摘要:

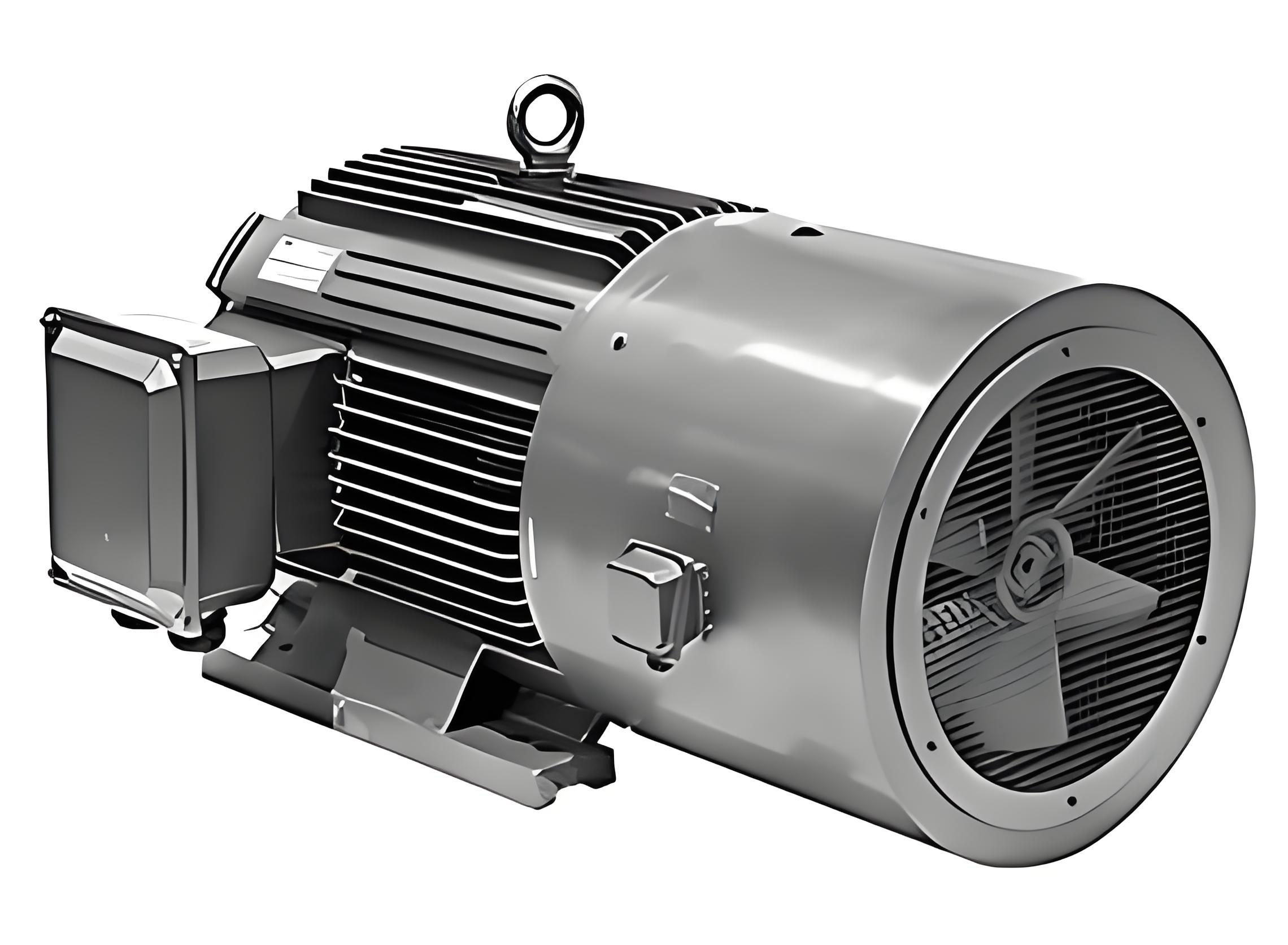

The TDMK36 extra-large synchronous motor is designed for heavy industrial applications requiring extremely high power and precise synchronous operation. With robust construction, high efficiency, and stable performance, it is ideal for power plants, large-scale machinery, and demanding industrial environments.

SIMO TDMK 36-Pole Extra-Large Motor síncrono: Professional Power Solution for Mining Mill Drives

O SIMO TDMK 36-pole extra-large synchronous motor is specifically designed for the mining and material grinding industry, providing a reliable and efficient power source for heavy-duty equipment such as ball mills and rod mills.

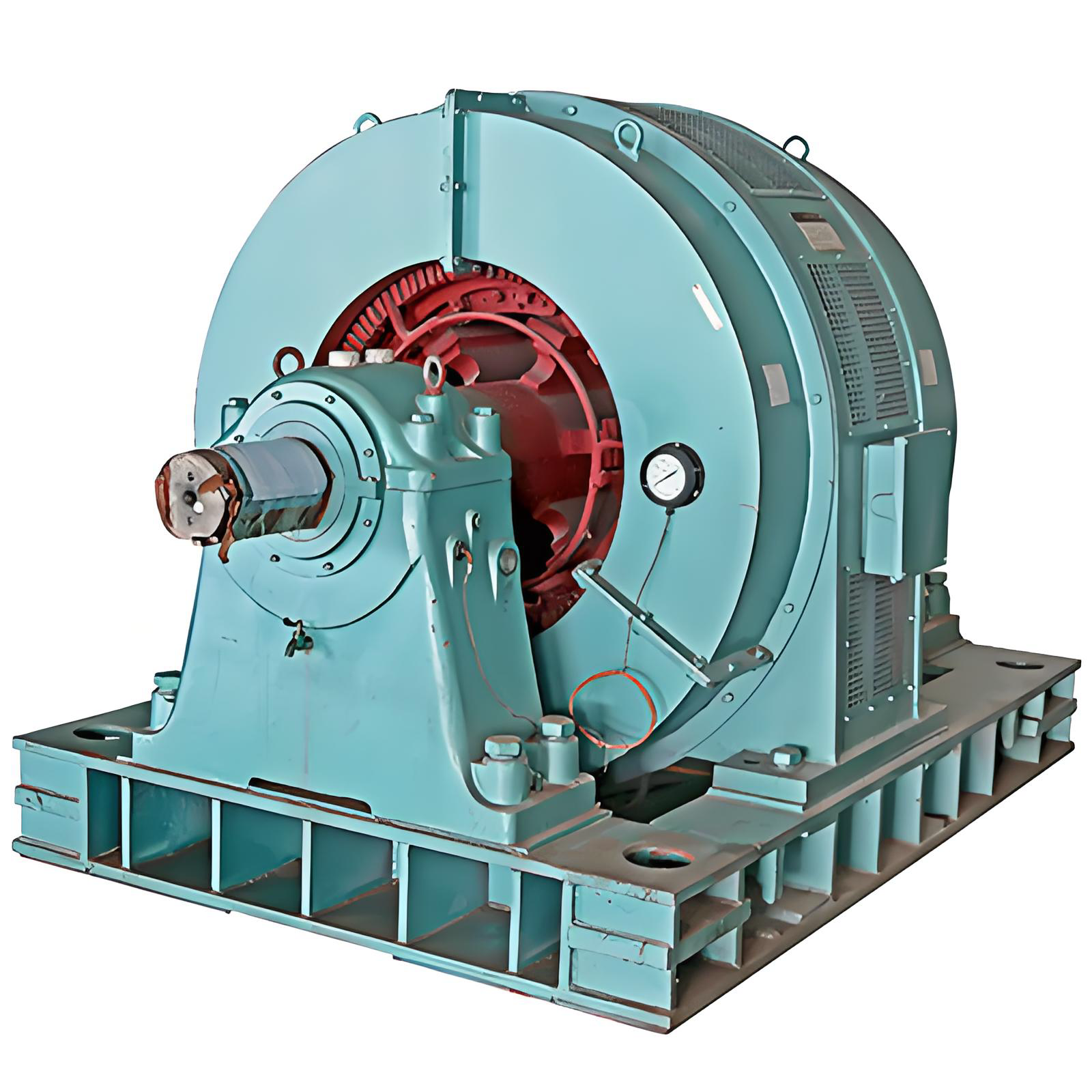

Manufactured by Motor SIMO, the TDMK36 combines advanced motor design with precision manufacturing. Optimized electromagnetic design and robust mechanical structure ensure high-efficiency, stable operation for various mining mill applications. The motor is designed according to GB755 "Basic Technical Requirements for Rotating Electrical Machines" e JB/T1473-2000 "Technical Conditions for Large Three-Phase AC Synchronous Motors for Mining Mills", guaranteeing reliable performance under harsh mining conditions.

I. Visão geral do produto e principais recursos

1. Introdução ao produto

O TDMK36-pole synchronous motor is engineered for mining mill applications. Its 36-pole design delivers high torque at low speeds, perfectly matching the power requirements of ball mills, rod mills, and other heavy-duty grinding equipment.

Key characteristics include high efficiency, low temperature rise, minimal vibration, and high starting torque, making it ideal for continuous operation under heavy load and harsh conditions.

2. Core Technical Features

- Superior Starting Performance: Supports full-voltage direct start; reduced-voltage or soft start options available for limited grid capacity, reducing starting current and torque proportionally.

- Robust Structural Design: Welded steel frame and high-strength rotor ensure long-term reliability under heavy loads.

- Advanced Insulation System: Stator windings use molded double-layer short-pitch coils with B-class or F-class insulation. Vacuum pressure impregnation ensures mechanical strength, excellent moisture resistance, and long life.

- Flexible Voltage Adaptation: Standard 6 kV, optional 3 kV or 10 kV, voltage deviation ±5%.

II. Technical Parameters and Performance Specifications

1. Basic Technical Parameters

| Parameter | Specification |

|---|---|

| Potência nominal | 400 kW – 1600 kW (customizable) |

| Poles | 36 |

| Tensão nominal | 6 kV, 10 kV (optional 3 kV) |

| Frequency | 50 Hz |

| Power Factor | 0.9 (leading) |

| Rated Speed | 167 r/min (36 poles, 50 Hz) |

| Classe de proteção | IP00, IP20, IP21, IP23, IP44 (customizable) |

| Classe de isolamento | F-class or B-class |

| Método de resfriamento | IC01, IC27, IC37, IC81W, IC91W (customizable) |

2. Typical Model Performance

| Model | Rated Power (kW) | Voltage (kV) | Current (A) | Speed (r/min) | Power Factor | Locked Rotor Current / Rated Current | Pull-in Torque / Rated Torque | Weight (t) |

|---|---|---|---|---|---|---|---|---|

| TDMK500-36 | 500 | 6 | 581 | 167 | 0.96 | 2.7 | 1.04 | 12.7 |

| TDMK630-36 | 630 | 6 | 741 | 167 | 0.96 | 3.1 | 1.02 | 13.5 |

| TDMK800-36 | 800 | 6 | 931 | 167 | 0.95 | 5.9 | 1.01 | 16.0 |

| TDMK1000-36 | 1000 | 6 | 115 | 167 | 0.96 | 1.0 | 1.01 | 16.0 |

| TDMK1600-36 | 1600 | 6 | 181 | 167 | 0.96 | 1.19 | 1.19 | 31.0 |

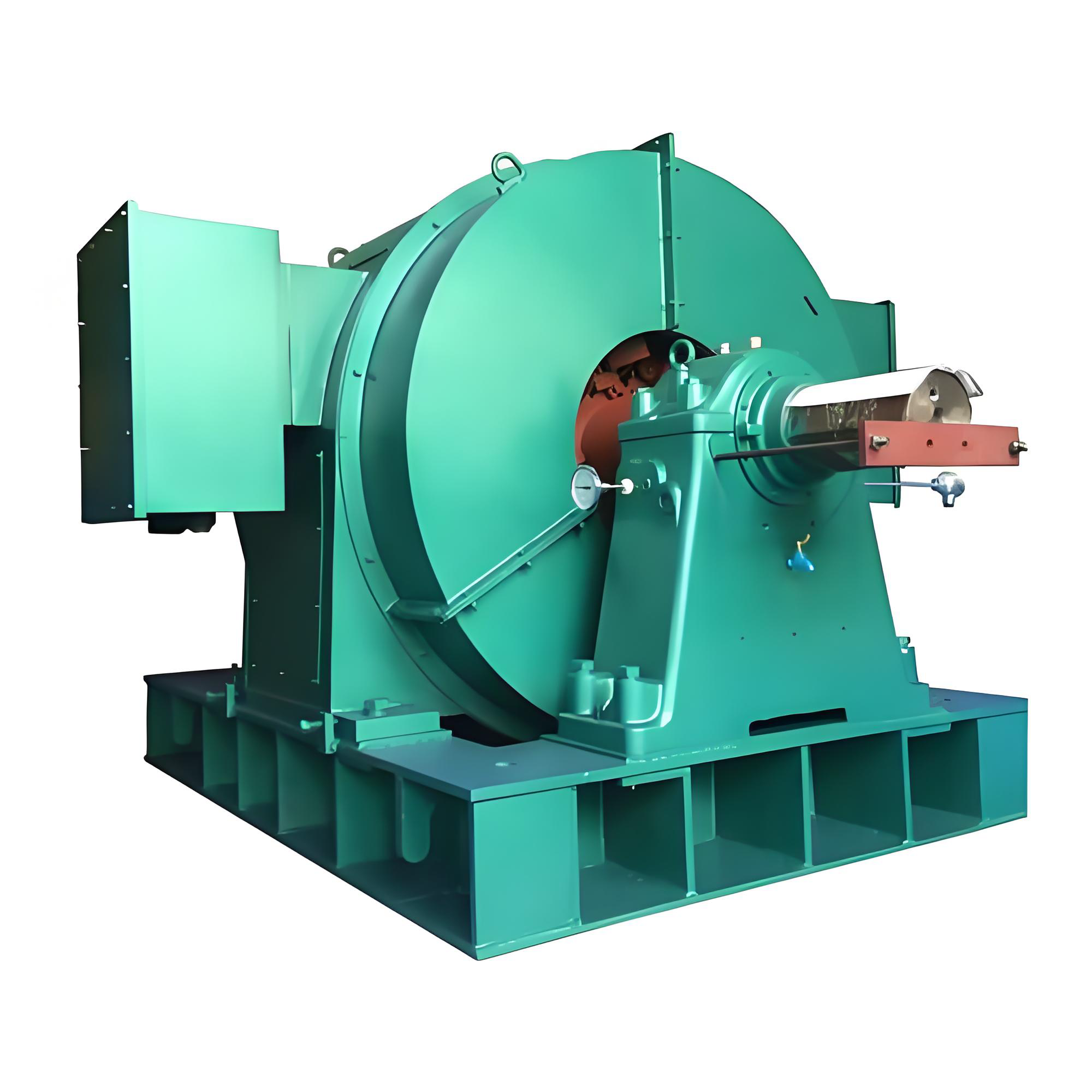

III. Projeto e configuração estrutural

1. Estrutura do motor principal

- Moldura: Altoqualidade welded steel frame with output end at base; designed for strength and rigidity.

- Estator: Laminated low-loss 0.5 mm silicon steel, with radial ventilation for effective cooling.

- Rotor: Premium steel poles with high-precision dynamic balancing; B-class or F-class insulated windings ensure smooth operation.

2. Rolamentos e lubrificação

- High-performance sleeve bearings with reliable lubrication and temperature control.

- Anti-shaft current design protects bearings from electrical erosion.

- Advanced lubrication system ensures consistent performance during long-term operation.

3. Ventilation and Cooling

- Open Natural Ventilation: For clean environments; simple structure, easy maintenance.

- Fully Enclosed Ducted Ventilation: For dusty or harsh environments, preventing contamination.

IV. Applications and Use Cases

1. Main Equipment

- Grid Ball Mills: For grinding metal and non-metal ores.

- Rod Mills: For raw material preparation in metallurgical and construction industries.

- Coal Mills: For pulverizing coal in thermal power plants.

2. Applicable Industries

- Mining: Ore crushing and grinding processes.

- Metallurgy: Material preparation and processing.

- Geração de energia: Key drive for coal mills.

- Building Materials: Cement and ceramics raw material grinding.

V. Product Advantages and Value

1. High Efficiency and Energy Saving

- High Power Factor: 0.9 leading, improves grid quality and reduces reactive power compensation costs.

- Optimized Efficiency Curve: Computer-optimized design ensures high efficiency near rated load.

- Low Loss Design: Low-loss silicon steel and optimized electromagnetic parameters minimize iron and copper losses.

2. Operational Reliability

- Strong starting torque ensures smooth startup of heavy mill equipment.

- High thermal margin with F-class or higher insulation.

- Moisture-resistant windings with vacuum pressure impregnation for excellent mechanical strength.

3. Conveniência de manutenção

- Easy-to-service structure for routine inspections.

- Modular components reduce spare parts inventory and replacement difficulty.

- Monitoring interfaces pre-installed for condition monitoring and predictive maintenance.

VI. Diretrizes de instalação e operação

- Environment: Indoor, altitude ≤1000 m, temperature ≤40°C, low dust, free of corrosive gases.

- Foundation: Solid and level to withstand motor weight and mechanical stress.

- Coupling: No radial or axial load on motor shaft; pneumatic clutch recommended for heavy-load starts.

- Electrical Connections: Correct wiring, excitation system, and protective devices (overcurrent, overload, undervoltage, differential).

VII. Serviço e suporte técnico

- Controle de qualidade: ISO9001, ISO14000, OHSAS18000 certified.

- Testing: Multiple insulation, no-load, load, and overspeed tests.

- After-Sales Support: 24-hour response, 48-hour on-site service.

- Lifetime Support: Continuous technical assistance and warranty coverage.

O SIMO TDMK36 36-pole extra-large synchronous motor provides reliable, high-efficiency, and robust power for mining mill drives. Choosing the TDMK36 ensures stable operation, high energy efficiency, and comprehensive technical support for demanding mining applications.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206