摘要:

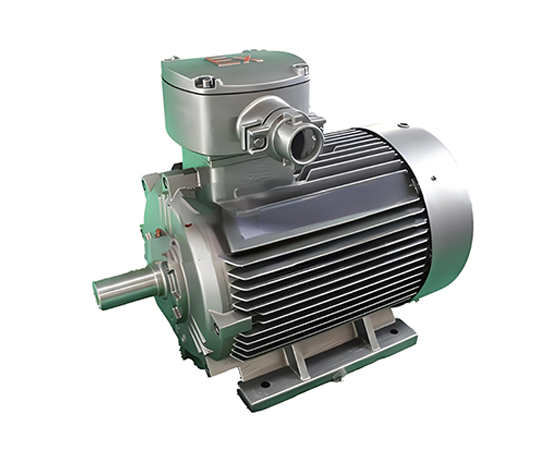

The SIMO YTP series railway-specific motor is designed for use in locomotives, railcars, and other railway applications. It provides reliable performance, high efficiency, and robust durability to meet the demanding conditions of railway operations.

SIMO YTP Railway-Specific Motor: Dedicated Power Solution for Locomotives

In the railway transport sector, the SIMO YTP series railway-specific motor delivers exceptional stability and environmental adaptability, serving as the core power source for auxiliary systems in both diesel and electric locomotives.

Designed specifically for locomotives, the YTP series is a high-efficiency AC motor manufactured in strict compliance with TB/T 1608 "Basic Technical Requirements for Three-Phase Motor assíncronos for Locomotives and Rolling Stock" and other railway industry standards. Advanced electromagnetic design and optimized mechanical structure allow reliable operation under extreme conditions, providing consistent power support for all locomotive auxiliary equipment.

As SIMO Motor’s specialized railway product, the YTP series integrates innovative cooling technology and optimized material selection, offering robust construction, high efficiency, stable operation, and easy maintenance. It is widely used to drive hydraulic pumps, blowers, axial fans, cooling fans, air compressors, and other auxiliary mechanical systems on diesel locomotives, electric locomotives, and EMUs.

I. Visão geral do produto e principais recursos

1. Introdução ao produto

O SIMO YTP railway-specific motor is a three-phase asynchronous motor series designed for locomotive operating conditions. Its modular design allows flexible configuration to meet the diverse power demands of auxiliary equipment.

These motors are the core power source for hydraulic pumps, blowers, axial fans, cooling fans, air compressors, and other auxiliary mechanical drives, ensuring reliable and stable operation of locomotive auxiliary systems.

2. Principais vantagens técnicas

- Exceptional Environmental Adaptability: Operates reliably under locomotive vibrations and shocks, maintaining performance in rain, snow, wind, and dust conditions.

- Optimized Temperature Range: Suitable for ambient temperatures of -15°C to +40°C.

- High Altitude Compatibility: Operates effectively at altitudes up to 1,000 meters.

- Excellent Protection: IP44, IP54, or IP55 protection prevents dust, moisture, and contaminants from entering the motor.

II. Technical Parameters and Performance Specifications

| Categoria de parâmetro | Especificações e indicadores de desempenho |

|---|---|

| Tamanho da estrutura | H80–H200 |

| Potência nominal | 0.55kW–30kW |

| Tensão nominal | 380V (customizable) |

| Frequência nominal | 50Hz (customizable) |

| Duty Type | S1 or S4 |

| Classe de proteção | IP44, IP54, IP55 |

| Método de resfriamento | IC01 |

| Tipo de montagem | IMB3, IMB35, IMV1 |

| Classe de isolamento | Railway standard compliant |

Destaques de desempenho

- High Efficiency: Optimized electromagnetic design and low-loss materials ensure high efficiency across varying loads.

- Alto torque de partida: Special rotor design supports start-up of fans, pumps, and similar loads.

- Wide Voltage Tolerance: Maintains stable performance under locomotive power supply variations.

III. Projeto e configuração estrutural

1. Estrutura principal do motor

- Moldura: High-strength cast iron or aluminum, engineered for durability under vibration and shock.

- End Caps and Bearings: Precision bearing selection and optimized end-cap design ensure long-term reliability.

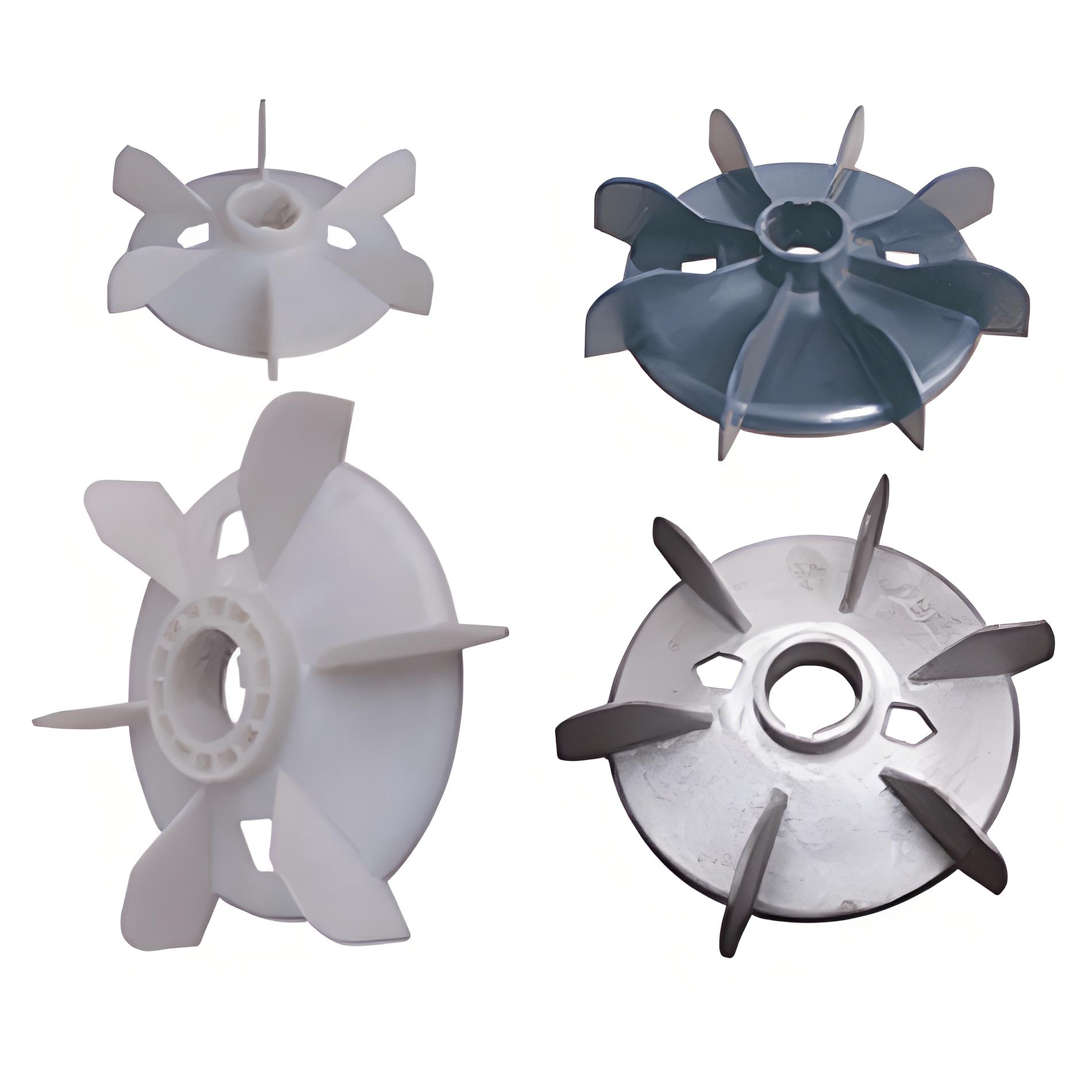

- Cooling Design: Optimized airflow channels and heat fins maintain stable operating temperatures.

2. Insulation and Protection

- Insulation System: High-temperature resistant materials and advanced processing ensure reliable insulation in harsh conditions.

- Sealing: Efficient shaft seals and joint seals prevent lubricant leaks and contamination.

- Surface Treatment: Corrosion-resistant coating and anti-rust treatment protect against moisture, salt, and other harsh environments.

IV. Applications and Use Cases

1. Primary Auxiliary Equipment

- Ventilation Systems: Drives blowers and axial fans for locomotive engine and electrical compartments.

- Cooling Systems: Powers cooling fans for converters, traction motors, and other critical devices.

- Air Brake Systems: Drives air compressors to supply reliable braking air.

- Hydraulic Systems: Powers hydraulic pumps for locomotive hydraulic systems.

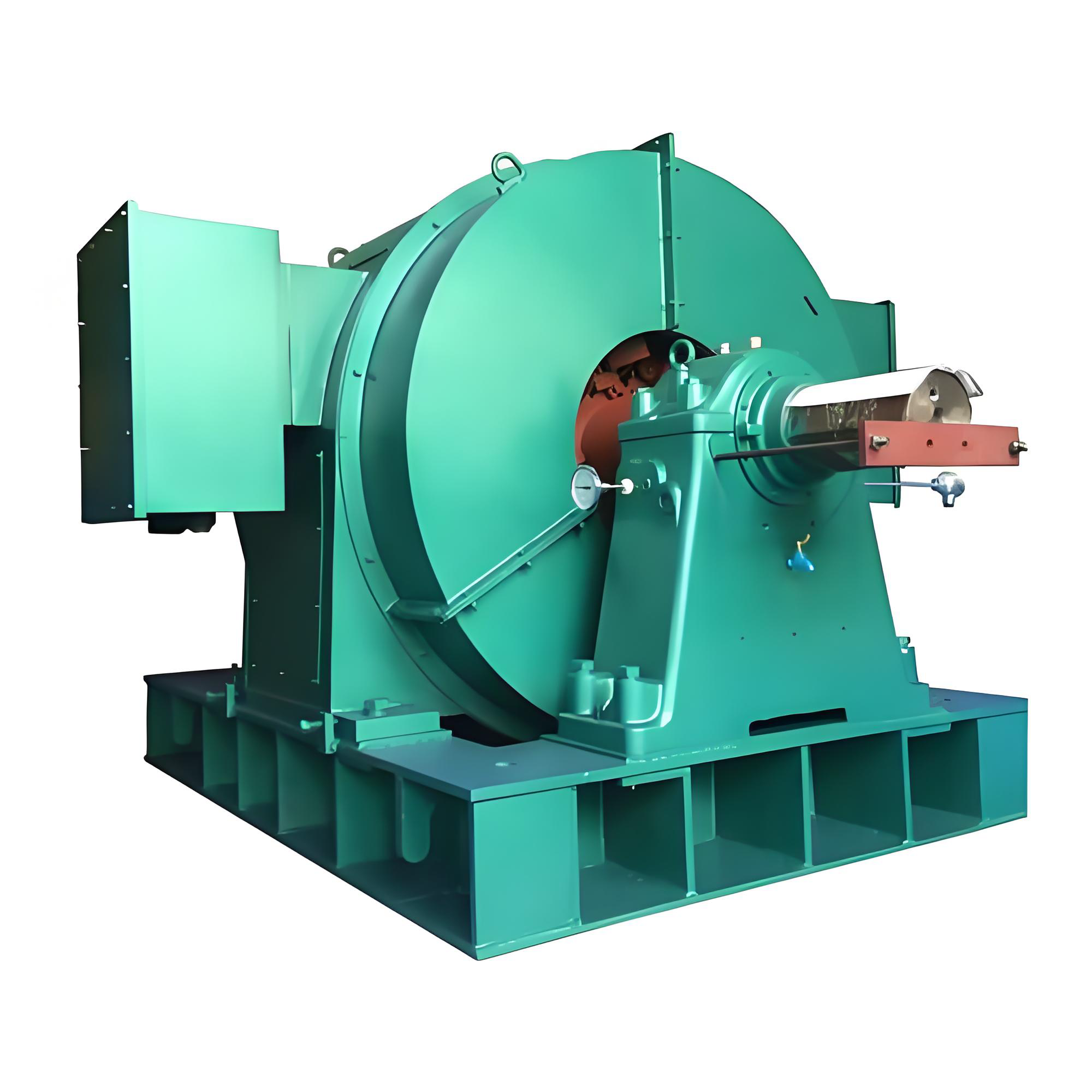

2. Applicable Locomotive Types

- Diesel Locomotives: Provides power for all auxiliary equipment.

- Electric Locomotives: Supports electric locomotive auxiliary systems.

- EMU Trains: Delivers reliable power to auxiliary systems.

V. Vantagens e valor

1. High Reliability

- Robust Design: Optimized mechanical structure withstands locomotive shocks and vibration.

- High-Quality Materials: Critical components resist wear and corrosion for extended lifespan.

- Strict Quality Control: Full-process monitoring ensures compliance with railway standards.

2. Maintenance Convenience

- Modular Design: Reduces maintenance complexity and spare parts inventory.

- Easy Inspection & Repair: Structure facilitates routine maintenance and troubleshooting.

- Comprehensive Support: Fast technical service ensures prompt fault resolution.

3. Energy Efficiency

- Optimized Electromagnetic Design: Reduces iron and copper losses, improving operational efficiency.

- Proper Power Matching: Multiple power options prevent over-sizing and energy waste.

- Optimized Performance Curves: Maintains high efficiency across typical load ranges.

VI. Diretrizes de instalação e operação

- Environmental Requirements: Altitude ≤1000m, temperature -15°C to +40°C.

- Humidity: Average monthly humidity ≤90% at 25°C.

- Special Environmental Adaptation: Protection against rain, snow, wind, and dust.

- Electrical Connection: Correct voltage, frequency, and grounding; appropriate protection devices for overload, overcurrent, and phase loss.

VII. Serviço e suporte técnico

- Controle de qualidade: ISO9001 certified; select products CE and CCC certified.

- Strict Testing: Includes no-load, full-load, and insulation withstand tests.

- Serviço pós-venda: 24-hour response; on-site service within 48 hours.

- Lifetime Support: Long-term technical assistance and warranty coverage.

Ordering Notes

- Specify model, power, voltage, speed, duty type, and mounting configuration.

- Clearly state any special requirements.

- Include export-specific requirements if needed.

O SIMO YTP railway-specific motor provides reliable, durable, and energy-efficient power for locomotive auxiliary systems, making it the preferred choice in railway applications. Selecting SIMO YTP ensures stable operation, technical support, and long-term service, advancing railway technology and efficiency.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206