摘要:

The motor brush holder is a critical component that securely holds brushes in place to ensure efficient electrical contact with the commutator. It contributes to smooth motor operation, stable performance, and extended motor lifespan.

SIMO Motor Brush Holders: Exceptional Performance and Long-Lasting Stability

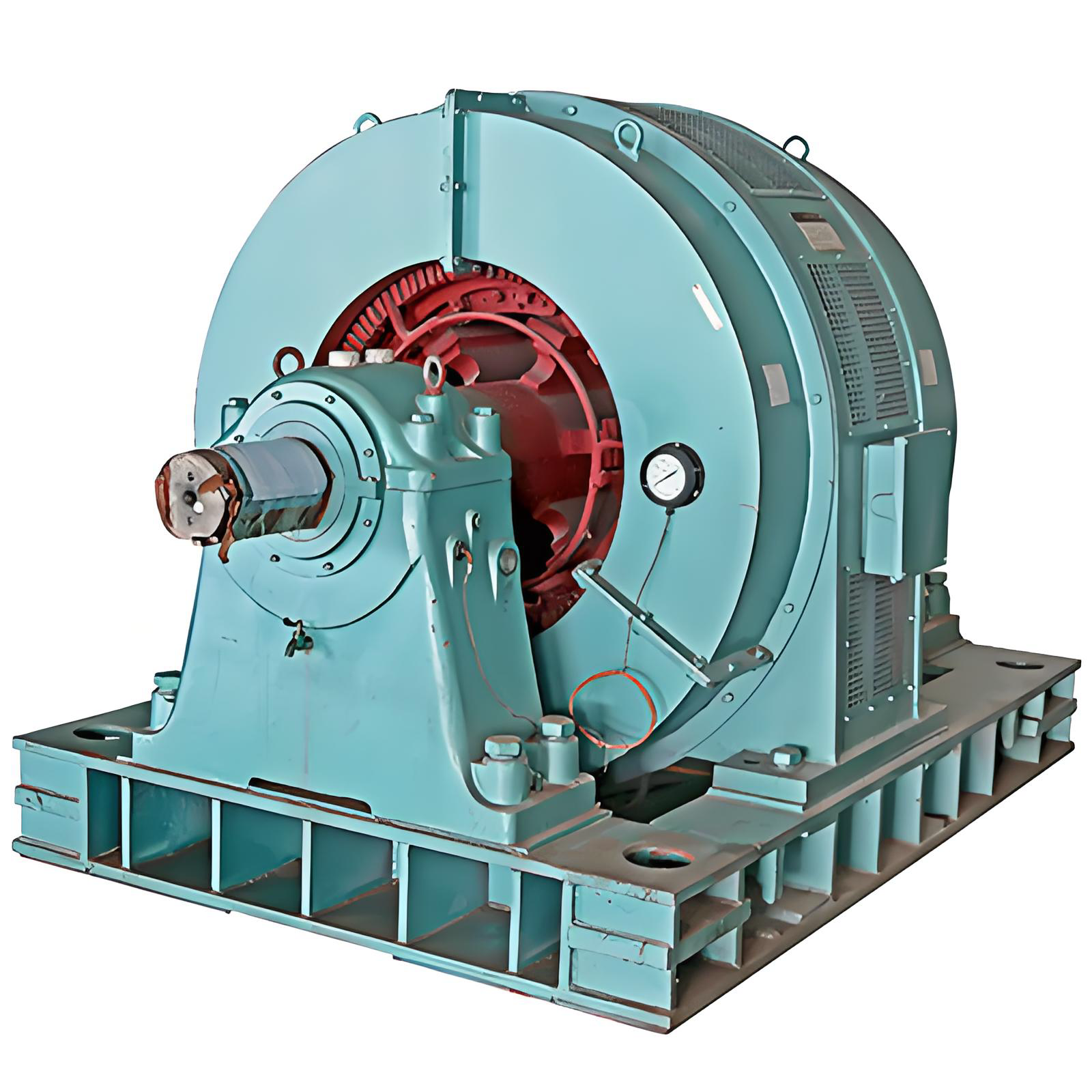

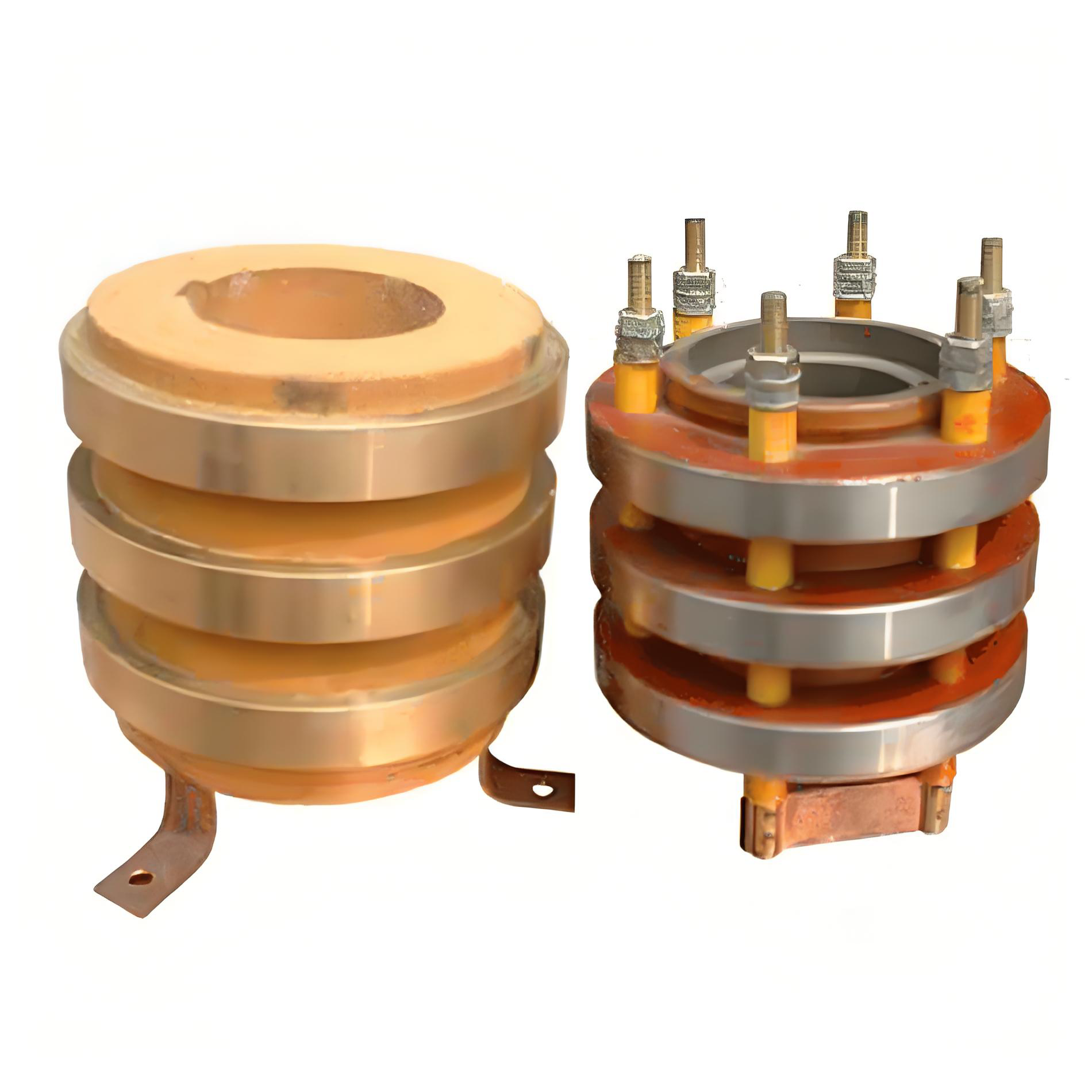

01 Product Overview: Key Component for Reliable Motor Operation

SIMO Motor brush holders (also known as brush grips) are critical components designed for AC and DC motors, ensuring stable electrical contact between brushes and commutators or slip rings. By applying consistent spring pressure, brush holders maintain reliable current transfer between stationary and rotating parts. The qualité of the brush holder directly affects motor efficiency, operational stability, and lifespan.

Manufactured with premium materials and precision engineering, SIMO brush holders feature robust structures, stable pressure, and easy installation. They are widely used in metallurgy, power generation, cranes, traction motors, and industrial machinery.

02 Core Technical Features

1. Optimized Structural Design

- Brush Slot Section: Secures carbon brushes in place with precision machining for accurate dimensions.

- Pressure Mechanism: Applies controlled pressure to prevent brush vibration during operation.

- Frame Section: Connects the brush slot and pressure mechanism to form a stable load-bearing system.

- Mounting Base: Firmly attaches the brush holder to the motor, ensuring overall stability.

Tolerance Standards: Brush slot bore radial tolerance H7, axial tolerance H11 for optimal commutator or slip ring contact.

2. Premium Material Selection

- High-Strength Materials: Bronze castings, aluminum, and advanced composites withstand mechanical stress.

- Excellent Machinability: Ensures precise and consistent part fabrication.

- Corrosion Resistance: Suitable for harsh industrial environments.

- Efficient Heat Dissipation: Reduces operating temperature for longer life.

- Stable Conductivity: Ensures reliable current transfer.

3. Precision Manufacturing Process

- Multi-Bore Processing: Ensures coaxiality with multi-tool machining, maintaining tolerances ≤0.36mm.

- Surface Treatment: Ni, Zn, Cr, copper plating, chemical oxidation, or acid pickling to suit operational environments.

- Quality Control: Eliminates burrs or sharp edges that may cause electrical discharge in humid conditions.

03 Performance Advantages

1. Stable and Reliable Operation

- Ensures brushes maintain consistent contact for smooth motor performance under various conditions.

- Simplifies maintenance with easy brush insertion and removal.

- Adjustable brush protrusion prevents damage to commutators or slip rings.

2. Optimized Pressure Control System

- Metallurgy, Power, Crane Motors: 0.15–0.35 Kg/mm²

- Traction Motors: 0.3–0.4 Kg/mm²

- Pressure consistency across all brush holders ≤10%, ensuring even current distribution.

3. Long Service Life

- Precision springs and pivot mechanisms ensure smooth operation without sticking.

- Robust riveted joints prevent component detachment.

04 Application Fields

1. Industrie lourde

- Metallurgy: Rolling mills, smelting equipment.

- Production d'électricité: Generator sets, auxiliary motors.

- Cranes: Bridge cranes, gantry cranes, lifting mechanisms.

2. Transportation

- Traction Motors: Electric locomotives, urban rail transit.

- Electric Vehicles: Motors for various electric transport vehicles.

3. Industrial Manufacturing

- Machine Tools: Industrial processing machinery.

- Pompes: Industrial water pumps, hydraulic systems.

- Compressors: Air compressors, refrigeration compressors.

05 Technical Specifications

| Catégorie de paramètres | Technical Specifications |

|---|---|

| Brush Slot Bore Tolerance | Radial H7, Axial H11 |

| Surface Roughness | Ra3.2–Ra1.6 (special requirements up to Ra0.8) |

| Coaxiality | Multi-bore tolerance ≤0.36mm |

| Parallelism | Brush holder fixed face to slot centerline ±0.2mm |

| Perpendicularity | Slot bottom face perpendicularity ≤0.25mm |

| Pressure Range | Standard motors: 0.15–0.35 Kg/mm²; Traction motors: 0.3–0.4 Kg/mm² |

06 Installation & Maintenance

Installation Guidelines

- Ensure brush holder fixed face is parallel to slot centerline within ±0.2mm.

- Maintain slot bore bottom perpendicular to sidewalls and fixed face ≤0.25mm.

Maintenance Tips

- Regular Inspection: Monitor pressure consistency.

- Brush Wear Monitoring: Replace brushes as needed.

- Pressure Adjustment: Adjust spring tension to prevent sparking caused by spring fatigue.

07 Fault Diagnosis & Solutions

- Sparking: Check and adjust spring pressure.

- Uneven Brush Wear: Ensure brush holder pressure uniformity ≤10%.

- Abnormal Vibration: Inspect brush holder fixation and component integrity.

08 Service & Support

- Technical Consultation: Professional selection guidance and technical advice.

- Installation Support: Detailed installation manuals and on-site guidance.

- After-Sales Guarantee: Full quality assurance and service support.

- Technical Assistance: Help troubleshoot operational issues.

SIMO Motor brush holders combine precision craftsmanship, stable performance, and long service life, making them the ideal choice for various industrial motors. Choosing SIMO brush holders ensures moteur fiable operation, reduced maintenance costs, and enhanced equipment performance, backed by advanced technology and rigorous quality control.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206