摘要:

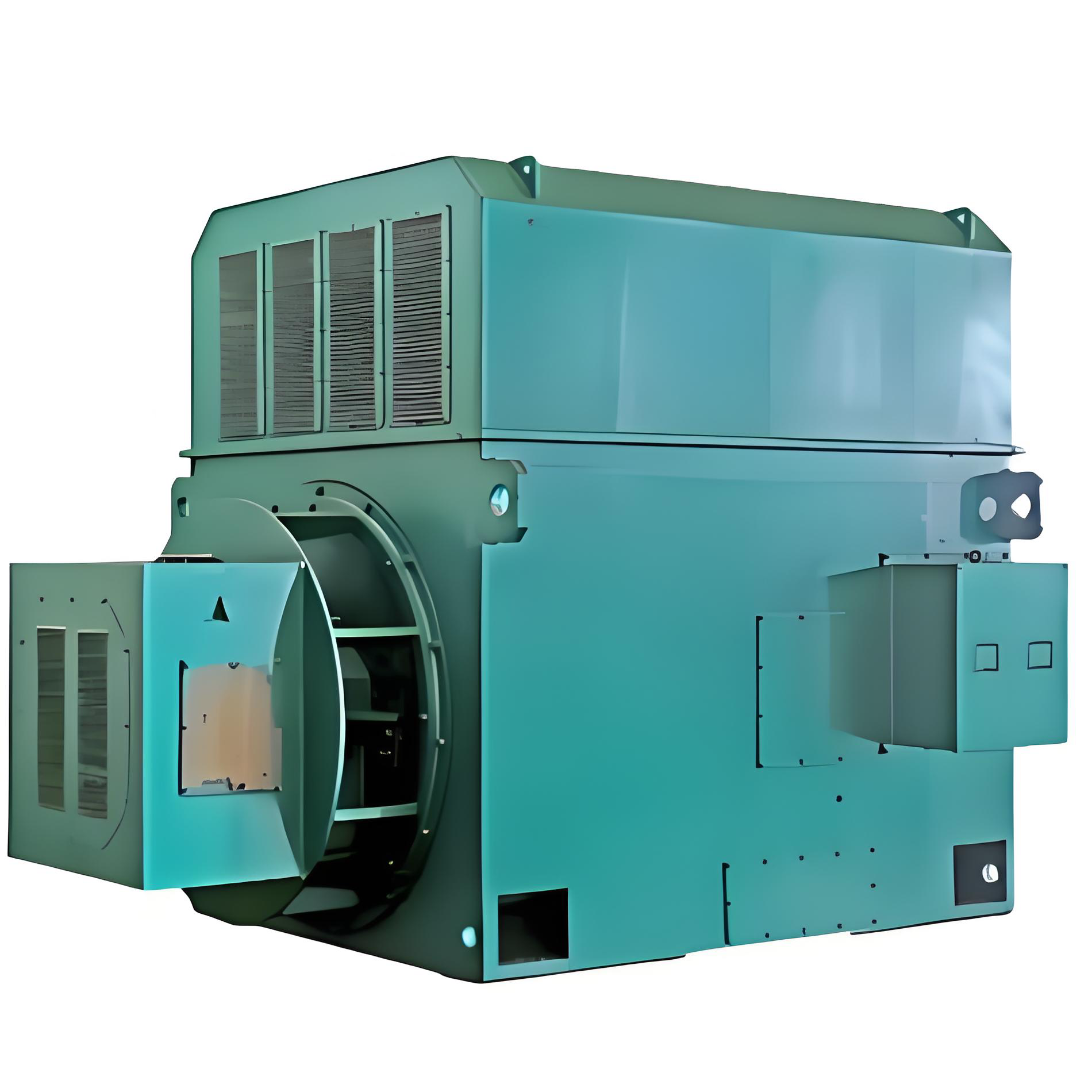

The SIMO YRKK series high voltage wound rotor three-phase asynchronous motor is designed for demanding industrial applications. With advanced technology, it delivers high performance, reliability, and energy efficiency. Ideal for power plants, mining, and heavy machinery where high torque and reliability are required.

Xi’an Taifu Simo Motor YRKK Series High Voltage Wound Rotor Three-Phase Motor assíncrono – Professional Guide

Advanced Wound Rotor Technology Combined with Air-to-Air Cooling for Reliable Power in Heavy-Duty Industrial Applications

O Xi’an Taifu Simo Motor YRKK Series (H355–1000) High Voltage Wound Rotor Three-Phase Asynchronous Motor is a high-performance power solution specifically engineered for demanding industrial environments. This series integrates innovative wound rotor technology with an efficient air-to-air cooling system, delivering excellent starting characteristics, stable operation, and long-term reliability. It is an ideal drive solution for heavy-load industrial equipment across multiple industries.

Product Model Identification – Accurate Specification Recognition

O Simo Motor YRKK series adopts a standardized model naming system. Taking YRKK3551-4 as an example:

- “YRKK” designation: Enclosed wound rotor asynchronous motor with air-to-air heat exchanger

- “3551” code:

- “355” indicates a frame center height of 355 mm

- “1” represents core length No.1

- “4” poles: Indicates a 4-pole motor configuration

This naming system strictly complies with IEC standards, allowing users to quickly and accurately identify key motor parameters and select the correct model for their application.

Technical Overview – Professional Design for Diverse Industrial Needs

Core Technical Features

O YRKK series 6 kV and 10 kV wound rotor three-phase asynchronous motors feature advanced rotor winding technology, protection classes IP44 or IP54, and an IC611 air-to-air cooling system. These motors combine high efficiency, energy saving, low noise, low vibration, and compact structure, ensuring reliable performance and easy maintenance in continuous-duty operations.

Outstanding Performance Advantages

The YRKK series delivers excellent starting performance, providing high starting torque with relatively low starting current, making it especially suitable for:

- Power grids with limited capacity where squirrel cage motors cannot start reliably

- Heavy-duty equipment requiring frequent starts or long starting times

- Applications requiring speed regulation within a certain range

- Special drives such as heavy-duty hoists, rolling mills, and wire drawing machines

Wide Range of Applications

Thanks to its superior performance, the Simo Motor YRKK series is widely used in:

- Heavy machinery: Rolling mills, crushers, grinding mills

- Material handling equipment: Winches, hoists, elevators, conveyor systems

- Manufacturing equipment: Wire drawing machines, extrusion presses, large machine tools

- Mining and metallurgical equipment: Mine hoists, smelting and refining systems

Standard Technical Specifications

- Protection class: IP44 or IP54 (GB4942.1 compliant)

- Cooling method: IC611 (GB/T1993 compliant)

- Mounting arrangement: IMB3 (GB997 compliant)

- Duty type: Continuous duty based on S1 rating

- Rated frequency: 50 Hz

- Rated voltage: 6 kV, 10 kV (other voltages available on request)

- Insulation class: Class F

- Bearing system: IP54-designed bearings with grease lubrication, supporting online grease filling and draining

Core Technical Strengths – The Foundation of Superior Quality

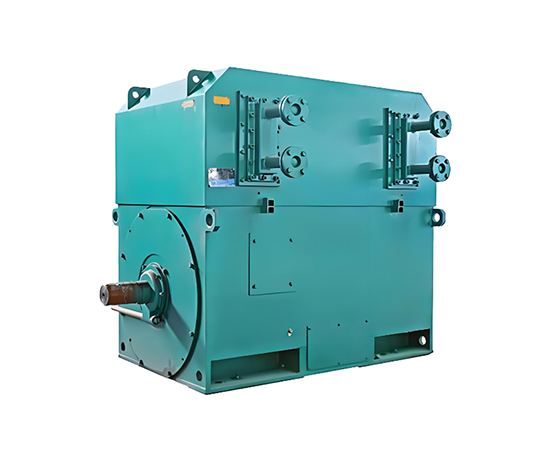

Innovative Wound Rotor Design

The YRKK series uses advanced wound rotor technology with external resistors or liquid resistance starters, enabling smooth starting and effective speed control. Compared with conventional squirrel cage motors, this design significantly reduces grid impact and is ideal for applications with limited power supply capacity.

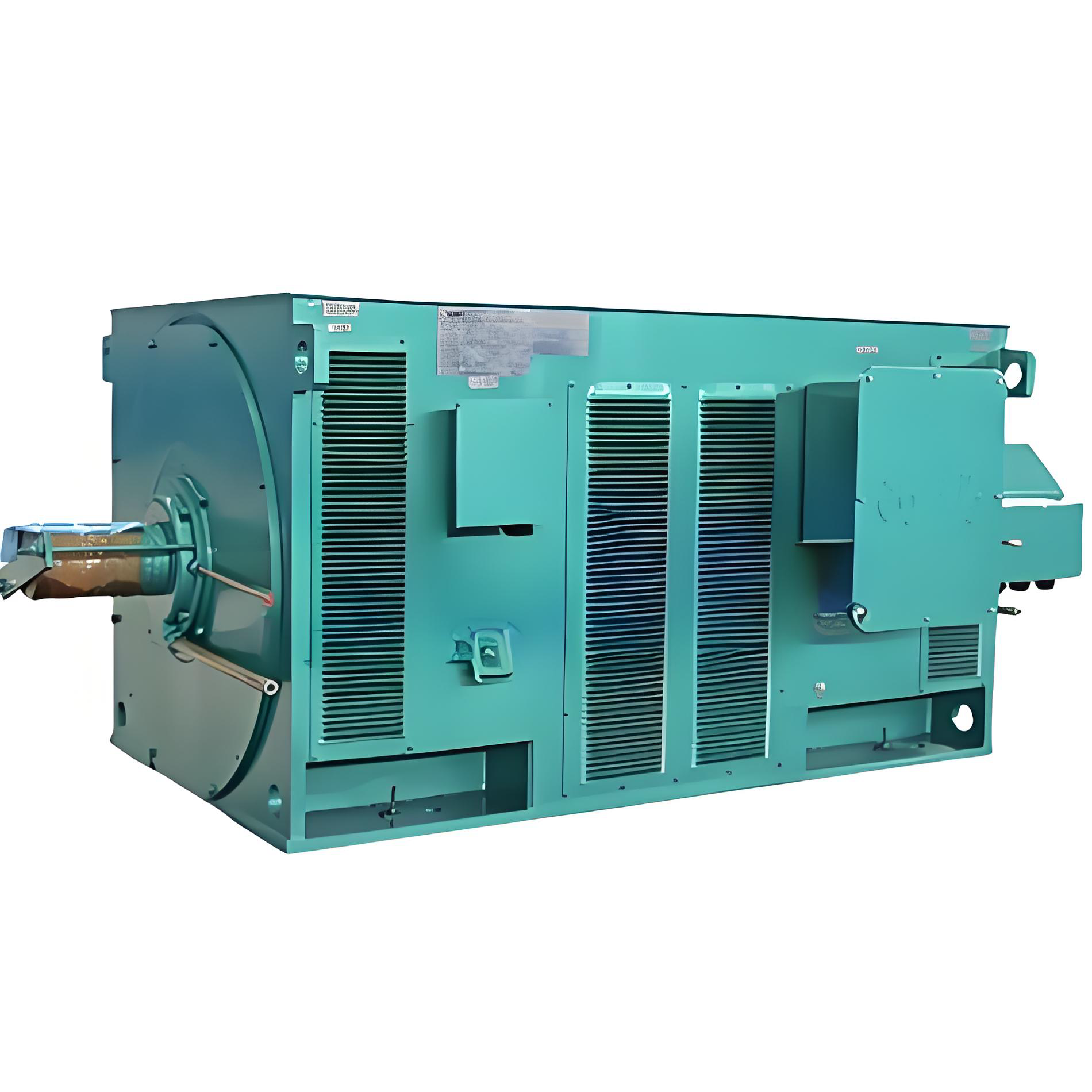

Efficient Air-to-Air Cooling System

Equipped with an IC611 cooling system, the motor uses a high-efficiency air-to-air heat exchanger to maintain optimal operating temperatures under continuous heavy-load conditions. This design enhances reliability, extends insulation life, and ensures stable performance in harsh industrial environments.

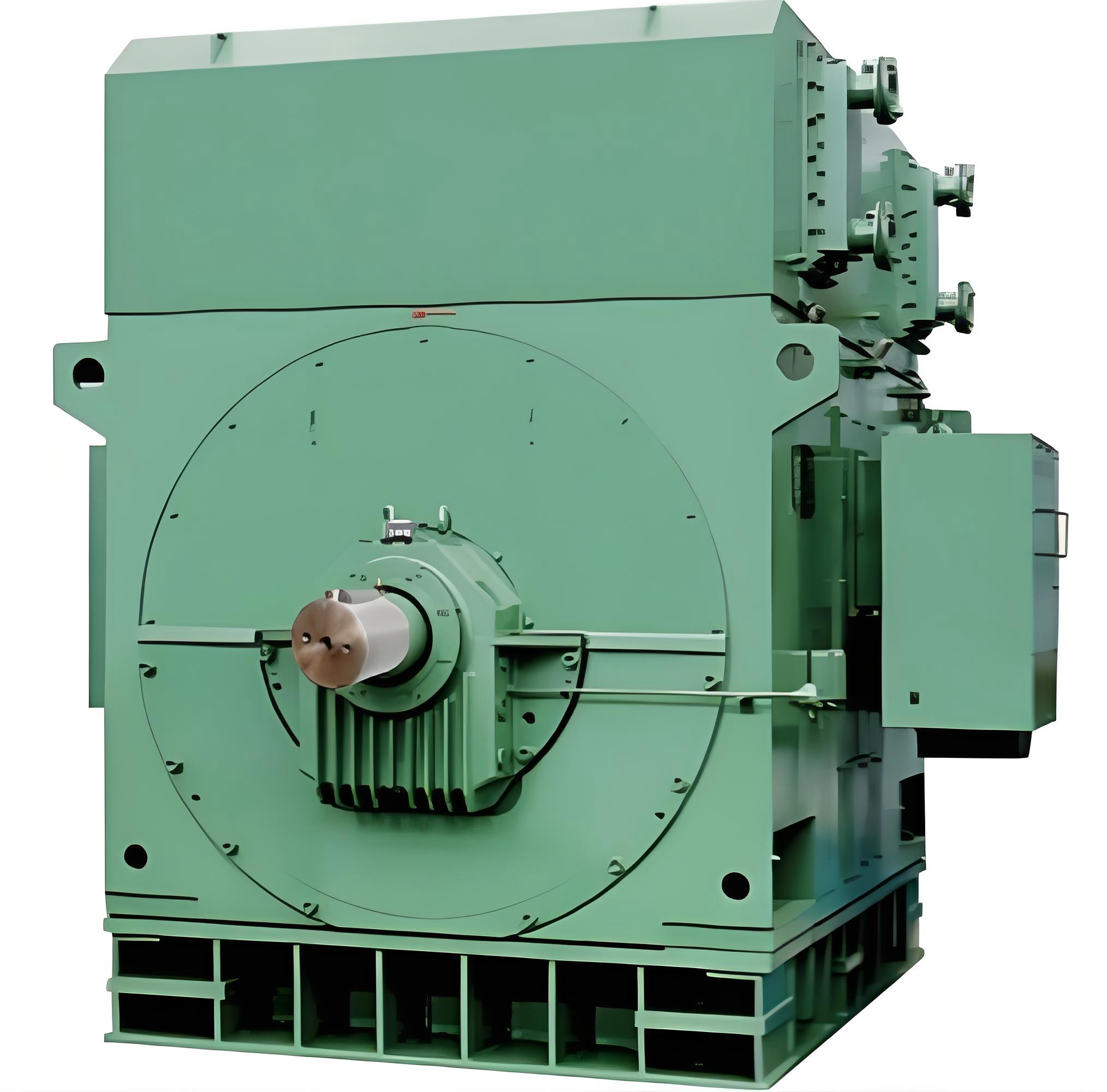

Optimized Mechanical Structure

The frame and end covers are manufactured from high-strength materials and feature precision structural design. After strict dynamic balancing tests, the motor runs smoothly with minimal vibration, allowing it to withstand heavy load shocks and demanding operating conditions for long-term stable operation.

Reliable Insulation System

The stator windings adopt Class F insulation, treated with anti-corona measures and processed using VPI (Vacuum Pressure Impregnation) technology. This provides excellent resistance to moisture, corrosion, and high temperatures, ensuring reliable insulation performance even in harsh environments.

Simo Motor Comprehensive Quality Assurance System

Corporate Strength

Simo Motor Group Co., Ltd. is a backbone enterprise in China’s motor manufacturing industry, specializing in the R&D and production of large and medium-sized high- and low-voltage AC and DC motors. The company operates a complete industrial chain covering motor design and manufacturing, electrical control, machining, mold making, casting, and logistics, providing customers with integrated power system solutions.

Certifications and Honors

- Quality management: ISO9001 certification

- Environmental and safety management: ISO14000 and OHSAS18000 certifications

- International product certifications: CE (EU), UL (USA), CCC (China)

- Industry recognition: China Machinery Industry Top 500, Top 100 Electrical Industry Enterprises

- Quality honors: AAA Credit Enterprise, Provincial and Municipal Famous Brand Products, “China Light of Fame” Brand

Strict Quality Commitment

- Strict standards: Manufactured and inspected according to national and international standards; non-conforming products are never released

- Comprehensive testing: Each motor undergoes 72-hour continuous operation testing after final assembly

- On-time delivery: Products delivered strictly according to contract terms, with early delivery available upon agreement

- Responsive after-sales service: Customer issues responded to within 24 hours, on-site service initiated within 48 hours

- Warranty policy: Three-guarantee service for qualidade issues, with return or replacement if repair fails to meet factory standards

- Lifetime support: Lifetime cost-price maintenance service after sale

Ordering Guide and Technical Parameters

Standard Configuration Example

| Parameter | Specification |

|---|---|

| Motor model | YRKK3551-4 |

| Mounting type | IMB3 |

| Rated power | 185 kW |

| Protection class | IP44 or IP54 |

| Rated voltage | 6 kV |

| Cooling method | IC611 |

| Rated frequency | 50 Hz |

| Insulation class | Class F |

| Synchronous speed | 1500 r/min |

| Ambient conditions | Altitude ≤1000 m, ambient temperature 40°C |

Important Notes

Technical Standards

- Power ratings and installation dimensions comply with IEC standards

- Protection class complies with GB4942.1

- Cooling method complies with GB/T1993

- Mounting arrangement complies with GB997

Standard Ordering Procedure

- Refer to the product catalog to confirm the required model and specifications

- Priority is given to standard models to reduce cost and delivery time

- Clearly specify motor model, power, voltage, frequency, and other key parameters in the contract

- If noise level is not specified, motors are supplied according to Grade 2 by default

Customization Options

- Special requirements must be clearly stated in the contract

- Custom options include double shaft extension, special terminal box position, reverse rotation, and more

- Special versions available for humid tropics, outdoor anti-corrosion environments

- All customized requirements must be confirmed with the factory technical department in advance

Professional Selection Recommendations

When selecting a YRKK series high voltage wound rotor motor, consider the following factors:

- Load characteristics: load type, starting frequency, inertia, and speed regulation requirements

- Power grid conditions: voltage level, grid capacity, voltage fluctuation range

- Operating environment: temperature, humidity, altitude, dust concentration

- Installation constraints: available space and ventilation conditions

- Maintenance requirements: expected maintenance cycle and ease of servicing

For applications requiring high starting torque, limited grid capacity, or adjustable speed range, the Simo Motor YRKK series wound rotor motor is a superior choice compared with conventional squirrel cage motors.

Conclusão

O Xi’an Taifu Simo Motor YRKK Series (H355–1000) High Voltage Wound Rotor Three-Phase Asynchronous Motor stands out as an ideal power solution for heavy-duty industrial applications, thanks to its innovative design, outstanding performance, and reliable quality. Backed by strong technical expertise and a comprehensive service system, Motor Juca provides professional technical support and dependable after-sales service for every customer.

For detailed technical information or customized motor selection support, please contact the Simo Motor professional technical team for comprehensive assistance.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206