using liquid resistance technology. It provides smooth acceleration, precise speed adjustment, and reliable performance for industrial motors in heavy-duty applications.

Liquid Rheostat Speed Control Cabinet: Efficient and Smooth Motor Speed Solution

01 Product Overview

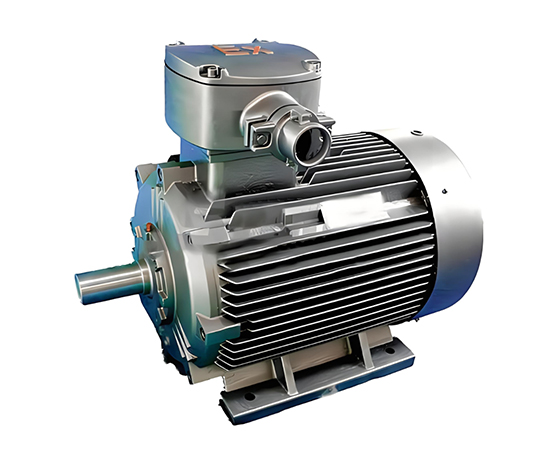

The Liquid Rheostat Speed Control Cabinet (also called liquid resistor starter or water resistor cabinet) is designed for medium and large wound-rotor asynchronous motors, providing soft start and smooth speed control. It uses an electrolyte solution as the conductive medium, adjusting the rotor circuit resistance to control motor speed and startup current.

Widely applied in building materials, metallurgy, mining, petroleum, and chemical industries, this cabinet ensures stable motor operation, energy savings, and extended equipment life.

02 Working Principle & Technical Features

1. Intelligent Working Principle

- Operates on the conductivity of electrolyte solution.

- Adjusts resistance by changing electrode distance or electrolyte concentration in the solution.

- For fans and pumps, the system adjusts resistance according to P ∝ n³ (P = shaft power, n = speed), enabling smooth speed control and energy savings.

- For metallurgy rolling mills, it reduces inrush currents at startup, protecting the motor.

2. Key Technical Features

- Smooth stepless speed control: Adjust resistance continuously for smooth startup.

- High thermal capacity: Supports 5–10 consecutive starts without overheating.

- Low starting current: ≤1.3× rated current (Iq ≤ 1.3 Ie).

- Low voltage starting: Can start successfully when supply voltage drops 10% below rated voltage.

- Durable structure: Resistant to 160℃, service life up to 20+ years.

03 Core Structure & Components

- Cabinet Body

- Welded frame with powder-coated surfaces.

- High moisture, heat, and corrosion resistance, IP20/IP30 protection.

- Sealed design prevents dust ingress.

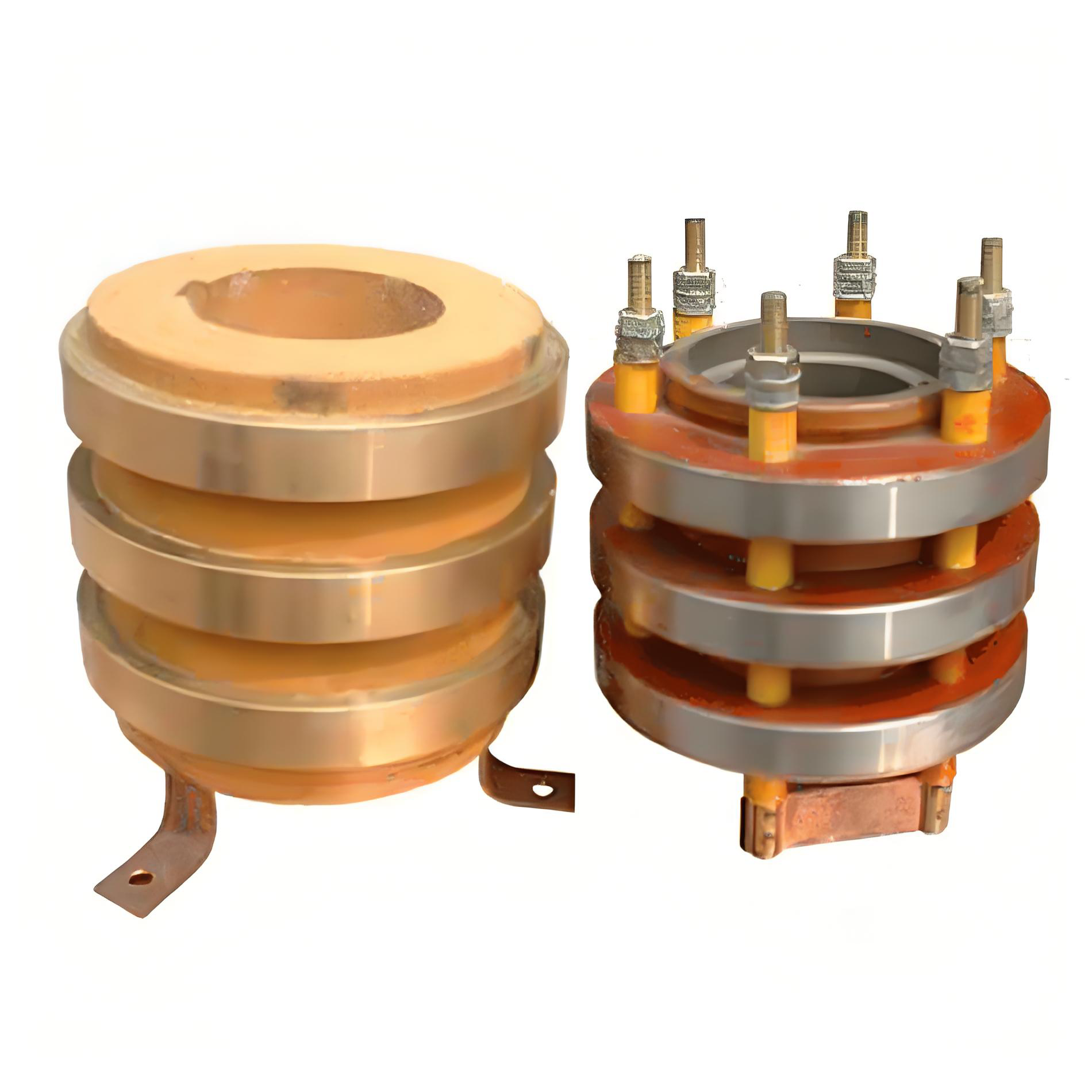

- Conductive Electrode Plates

- Made of copper with rare metal plating, corrosion-resistant and maintenance-free.

- Proper insulation ensures safety and reliability.

- Liquid Rheostat System

- Constructed from high-temperature resistant PTFE plastics.

- Electrolyte: sodium carbonate solution, high conductivity and thermal capacity.

- Each cell equipped with static electrodes, insulated with high-voltage heat-shrink sleeves.

- Electrical Control System

- Centralized control unit for operation, protection, display, and execution.

- Optional HMI interface for remote monitoring and control.

04 Performance Features & Advantages

- Energy Efficiency

- Reduces energy consumption in fan and pump applications by 10–30%.

- Superior Starting Performance

- Smooth startup, minimal mechanical stress, extending motor and equipment life.

- Starting current ≤ 1.3× rated current.

- High success rate, unaffected by voltage fluctuations or load variations.

- Reliable Protection

- Multiple protections: startup timeout, overvoltage, over-travel, overtemperature.

- No harmonic pollution; improves power factor (COS φ increase 0.18–0.22) compared with series reactors.

05 Application Areas

Heavy Industry

- Building Materials: Cement mills, crushers, fans.

- Metallurgy: Rolling mills, compressors, fans.

- Mining: Hoists, crushers, conveyors.

Energy & Infrastructure

- Petrochemical: Pumps, compressors.

- Power Industry: Boiler feedwater pumps, fans, induced draft fans.

Applicable Motors

- Voltage: 380V–10kV

- Power: 75–10,000 kW

- Suitable for high-inertia loads and heavy-duty startup scenarios.

06 Technical Specifications

| Parameter | Specification |

|---|---|

| Voltage Range | 380V–10kV |

| Power Range | 75–10,000 kW |

| Starting Current | ≤1.3× rated current |

| Speed Control Ratio | Fan/pump loads approx. 2:1 |

| Energy Saving Rate | Fan/pump loads approx. 10–30% |

| Electrolyte Working Temp | 5–60℃ |

| Protection Level | IP20, IP30 |

| Ambient Temperature | -40℃ to +50℃ |

07 Selection & Installation Guidelines

Selection Considerations

- Motor parameters: Rated power, stator/rotor voltage and current.

- Load characteristics: Type (fan, pump, mill), inertia.

- Environment: Temperature, humidity, altitude.

- Optional features: Remote monitoring, automation.

Installation Requirements

- Temperature: -40℃ to +50℃

- Relative humidity ≤90%

- Altitude ≤2000m (custom design for higher)

- Floor inclination ≤5°

- No fire, explosion, corrosive substances, or vibration hazards

08 Maintenance & Troubleshooting

Regular Checks

- Electrolyte level and concentration

- Electrode condition: Clean if corroded or fouled

- Insulation resistance: Ensure safe operation

Common Issues

- Abnormal resistance: Check electrolyte or electrode position

- Overheating: Verify cooling system and ambient conditions

- Reduced startup performance: Replace or adjust electrolyte

The Liquid Rheostat Speed Control Cabinet provides smooth startup, reliable performance, and energy savings, making it the ideal solution for medium and large wound-rotor motors. Its simple structure, easy maintenance, and broad industrial application make it widely used in building materials, metallurgy, mining, petroleum, and chemical sectors.

It continues to play a key role in industrial energy saving and automated motor control, delivering economic benefits and operational efficiency.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206