摘要:

The YQ series low voltage asynchronous motor is designed for industrial applications requiring stable performance, compact structure, and reliable operation. It features good starting performance and durability, making it suitable for machinery such as pumps, fans, compressors, and general industrial equipment.

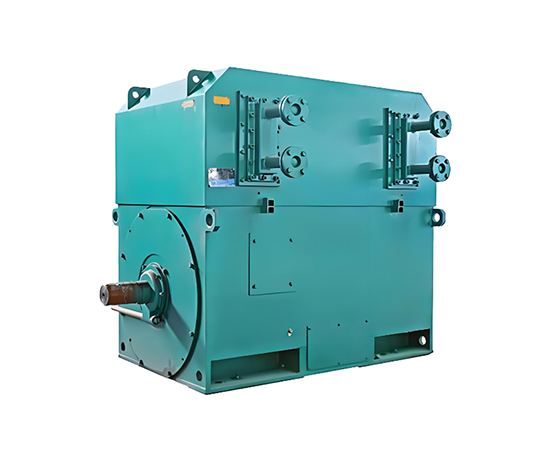

YQ Series Low-Voltage Motor assíncronos: High-Efficiency and Reliable Industrial Power Solution

Product Overview

O YQ Series Low-Voltage Asynchronous Motor is a three-phase asynchronous motor designed with advanced electromagnetic engineering and premium materials. It features a simple yet robust structure, reliable operation, and easy maintenance. This series strictly complies with IEC international standards, with power ratings and mounting dimensions aligned with global standards, allowing seamless integration and replacement in industrial equipment.

As a core industrial power source, the YQ series drives various machinery, including fans, pumps, compressors, crushers, and material handling systems. Its totally enclosed fan-cooled (TEFC) structure ensures dependable operation in diverse environmental conditions, making it ideal for mining, chemical, metallurgy, power generation, and other industrial sectors.

Key Technical Features

1. High-Efficiency and Energy-Saving Design

- Optimized electromagnetic design and low-loss materials boost efficiency, reaching over 93%.

- Compared with conventional motors, energy consumption is significantly reduced, lowering operating costs and shortening payback periods.

2. Exceptional Operational Performance

- Wide Speed Range: Adjustable from 0–180Hz to meet varying operational needs.

- High Starting Torque: Capable of reaching 200% of rated torque for heavy-load starts.

- Low Vibration & Noise: Dynamic balancing and optimized structural design ensure smooth, quiet operation.

3. Robust Structural Design

- High Protection: IP55-rated housing prevents dust and moisture ingress.

- Premium Insulation: F-class or H-class insulation ensures durability and long service life.

- Enhanced Bearings: Low-vibration, low-noise bearings provide reliable, long-term operation.

Technical Parameters

| Parameter | Specification |

|---|---|

| Tensão nominal | 380V |

| Frequência nominal | 50Hz |

| Protection Level | IP55 |

| Classe de isolamento | F / H |

| Método de resfriamento | IC411 (TEFC) |

| Duty | S1 (Continuous) |

| Mounting | IMB3, IMB5, IMB35 |

Performance Highlights:

- Maintains high efficiency across a wide load range.

- Stable operation under fluctuating voltage conditions.

- High power factor improves grid qualidade and reduces reactive power compensation needs.

Structural Design and Configuration

1. Motor Body

- Frame: High-strength material for mechanical stress resistance.

- Stator: High-grade insulated windings with long-term reliability.

- Rotor: Precision-manufactured rotor ensures excellent dynamic balance and smooth operation.

2. Cooling System

- TEFC Design: Totally enclosed fan-cooled structure provides effective heat dissipation.

- Optimized Airflow: Engineered airflow channels maximize cooling and prevent overheating.

Applications

Industrial Drives:

- Fans & Pumps: Suitable for blowers, ventilators, and industrial pumps.

- Compressors: Powers air compressors and other gas compression systems.

- Material Handling: Drives conveyors, belt systems, and other continuous-operation equipment.

Special Applications:

- Rail Transit: Core power unit for light rail vehicles in harsh environments.

- Mining Machinery: Reliable drive for crushers, coal mills, and heavy-duty equipment.

- Agricultural Irrigation: Powers submersible axial-flow pumps for irrigation systems.

Advantages and Value

1. Operational Reliability

- Optimized mechanical design resists mechanical and thermal stresses.

- High-quality materials and precision manufacturing ensure long-term stability.

- High protection level and premium insulation maintain reliability in harsh conditions.

2. Energy Efficiency and Economic Benefits

- Reduces operating costs with high efficiency.

- High power factor improves energy utilization and grid stability.

- Low lifecycle cost due to long service life and minimal maintenance.

3. Conveniência de manutenção

- Accessible design allows easy inspection and maintenance.

- Modular components reduce spare parts inventory and simplify servicing.

- Premium insulation extends service life and maintenance intervals.

Installation and Operation

Environmental Requirements:

- Ambient temperature up to 40°C.

- Maximum altitude: 1000m.

- Relative humidity within standard limits; clean, non-corrosive environment.

Installation & Commissioning:

- Firm, level foundation to support motor weight and operational stresses.

- Precise alignment with driven equipment via couplings.

- Correct electrical connections according to motor nameplate and wiring diagrams; proper grounding is essential.

Service and Technical Support

Quality Assurance:

- Manufactured in strict compliance with IEC and national standards.

- Multiple performance tests ensure reliability and compliance.

- Each motor undergoes comprehensive factory testing.

After-Sales Service:

- Professional technical support for selection, installation, and operation.

- Rapid response: service personnel dispatched within 48 hours of request.

- Long-term technical and maintenance support provided.

O YQ Series Low-Voltage Asynchronous Motor combines advanced engineering, high efficiency, and reliable performance, making it an ideal solution for industrial power applications.

Choosing YQ series motors ensures dependable performance, energy efficiency, and comprehensive technical support, driving industrial productivity and sustainable development.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206