High Voltage Motor with Forced Ventilation

Date: 2026-01-25Views: 3889

Excerpt:

High Voltage Motor with Forced Ventilation: An OverviewHigh voltage motors are essential components in various industrial applicati

High Voltage Motor with Forced Ventilation: An Overview

High voltage motors are essential components in various industrial applications, providing reliable and efficient operation in demanding environments. One of the key features that enhance their performance and longevity is forced ventilation. Here, we provide a comprehensive overview of high voltage motors with forced ventilation, discussing their design, applications, benefits, and maintenance considerations.

What is Forced Ventilation?

Forced ventilation refers to the method of enhancing airflow around a motor to regulate its temperature. Unlike passive ventilation (which relies on natural airflow), forced ventilation employs fans or blowers to circulate air. This process cools the motor more effectively, particularly under heavy load conditions.

Design Features

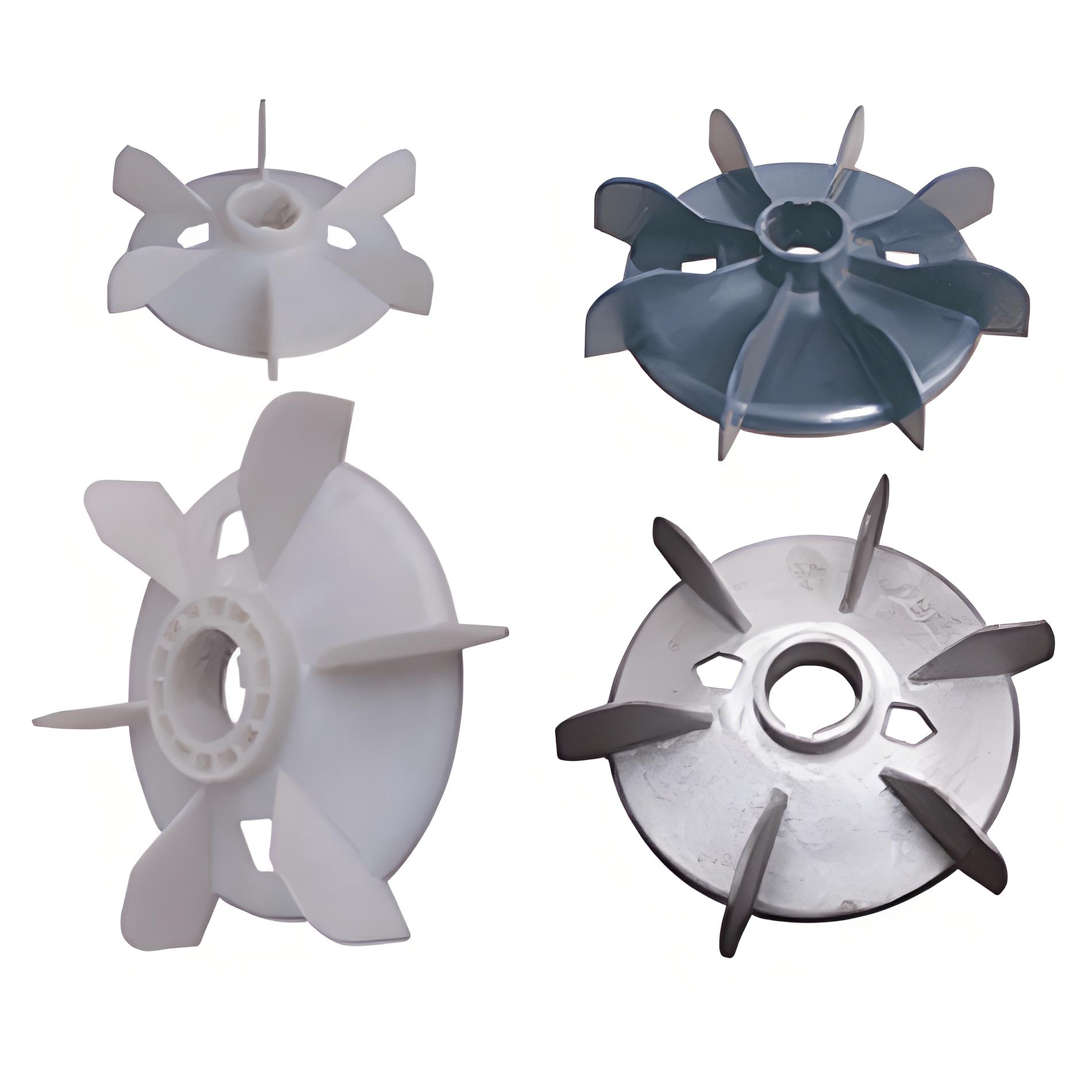

- Cooling System: High voltage motors with forced ventilation often include a dedicated fan and duct system that directs air across the motor windings.

- Enclosure: These motors typically feature an IP (Ingress Protection) rating to prevent dust and moisture ingress, ensuring that the internal components are safeguarded from environmental factors.

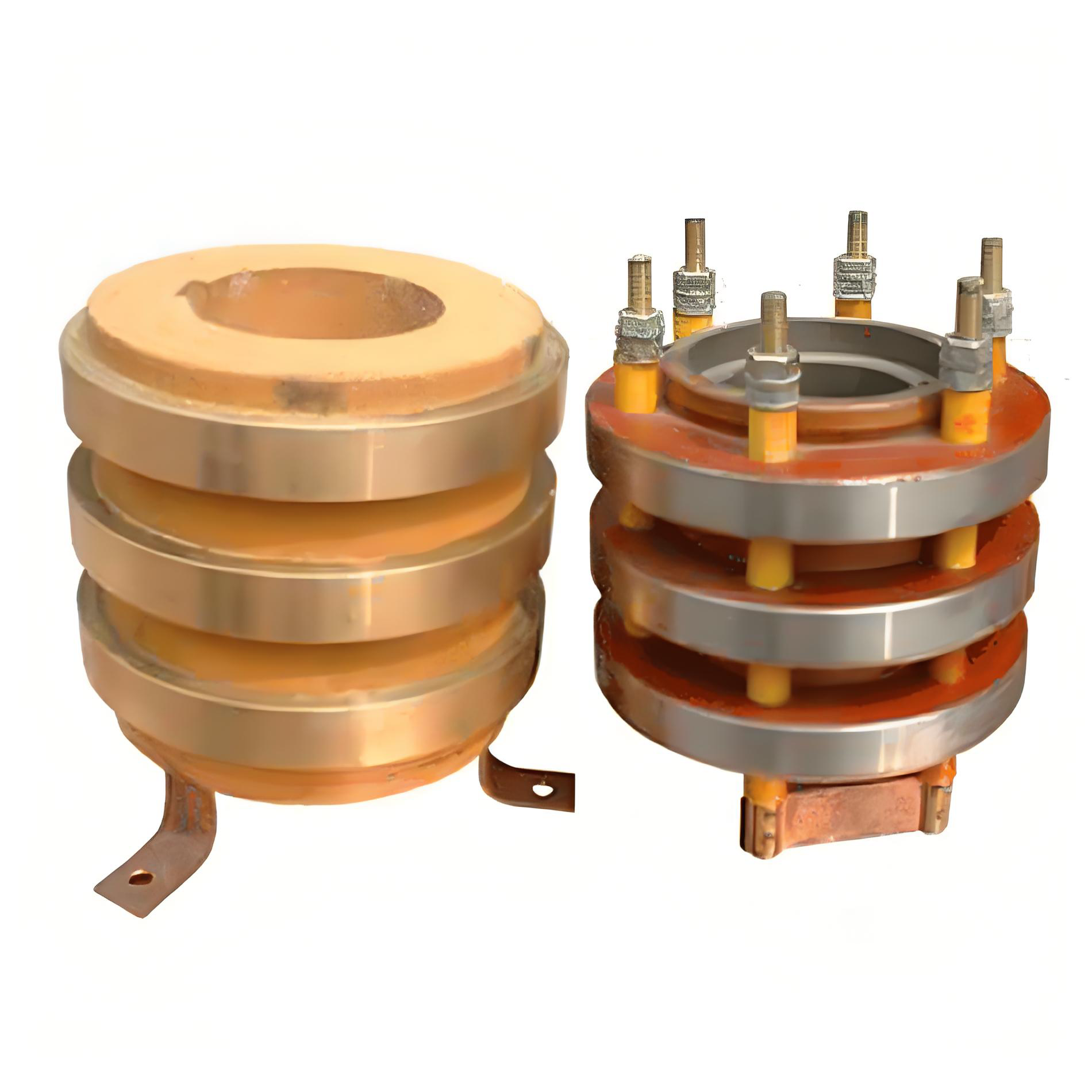

- Bearings: High-quality bearings are critical to support the rotor under forced ventilation conditions, minimizing friction and heat generation.

- Thermal Sensors: Many motors are equipped with thermal sensors that monitor temperature, allowing for real-time adjustments and protection against overheating.

Applications

High voltage motors with forced ventilation are utilized across various sectors, including:

- Manufacturing: Driving machinery such as conveyors, pumps, and compressors.

- Mining: Operated in harsh conditions, requiring robust cooling solutions.

- HVAC: Supporting large-scale heating, ventilation, and air conditioning systems.

- Marine: Used in ship propulsion and other onboard systems where high reliability is essential.

Benefits

- Improved Efficiency: Enhanced cooling allows for higher efficiency during operation, reducing energy consumption and operating costs.

- Extended Lifespan: Effective temperature management diminishes wear on electrical components, leading to longer service intervals.

- Increased Load Capacity: High voltage motors can handle larger loads and more strenuous conditions, making them suitable for a broader range of applications.

- Safety Enhancements: By employing forced ventilation, the risk of overheating and subsequent failures is significantly reduced, promoting safer operations.

Maintenance Considerations

- Regular Inspection: Routine checks of the cooling system, fan operation, and air filters are crucial to maintain optimal performance.

- Cleaning: Dust and debris can hinder airflow; thus, regular cleaning of the ventilation pathways is necessary.

- Thermal Management: Monitoring temperature readings can preemptively identify potential issues, allowing for timely interventions.

- Lubrication: Ensuring that bearings and moving parts are adequately lubricated can prevent overheating and mechanical failure.

![[关键词] [关键词]](https://www.simomotores.com/wp-content/uploads/2025/11/1764032285-993331.jpg)

Conclusion

High voltage motors with forced ventilation are vital for reliable and efficient operation in various demanding applications. Their robust design and cooling capabilities enhance performance and lifespan, making them an excellent choice for industries that require high reliability under heavy loads. Implementing regular maintenance and monitoring practices is essential to maximize uptime and ensure the longevity of these powerful machines.

By understanding the intricacies of high voltage motors with forced ventilation, businesses can make informed decisions that align with their operational needs and goals.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206