Excerpt:

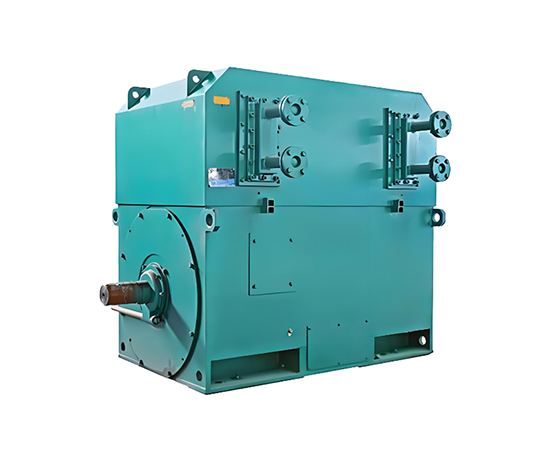

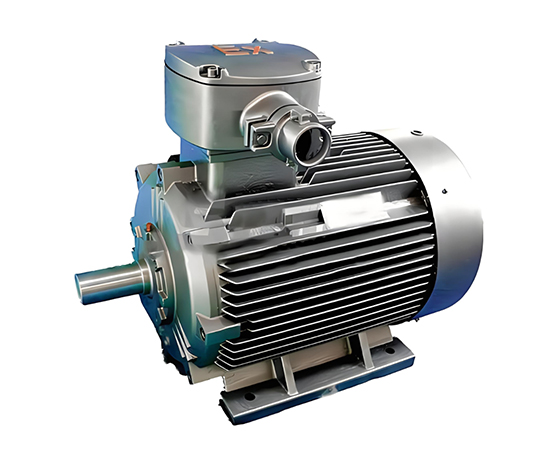

The YBE2 series explosion-proof high-efficiency three-phase asynchronous motor is designed for industrial applications in hazardous environments. Featuring a flameproof structure and high energy efficiency, it ensures reliable and safe operation in industries such as petrochemical, chemical processing, and mining.

YBE2 Series Explosion-Proof High-Efficiency Three-Phase Asynchronous Motor: A Safe and Reliable Industrial Power Solution

In industries such as petroleum, chemical processing, and coal mining, the YBE2 Series Explosion-Proof High-Efficiency Three-Phase Asynchronous Motor stands out for its excellent explosion-proof safety and superior energy efficiency, making it an ideal power solution for hazardous and potentially explosive environments.

The YBE2 series explosion-proof high-efficiency three-phase induction motor is a totally enclosed, self-fan-cooled, squirrel-cage, flameproof motor independently developed by Xi’an Xima Motor Co., Ltd., combining advanced international technology with decades of manufacturing experience. This motor series features outstanding explosion-proof safety, high efficiency, reliable operation, and long service life, and is specifically designed for hazardous locations where explosive gas mixtures may be present.

1. Product Overview and Technical Features

1.1 Product Introduction

The YBE2 series explosion-proof high-efficiency three-phase asynchronous motor is one of Xima Motor’s key products in the explosion-proof motor field. With frame sizes ranging from H132 to H355, it meets a wide range of power ratings and installation requirements.

This series is designed and manufactured in strict accordance with GB 18613-2012 (Energy Efficiency Limits and Grades for Small and Medium Three-Phase Asynchronous Motors), meeting Grade 3 energy efficiency, which is equivalent to IE2 efficiency level under IEC 60034-30. It provides users with a cost-effective, energy-saving, and environmentally friendly industrial drive solution.

1.2 Core Technical Advantages

- Advanced explosion-proof design: Fully compliant with GB 3836.1 and GB 3836.2 standards. The flameproof enclosure effectively prevents internal explosions from spreading to the external environment, ensuring maximum operational safety in hazardous areas.

- High efficiency and energy savings: Optimized electromagnetic design and low-loss materials significantly improve efficiency, reducing energy consumption and operating costs compared with conventional explosion-proof motors.

- Robust mechanical structure: Totally enclosed construction with IP55 protection class, effectively preventing dust, moisture, and contaminants from entering the motor, ensuring reliable operation in harsh industrial environments.

2. Technical Parameters and Performance

Main Technical Specifications

- Frame size range: H132–H355

- Rated voltage: 380V, 660V, 380V/660V (other voltages available on request)

- Rated frequency: 50Hz

- Protection class: IP55

- Insulation class: F

- Cooling method: IC411 (self-fan-cooled, TEFC)

- Duty type: S1 (continuous duty)

- Explosion-proof marking: Exd I, Exd II AT4, Exd II BT4 (depending on application)

- Mounting types: IMB3, IMB5, IMB35, etc.

Performance Highlights

- High efficiency and energy saving, meeting GB18613-2012 Grade 3 and IE2 standards

- Low noise and low vibration, ensuring smooth and stable operation

- Wide voltage adaptability, maintaining stable performance under power supply fluctuations

3. Structural Design and Configuration

3.1 Main Motor Structure

- Flameproof enclosure: Manufactured from high-strength materials with sufficient mechanical strength to withstand internal explosion pressure without deformation or damage, preventing flame propagation.

- Optimized cooling system: Totally enclosed self-fan-cooled structure with parallel and vertical cooling fins, ensuring excellent heat dissipation and continuous stable operation under rated load.

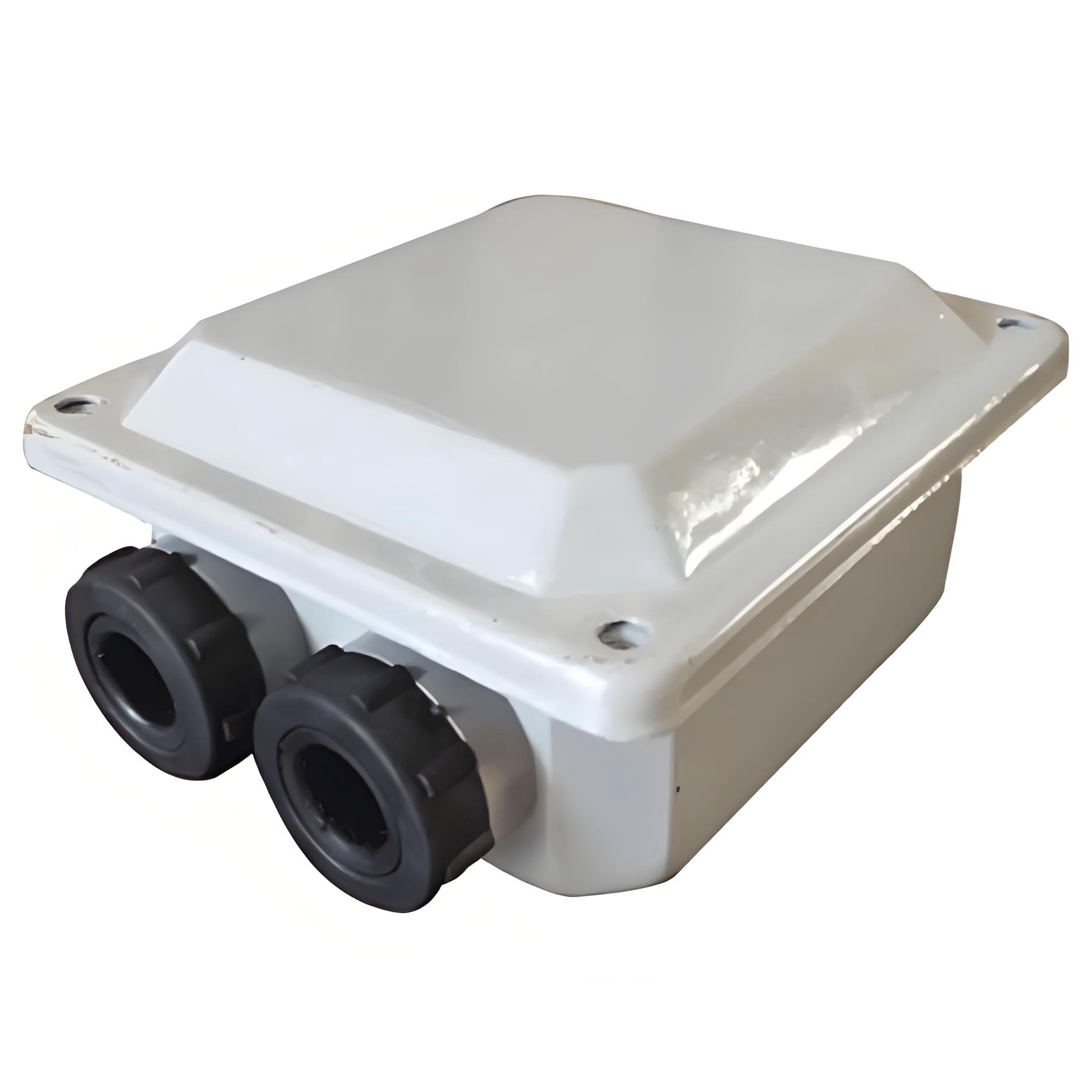

- Explosion-proof terminal box: Special flameproof design with cylindrical spigot flameproof joints and “O”-ring sealing, providing enhanced explosion-proof safety and reliable cable connection.

3.2 Internal Core Components

- Stator: F-class insulation system with reliable insulation performance and long service life; optimized design for efficient energy conversion.

- Rotor: Manufactured with high-quality materials and precision processes, featuring excellent dynamic balance for smooth and reliable operation.

- Bearing system: Proper bearing configuration according to frame size; larger frame motors are equipped with online grease injection devices for easy maintenance and extended service life.

4. Applications and Industries

The YBE2 series explosion-proof high-efficiency three-phase asynchronous motor is widely used in various hazardous industrial environments:

4.1 Petrochemical Industry

- Oil and gas drilling and extraction equipment

- Pumps, compressors, and process equipment in chemical plants

- Fans and pumps in refineries operating in explosive atmospheres

4.2 Coal Industry

- Fixed underground coal mine equipment (non-mining faces), such as pumps and ventilation systems

- Coal preparation plants and coal processing machinery operating in dusty environments

4.3 Other Hazardous Locations

- Industrial sites with explosive gas mixtures

- Customized versions available for outdoor use (W), humid and tropical environments (TH), and dry hot climates (TA)

5. Product Advantages and Value

5.1 Safety and Reliability

- Strict compliance with national explosion-proof standards

- Advanced flameproof structure ensuring safe operation in explosive environments

- Optional protection devices such as bearing temperature monitoring and winding overheat protection

5.2 High Energy Efficiency

- Reduced operating costs through high-efficiency design

- Improved power factor and reduced reactive power losses

- Lower total lifecycle cost due to energy savings and reduced maintenance requirements

5.3 Easy Maintenance

- User-friendly structural design for inspection and servicing

- Modular components reduce maintenance complexity and spare parts inventory

- Long service life with F-class insulation and large thermal margin

6. Installation and Operation Guidelines

- Suitable for environments with ambient temperatures up to 35°C (underground mines) or 40°C (industrial plants), minimum -15°C

- Installation altitude ≤1000 m

- Relative humidity up to 95% at 25°C (underground) or monthly average 90% (industrial)

- Requires a solid, level foundation and precise alignment when coupled to driven equipment

- Electrical connections must strictly follow nameplate data and explosion-proof installation standards

7. Service and Technical Support

Xi’an Xima Motor Co., Ltd. has established a comprehensive quality assurance system to guarantee the superior quality of the YBE2 series motors:

- Full compliance with GB 755-2008, GB 3836 series, and related international standards

- Strict inspection and testing throughout manufacturing

- Every motor undergoes no-load, load, and dielectric strength testing before delivery

After-Sales Service

- Professional technical support for selection, installation, and commissioning

- Fast response to quality feedback and on-site service when required

- Long-term technical support and service commitment

With its excellent explosion-proof performance, high efficiency, and reliable operation, the YBE2 Series Explosion-Proof High-Efficiency Three-Phase Asynchronous Motor is a trusted industrial power solution for hazardous environments. Backed by continuous technological innovation and strict quality control, Xima Motor ensures stable, safe, and efficient power for demanding industrial applications.

Choosing the Xima YBE2 series means choosing safety, efficiency, and professional service for your industrial operations.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206