Excerpt:

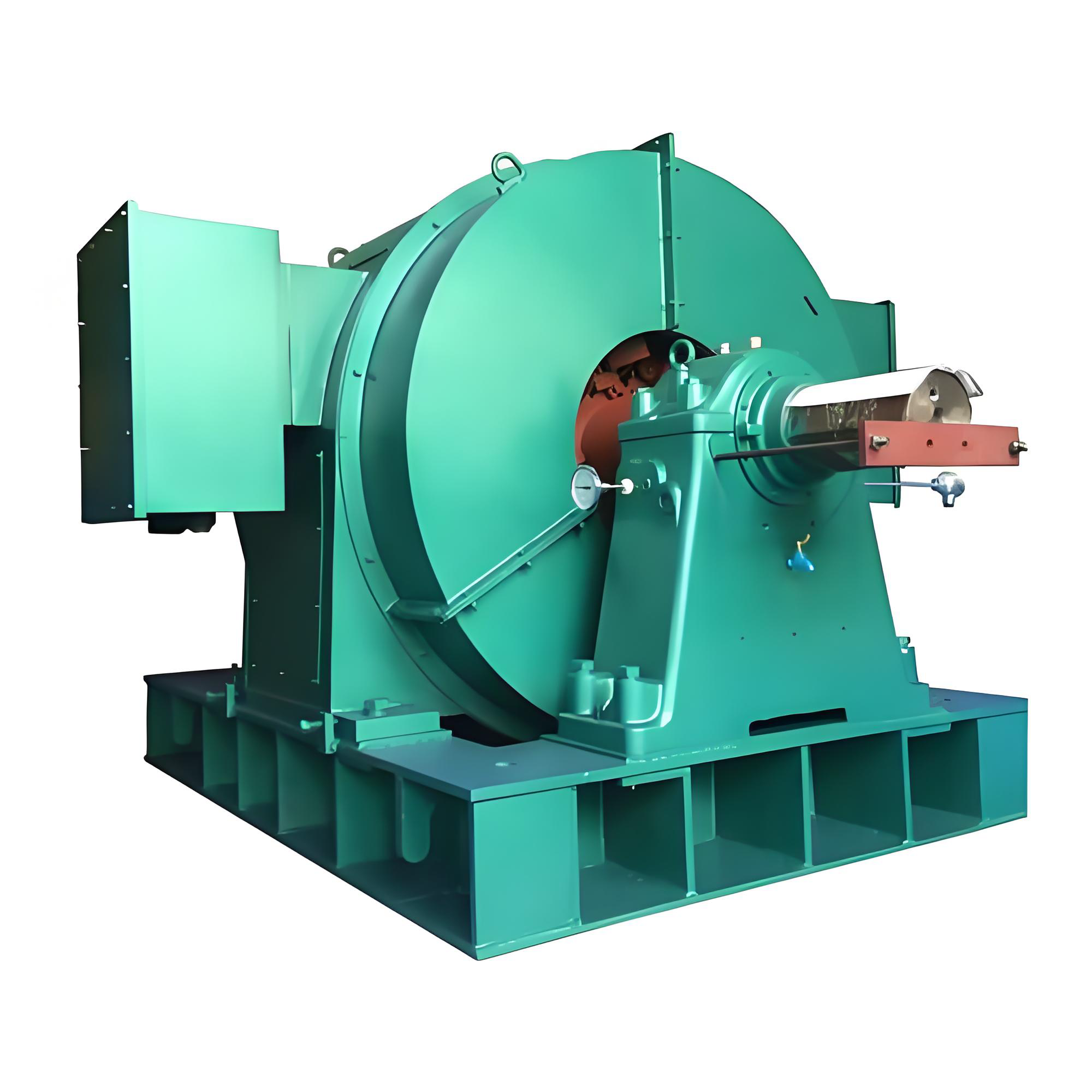

The DC speed control cabinet is designed to regulate the speed of DC motors efficiently and reliably. It provides smooth acceleration, precise speed adjustment, and stable operation for industrial applications such as manufacturing, processing, and automation systems.

DC Speed Control Cabinet: Precision Control and High-Efficiency Industrial Drive Solution

01 Product Overview

The DC Speed Control Cabinet from Simo Motor is a high-precision control system designed for industrial DC motors. Utilizing advanced power electronics and intelligent control algorithms, it delivers accurate speed and torque regulation while ensuring stable operation.

This cabinet integrates thyristor rectification technology, PID closed-loop control, and multiple protection functions, making it ideal for industries such as metallurgy, mining, hoisting, textile, and printing, where precise speed control is essential.

Modular design and intelligent control provide a reliable, energy-efficient DC motor control solution, adaptable to various industrial operating conditions.

02 Core Technical Features

1. Precision Speed Control

- Wide Range Adjustment: Speed ratio up to 1:20 (standard) or 1:100 (extended) to meet diverse process requirements.

- High Accuracy: Static accuracy ≤1%, dynamic accuracy ≤3%.

- Multiple Operation Modes: Supports constant torque and constant power modes.

- Smooth Speed Regulation: Stepless adjustment minimizes mechanical shocks.

2. Intelligent Control System

- PID Closed-Loop Control: Adaptive PID algorithms automatically optimize control parameters.

- Digital Triggering Technology: Ensures symmetrical and stable pulse output.

- Multiple Signal Interfaces: 4-20mA, 0-10V standard inputs for easy integration.

- Communication Support: RS485, Profibus protocols for system connectivity and remote monitoring.

3. Multi-Layer Protection

- Overcurrent Protection: Rapid detection and power cut-off.

- Overvoltage/Undervoltage Protection: Monitors supply voltage fluctuations.

- Overspeed Protection: Monitors motor speed in real-time to prevent overspeed.

- Temperature Protection: Protects critical components from overheating.

- Phase Loss Protection: Detects power phase loss to safeguard the rectifier system.

03 Technical Specifications

| Parameter | Specification |

|---|---|

| Input Power | 3-phase AC 380V±10%, 50/60Hz |

| Speed Range | 1:20 (standard), 1:100 (wide range) |

| Control Accuracy | Static ≤1%, Dynamic ≤3% |

| Load Type | Constant torque / Constant power selectable |

| Ambient Temperature | -10℃~+40℃ |

| Protection Level | IP20, IP42 optional |

| Control Mode | Local / Remote Control |

04 Application Fields

Heavy Industry

- Metallurgy: Rolling mills, coilers, straighteners.

- Mining: Hoists, crushers, conveyors.

- Hoisting Equipment: Bridge and gantry cranes.

Manufacturing

- Textile Machinery: Spinning and weaving speed coordination.

- Printing Equipment: Precise speed control for printing and laminating machines.

- Plastic Machinery: Extruders, injection molding machines.

Special Industrial Applications

- High Inertia Loads: Fans, pumps with smooth start-up.

- Precision Control Processes: Production requiring stable speed control.

- Harsh Environments: High temperature, high humidity conditions.

05 Product Advantages

Performance Advantages

- Fast Response: Advanced algorithms with response time <100ms.

- Stable Operation: Comprehensive protections ensure reliable long-term operation.

- Energy Efficient: Power factor >0.9, efficiency >95%.

- Easy Maintenance: Modular design with advanced diagnostic functions.

Technical Advantages

- Intelligent Optimization: Automatically identifies load characteristics and optimizes control.

- High Compatibility: Supports various DC motor specifications.

- Flexible Expansion: Interfaces reserved for future upgrades.

- User-Friendly Operation: Intuitive interface for simple parameter configuration.

06 Selection Guidelines

Key Selection Factors

- Motor Specifications: Voltage, current, power, rated speed.

- Load Characteristics: Load type, inertia, torque requirements.

- Speed Requirements: Range, control accuracy, dynamic response.

- Environmental Conditions: Temperature, humidity, protection level.

Configuration Recommendations

- Standard Configuration: For general industrial applications.

- Enhanced Configuration: For high-precision dynamic control.

- Special Configuration: For harsh industrial environments, enhanced protection.

07 Installation & Maintenance

Installation Requirements

- Environment: Well-ventilated, no corrosive gases or conductive dust.

- Electrical Conditions: Stable supply voltage, reliable grounding.

- Space: Adequate ventilation and maintenance access.

Maintenance

- Daily Checks: Monitor operation, temperature, and noise.

- Regular Maintenance: Clean filters, tighten connections, inspect components.

- Professional Servicing: Recommend semi-annual professional inspection and maintenance.

08 Service & Support

Simo Motor provides comprehensive technical support:

- Technical Consultation: Expert advice and tailored solutions.

- Installation Guidance: On-site professional assistance.

- Operator Training: Specialized training for personnel.

- After-Sales Warranty: 24-month warranty with lifetime technical support.

Conclusion

The Simo Motor DC Speed Control Cabinet offers advanced technology, reliable performance, and full-service support, making it an ideal choice for industrial DC drive applications. It enhances equipment efficiency, reduces energy consumption, and improves production stability.

For detailed specifications or customized solutions, contact the Simo Motor technical team for expert guidance and professional consultation.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206