Excerpt:

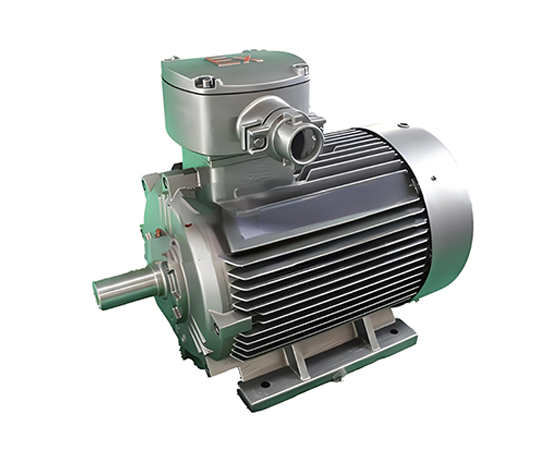

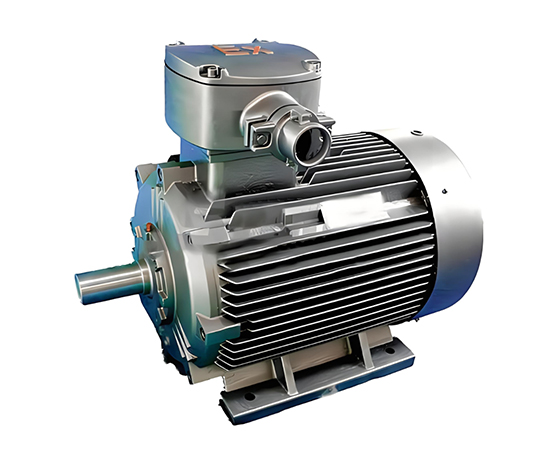

The YBK3 series explosion-proof three-phase asynchronous motor is specifically designed for underground coal mine applications. Featuring a flameproof structure, robust insulation, and reliable performance, it ensures safe and efficient operation in harsh and hazardous mining environments.

YBK3 Series Explosion-Proof Three-Phase Asynchronous Motor for Underground Coal Mines: A Safe, High-Efficiency Power Solution

In the coal mining industry, the YBK3 series explosion-proof three-phase asynchronous motor has become an indispensable power solution for underground operations, thanks to its outstanding explosion-proof safety and high energy efficiency. It is specifically engineered to ensure reliable, stable, and efficient performance in harsh and hazardous mining environments.

The YBK3 series underground coal mine explosion-proof motor is a high-efficiency, energy-saving power unit designed exclusively for underground coal mine conditions. Utilizing advanced flameproof (Ex d) technology and optimized electromagnetic design, this series delivers excellent explosion-proof safety, high efficiency, reliable operation, and long service life. The motors strictly comply with GB 3836.1-2010 and GB 3836.2-2010 national standards, making them an ideal driving solution for coal mine working faces and fixed underground equipment.

1. Product Overview and Key Features

1.1 Product Positioning and Application Scope

The YBK3 series explosion-proof motor is purpose-built for harsh underground coal mine environments. With an explosion protection marking of Exd I Mb, it is suitable for mining areas containing methane gas or coal dust, as well as other hazardous locations with explosive gas mixtures.

Developed on the basis of the YBK2 series and integrated with advanced domestic electromagnetic technology, the YBK3 series offers high efficiency, energy savings, long service life, low noise, and an advanced explosion-proof structure. The welded steel frame, reinforced fan cover, terminal box, and insulation system enable the motor to operate reliably under severe underground conditions.

1.2 Core Technical Advantages

- Advanced explosion-proof design: The flameproof enclosure remains intact during internal explosions, preventing flame transmission through flameproof joints and eliminating the risk of external ignition.

- High energy efficiency: Motor efficiency meets GB 18613-2012 Grade 2 energy efficiency requirements, equivalent to IEC 60034-30 IE3 efficiency level, delivering significant energy savings.

- Robust mechanical structure: Protection class IP55, insulation class F, large thermal margin, and extended service life ensure stable long-term operation.

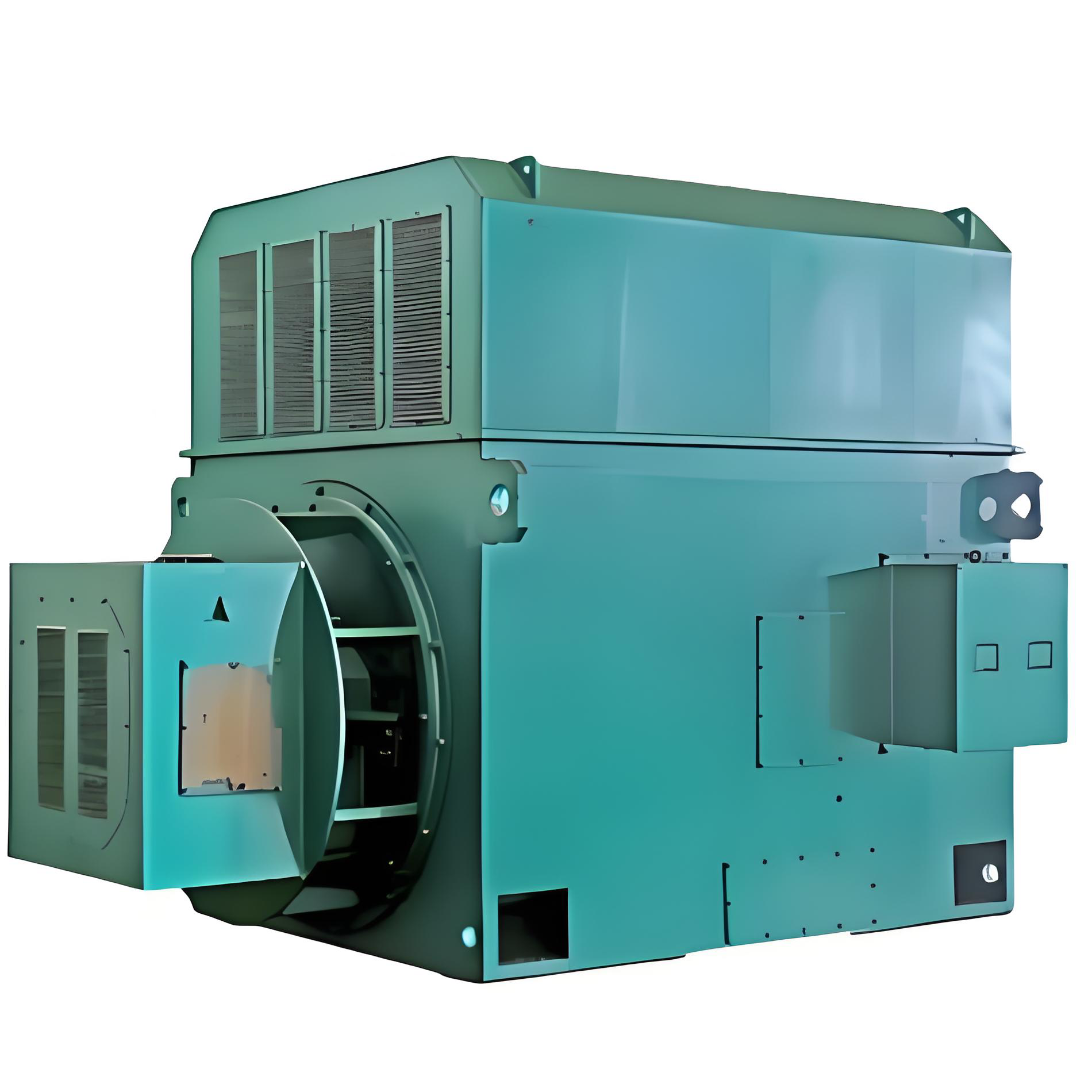

2. Technical Parameters and Performance

Main Technical Specifications

- Frame size: H80–H355

- Rated voltage: 380V, 660V, 1140V, 380/660V, 660/1140V

- Rated frequency: 50Hz

- Protection class: IP55

- Insulation class: F

- Cooling method: IC411 (Totally Enclosed Fan Cooled)

- Duty type: S1 (Continuous duty)

- Explosion-proof marking: Exd I Mb

- Mounting types: IMB3, IMB5, IMB35

Performance Characteristics

- High efficiency and energy saving, reducing operating costs

- Low noise and low vibration, achieved through optimized rotor and bearing systems

- Wide voltage adaptability, ensuring stable operation under varying underground power conditions

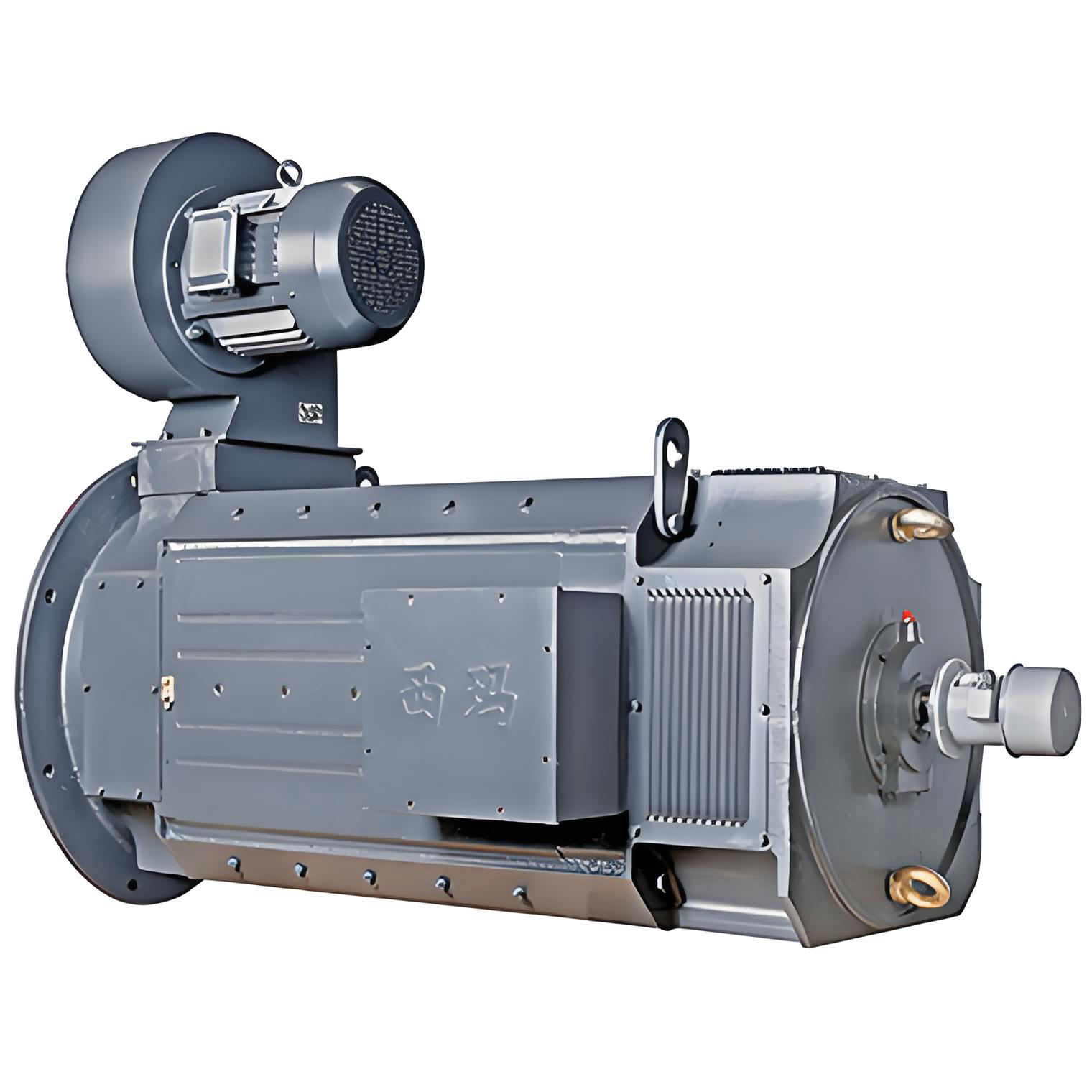

3. Structural Design and Configuration

3.1 Main Motor Structure

- Flameproof enclosure: Key components such as frame, end shields, bearing covers, and terminal box undergo a 1.5 MPa static pressure test for at least 10 seconds, ensuring no deformation or leakage that could compromise explosion protection.

- Optimized cooling system: Fully enclosed fan-cooled structure with parallel and vertical cooling fins; anti-static plastic fan with low inertia and low loss; steel fan cover providing maximum airflow and excellent heat dissipation.

- Explosion-proof terminal box: Top-mounted terminal box with spacious wiring cavity, supporting rubber-sheathed cables, armored cables, steel conduits, or flexible conduits; equipped with six terminals for easy connection.

3.2 Internal Core Components

- Stator: High-strength polyester enameled copper wire with VPI vacuum pressure impregnation, offering excellent electrical, mechanical, moisture-resistant, and thermal stability.

- Rotor: Cast aluminum rotor, dynamically balanced for smooth operation, low vibration, and high efficiency; high-quality silicon steel laminations reduce losses.

- Bearing system: Special low-noise, low-vibration bearings; sealed bearings for smaller frames and oil injection/drain devices for larger frames, allowing lubrication without shutdown.

4. Application Areas

The YBK3 series explosion-proof high-efficiency motor is widely used in coal mining operations, including:

- Mining and cutting equipment at underground working faces

- Fixed underground equipment, such as pumps and ventilation systems

- Conveying and hoisting machinery, including conveyors and elevators

Applicable Environmental Conditions

- Ambient temperature: -15°C to +35°C (underground coal mines)

- Altitude: ≤1000 m

- Relative humidity: ≤95% at 25°C

- Power supply fluctuation: Voltage ±5% (short-term ±10%), frequency ±2% (short-term ±5%)

5. Product Value and Advantages

5.1 Safety and Reliability

- Fully compliant with national explosion-proof standards

- High-strength fasteners with spring washers prevent loosening

- Optional protection devices: stator temperature monitoring, bearing temperature monitoring, anti-condensation heaters

5.2 Energy Efficiency and Economic Benefits

- Power range from 0.75 kW to 315 kW, suitable for various applications

- High efficiency and power factor reduce energy consumption and operating costs

- Low total lifecycle cost due to reduced maintenance and energy savings

5.3 Easy Maintenance

- User-friendly structure for inspection and servicing

- Modular design simplifies maintenance and spare parts management

- Long service life with F-class insulation and generous thermal margin

6. Installation and Operation Guidelines

- Suitable for underground coal mine environments with gas or coal dust

- Solid and level foundation required

- Supports flexible couplings, gear drives, and belt drives

- Multiple starting methods available: DOL, Y/Δ, reduced voltage, VFD

7. Service and Technical Support

- Manufactured in strict compliance with GB 755-2008, GB 3836 series, and relevant IEC standards

- Comprehensive quality inspection and testing during production

- Professional support for selection, installation, commissioning, and after-sales service

The YBK3 series explosion-proof three-phase asynchronous motor for underground coal mines stands out for its superior safety, high efficiency, and reliable performance. It is an ideal power solution for hazardous mining environments, helping enterprises improve safety, reduce energy consumption, and enhance productivity.

Choosing the YBK3 series means choosing reliable explosion-proof safety, energy efficiency, and professional technical support for modern coal mining operations.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206