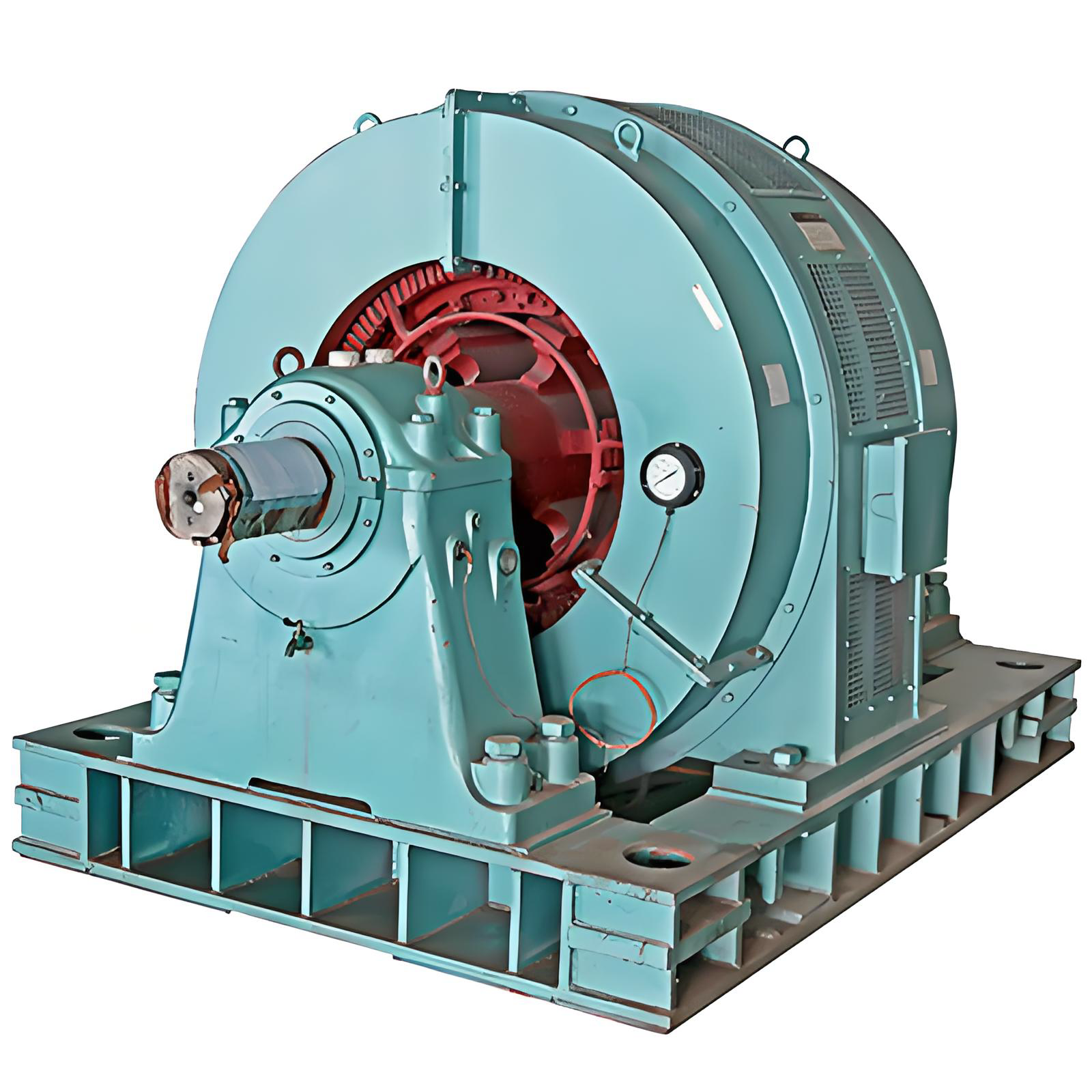

High Voltage Motor for Compressor Application

发布时间:2026-01-23浏览量:2225

摘要:

High Voltage Motors for Compressor ApplicationsOverviewHigh voltage motors are critical components in vario

高压电机s for Compressor Applications

Overview

High voltage motors are critical components in various industrial applications, including compressor systems used in refrigeration, air conditioning, and gas compression processes. These 电机s are designed to operate efficiently at voltages typically above 1,000 volts, and their robust design makes them suitable for demanding industrial environments.

Key Benefits of High Voltage Motors

-

Efficiency: High voltage motors tend to have lower current draw compared to their low voltage counterparts. This results in reduced energy losses, which enhances overall system efficiency.

-

Reduced Conductor Size: Due to the lower current requirements, high voltage motors allow for the use of smaller, lighter gauge wires. This leads to cost savings on materials and installation.

-

Longer Distance Operation: High voltage motors can effectively transmit power over longer distances with minimal voltage drop, making them ideal for large industrial plants.

-

High Power Output: These motors are capable of providing significant power ratings, making them suitable for heavy-duty compressor applications where high torque and consistent operation are crucial.

-

Durability: Designed for harsh industrial environments, high voltage motors often feature robust construction and can withstand high levels of vibration, dust, and moisture.

Applications in Compressors

-

Refrigeration Compressors: High voltage motors are widely used in industrial refrigeration systems to drive cooling compressors, ensuring efficient temperature control in food processing and storage facilities.

-

Gas Compressors: In petroleum and gas industries, high voltage motors are used in natural gas compression units to facilitate the transportation and processing of gas.

-

Air Compression: In manufacturing settings, high voltage motors power air compression systems essential for pneumatic tools and processes.

Types of High Voltage Motors

-

Squirrel Cage Induction Motors: Most commonly used due to their simplicity, reliability, and cost-effectiveness.

-

同步电机s: Suitable for applications requiring precise speed control and high efficiency.

-

Variable Frequency Drive (VFD) Compatible Motors: These motors can adjust their speed according to load requirements, leading to improved energy savings.

Selection Considerations

When selecting a high voltage motor for compressor applications, consider the following factors:

-

Power Rating: Ensure the motor meets the power requirements of your compressor system.

![[关键词] [关键词]](https://www.simomotores.com/wp-content/uploads/2023/08/1764157304-26173732.jpg)

-

Efficiency Rating: Look for high-efficiency models, preferably with IE3 or IE4 ratings, to optimize energy use.

-

Torque Characteristics: Evaluate whether the motor can provide the necessary starting and running torque for your compressor.

-

Environmental Conditions: Take into account the operating environment, including temperature extremes, humidity, and exposure to chemicals.

-

Installation Space: Ensure the physical dimensions of the motor fit within the designated installation space, considering any additional space required for maintenance.

-

Control System Compatibility: Ensure the motor can integrate seamlessly with existing control systems, especially if using VFDs.

Maintenance Tips

-

Regular Inspections: Regularly check for signs of wear and tear, including unusual vibrations and sounds.

-

Lubrication: Maintain proper lubrication of bearings to prevent overheating and wear.

-

Cleaning: Keep the motor and surrounding areas free from dust and debris to prevent overheating.

-

Electrical Checks: Monitor electrical connections and insulation integrity to avoid safety hazards and inefficient operation.

结论

High voltage motors are essential for enhancing the efficiency, reliability, and durability of compressor applications across various industries. By carefully selecting the right motor and implementing effective maintenance strategies, businesses can ensure optimal performance and longevity of their compressor systems.

陕西省公共网络安全号码:41032502000206

陕西省公共网络安全号码:41032502000206