摘要:

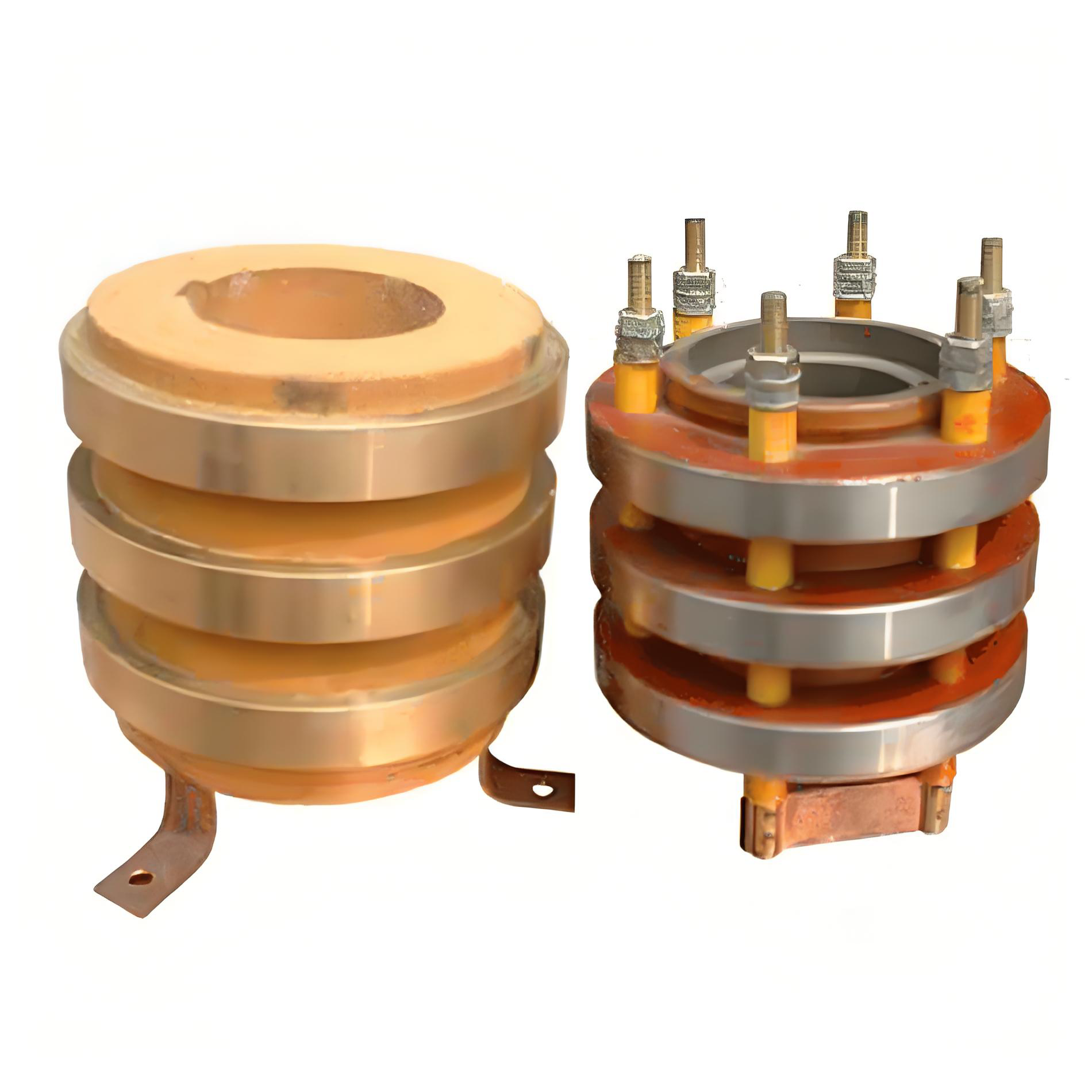

The motor slip ring is an essential component that allows the transmission of electrical signals and power to a rotating part of the motor. It ensures continuous operation, stable current flow, and reliable performance in industrial motors.

SIMO Motor Slip Rings: Precision Rotating Electrical Interface for Efficient Power and Signal Transmission

01 Product Overview: Core Component of Rotating Electrical Systems

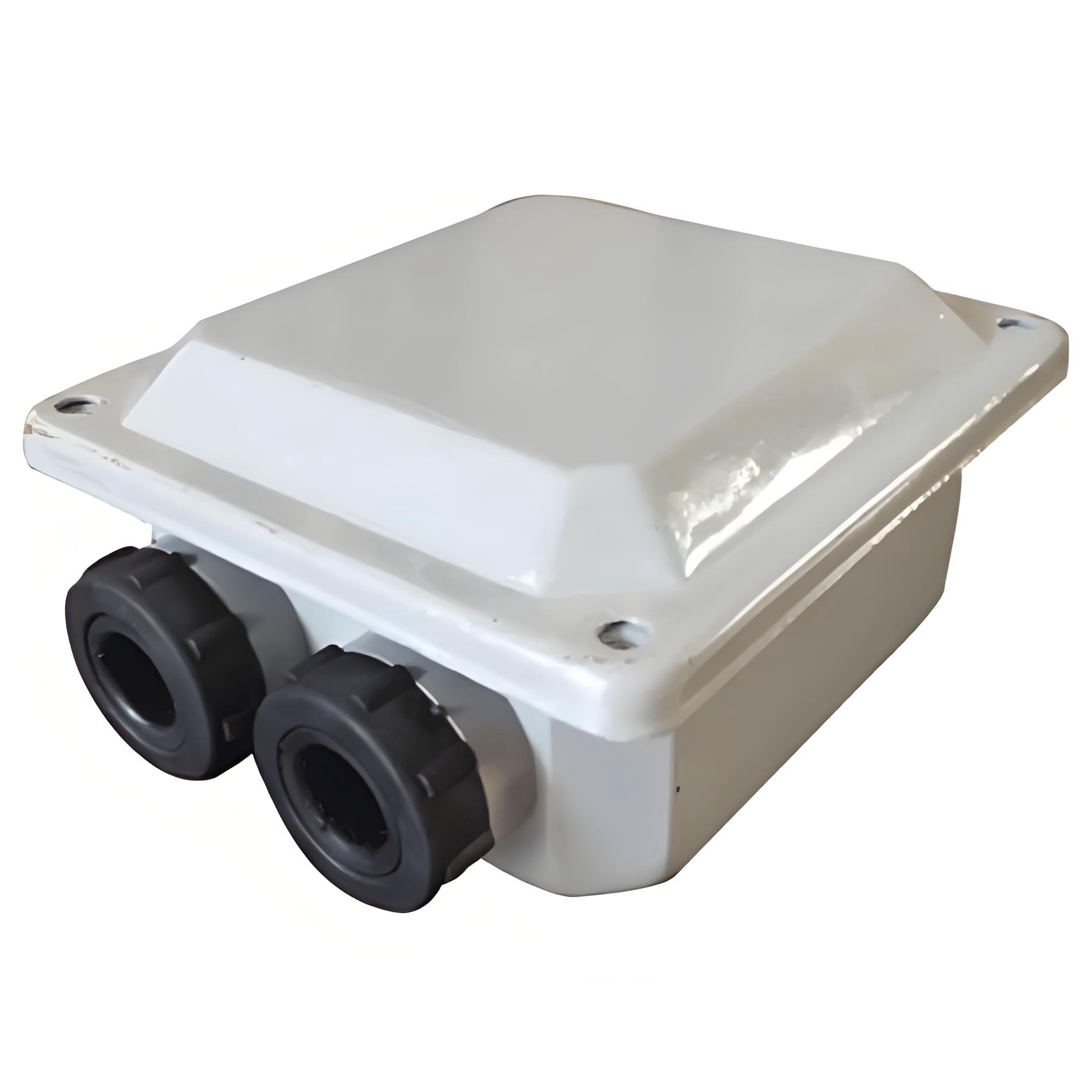

SIMO Motor slip rings (also known as rotary electrical interfaces or collectors) are precision electrical transmission components designed for various rotating electromechanical equipment. Acting as a bridge for power and signal transfer between rotating and stationary structures, SIMO slip rings utilize advanced electrical contact technology and high-качество materials to ensure stable transmission of power, data, and control signals during continuous rotation.

Widely applied in heavy industrial machinery, precision instruments, and advanced electromechanical systems, SIMO slip rings provide excellent conductivity, stable rotational contact, and long service life, making them essential components in motor systems. All products are manufactured under the ISO9001 quality management system, meeting stringent industrial standards.

02 Key Technical Features & Advantages

1. Precision Structure and Material Selection

- High-Quality Materials: Available in steel, copper, or special alloy slip rings. Steel offers superior wear resistance and mechanical strength for high-speed synchronous motors. Copper slip rings deliver exceptional conductivity and low contact resistance.

- Compact Modular Design: Space-saving, flexible installation, and IP65 protection for dust- and moisture-heavy industrial environments.

- Precision Contact System: Ensures stable electrical connection during high-speed rotation. Optional gold-gold contacts achieve extremely low contact resistance and long service life.

2. Superior Electrical and Mechanical Performance

- Efficient Power Transmission: Supports high current up to 600A for large industrial equipment. Rated voltages cover standard industrial levels up to 240VAC or higher.

- Multi-Signal Capability: Simultaneously transmits power, control signals, and data bus protocols (RS485, CANbus, Profibus, Ethernet) for intelligent control.

- Wide Temperature Range: Operates from -30℃ to +80℃, extendable to -40℃ for extreme conditions.

- High-Speed Rotation: Standard models up to 300 RPM, special designs up to 500 RPM for high-speed applications.

3. Long Service Life and Low Maintenance

- Extended Design Life: Optimized contacts and premium materials ensure over 30 million revolutions, with some products offering 2-year maintenance-free guarantees.

- Low Maintenance: Brushless designs reduce maintenance frequency and complexity, lowering total cost of ownership.

- Self-Diagnostic Capability: High-end models include monitoring interfaces to detect potential issues in real-time.

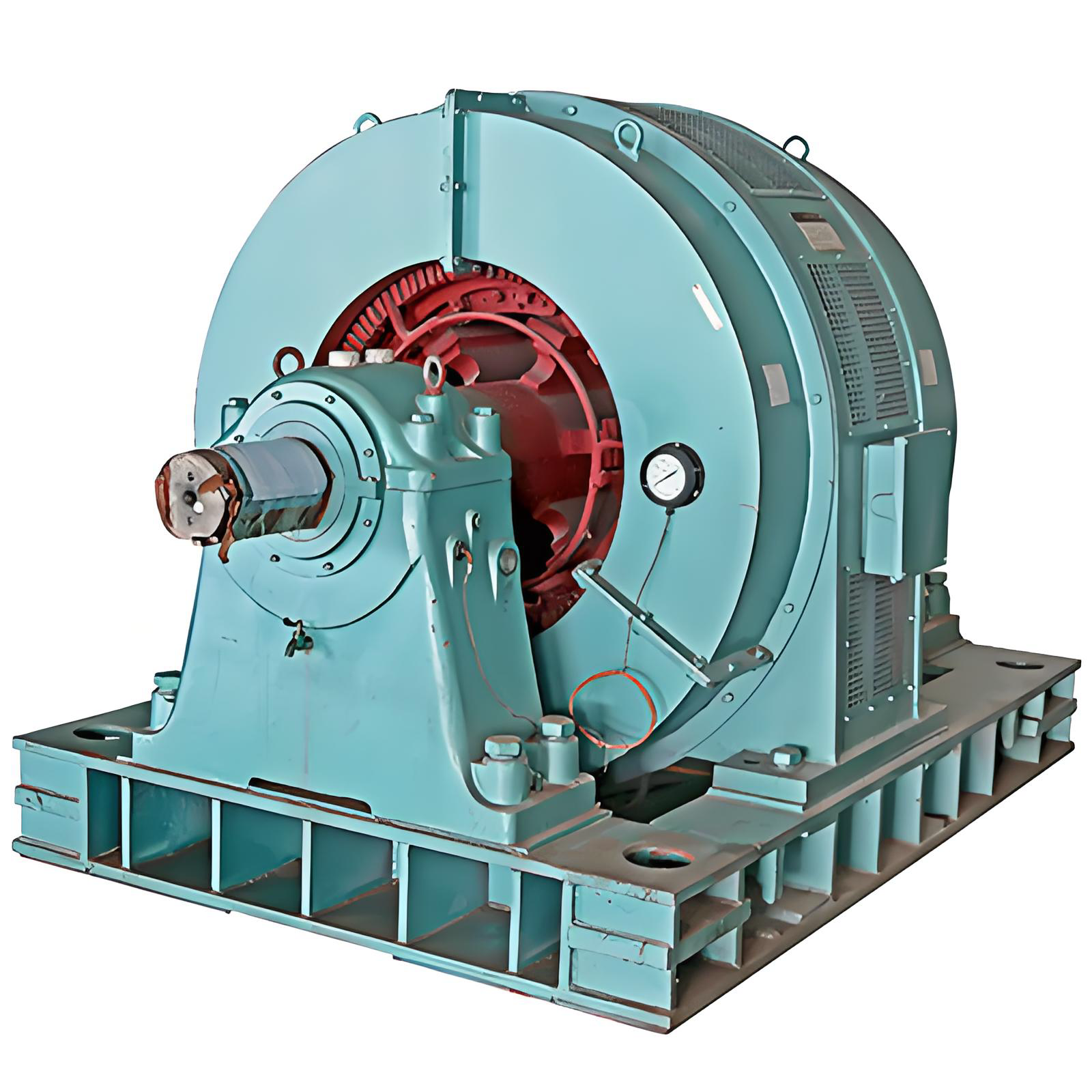

03 Applications & Industry Solutions

1. Heavy Industry Equipment

- Mining and Metallurgy: Hoists, crushers, and rolling mills.

- Производство электроэнергии: Wind turbine yaw systems, hydroelectric monitoring.

- Heavy Machinery: Port cranes, tower crane rotation systems.

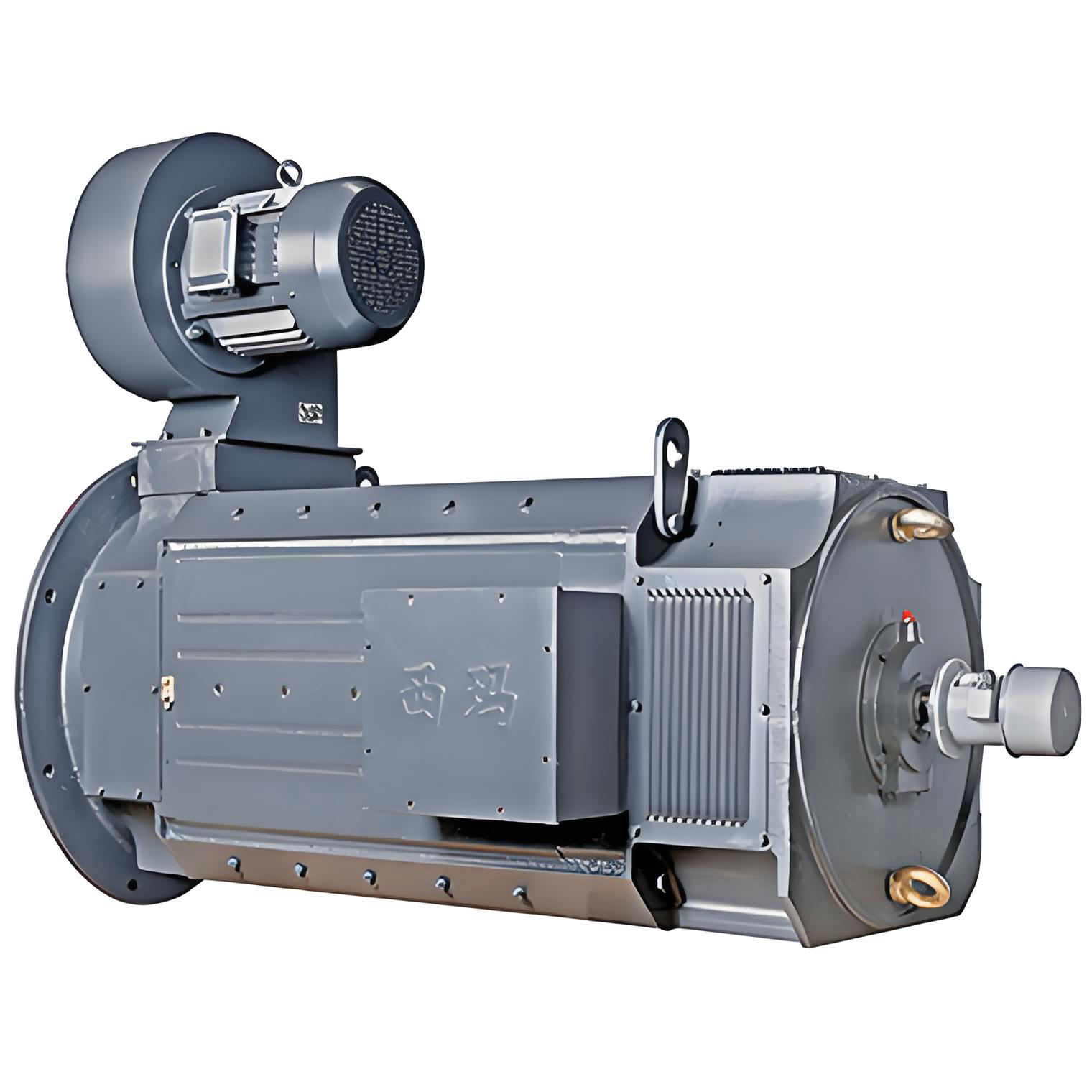

2. High-End Manufacturing & Automation

- Industrial Robotics: Energy and signal transmission in robotic joints.

- Automated Machining Centers: Rotating tables and tool magazine interfaces.

- Precision Instruments: Medical and laboratory rotating equipment.

3. Специализированные среды

- Aerospace: Radar and navigation equipment.

- Marine & Transportation: Shipborne radar, vehicle monitoring systems.

- Harsh Conditions: Dusty, humid, or high-vibration environments.

04 Technical Specifications

| Категория параметров | Specification & Performance |

|---|---|

| Electrical | Rated Voltage: up to 600VAC/DC |

| Rated Current: single circuit up to 10A, power rings up to 600A | |

| Insulation Resistance: ≥1000MΩ@500VDC | |

| Contact Resistance: <10mΩ | |

| Signal Transmission | Supported signals: analog, digital, bus signals |

| Max Transmission Rate: 1Gbps (Ethernet models) | |

| Integrated Power & Signal Capability | |

| Mechanical | Max Rotation Speed: 300–500 RPM |

| Protection Level: IP54–IP65 | |

| Operating Temperature: -30℃ to +80℃ (expandable to -40℃) | |

| Design Life: ≥30 million revolutions | |

| Physical | Housing: Aluminum/ Stainless Steel |

| Contact Material: Precious Metal / Alloy Composite | |

| Wire Specification: High-temp silicone / Teflon wire |

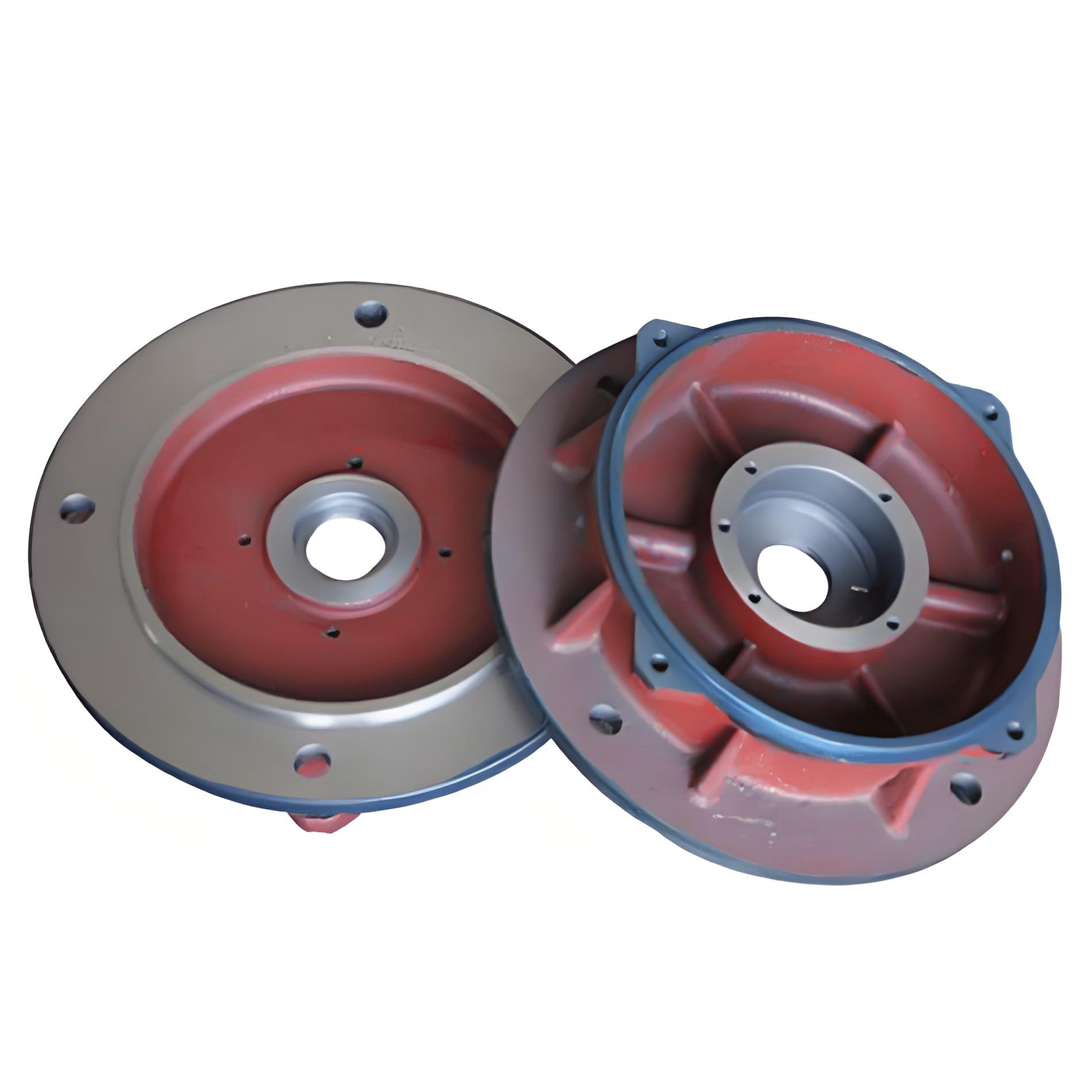

05 Selection & Installation Guide

Selection Considerations

- Electrical Requirements: Total power, voltage, current, and signal types/quantity.

- Mechanical Constraints: Installation space, shaft diameter, weight, and cooling.

- Environmental Factors: Temperature, protection level, vibration, and corrosive conditions.

- Rotation Speed: Select slip ring based on maximum operational speed.

Installation & Maintenance

- Professional Alignment: Ensure concentric installation to avoid eccentric forces.

- Proper Wiring: Follow markings, separate and shield power and signal lines.

- Regular Inspection: Check brushes, contact surfaces, and connections.

- Cleaning: Keep contact surfaces clean to prevent dust accumulation affecting performance.

06 Core Advantages of SIMO Slip Rings

- Proven Technology: Backed by years of Двигатель SIMO manufacturing expertise and rigorous testing.

- Customizable Solutions: Special sizes, interfaces, and combined power-signal options available.

- Обеспечение качества: Full-process quality control from raw materials to finished product.

- Comprehensive Support: Technical consultation, selection guidance, and installation assistance provided.

07 Conclusion

SIMO Motor slip rings are essential rotating electrical components, offering high efficiency, reliable performance, and long-lasting durability. With wide application adaptability, they serve as a critical solution for industrial machinery, automated systems, and precision equipment.

Whether upgrading traditional industrial machinery or developing advanced intelligent equipment, choosing SIMO Motor slip rings enhances operational performance and reliability, providing a professional solution for power and signal transmission in rotating systems.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206