摘要:

The SIMO Z4 series DC motor is engineered for industrial applications requiring efficient and durable DC power. Known for its high performance and exceptional reliability, this motor is ideal for use in applications such as conveyors, electric drives, and automation systems.

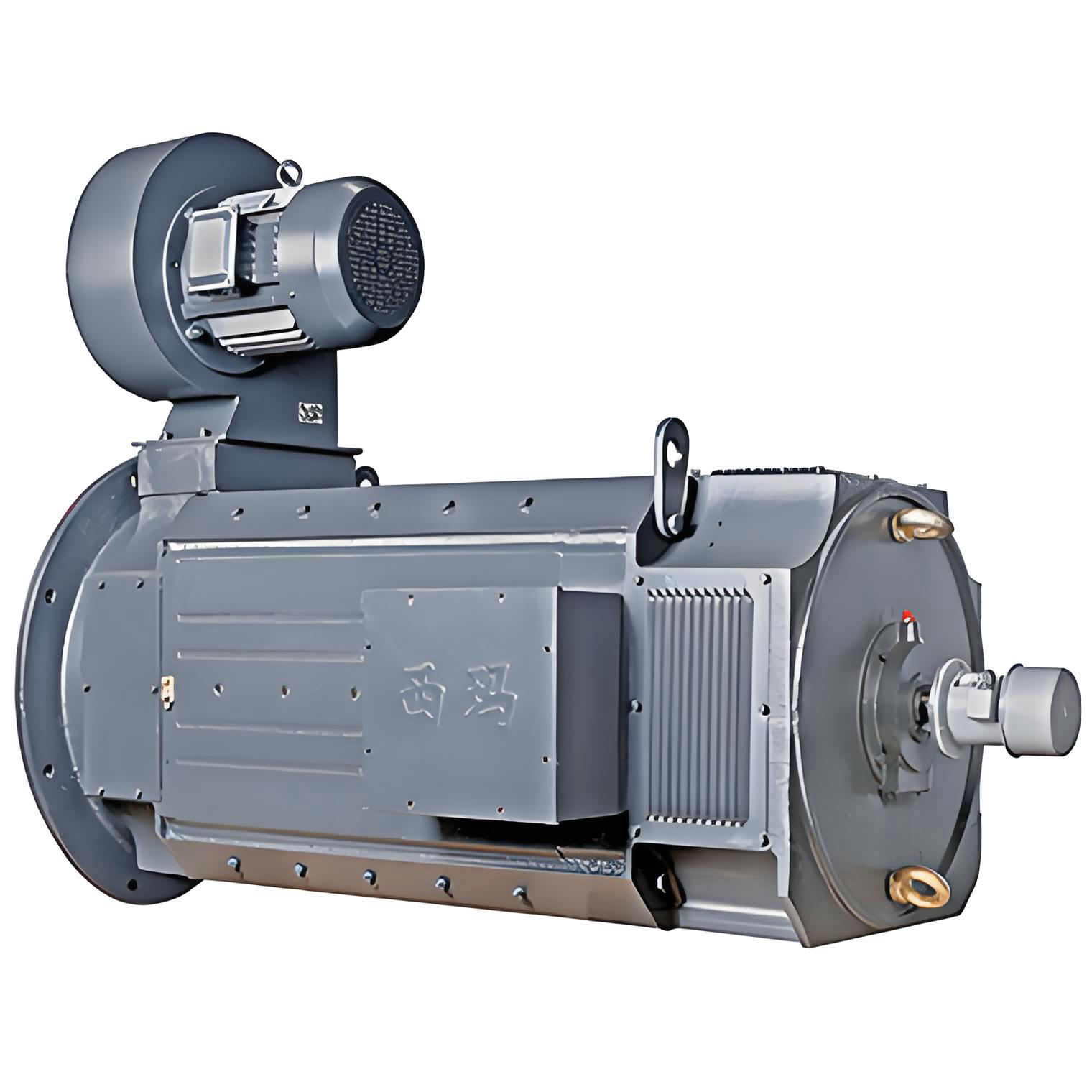

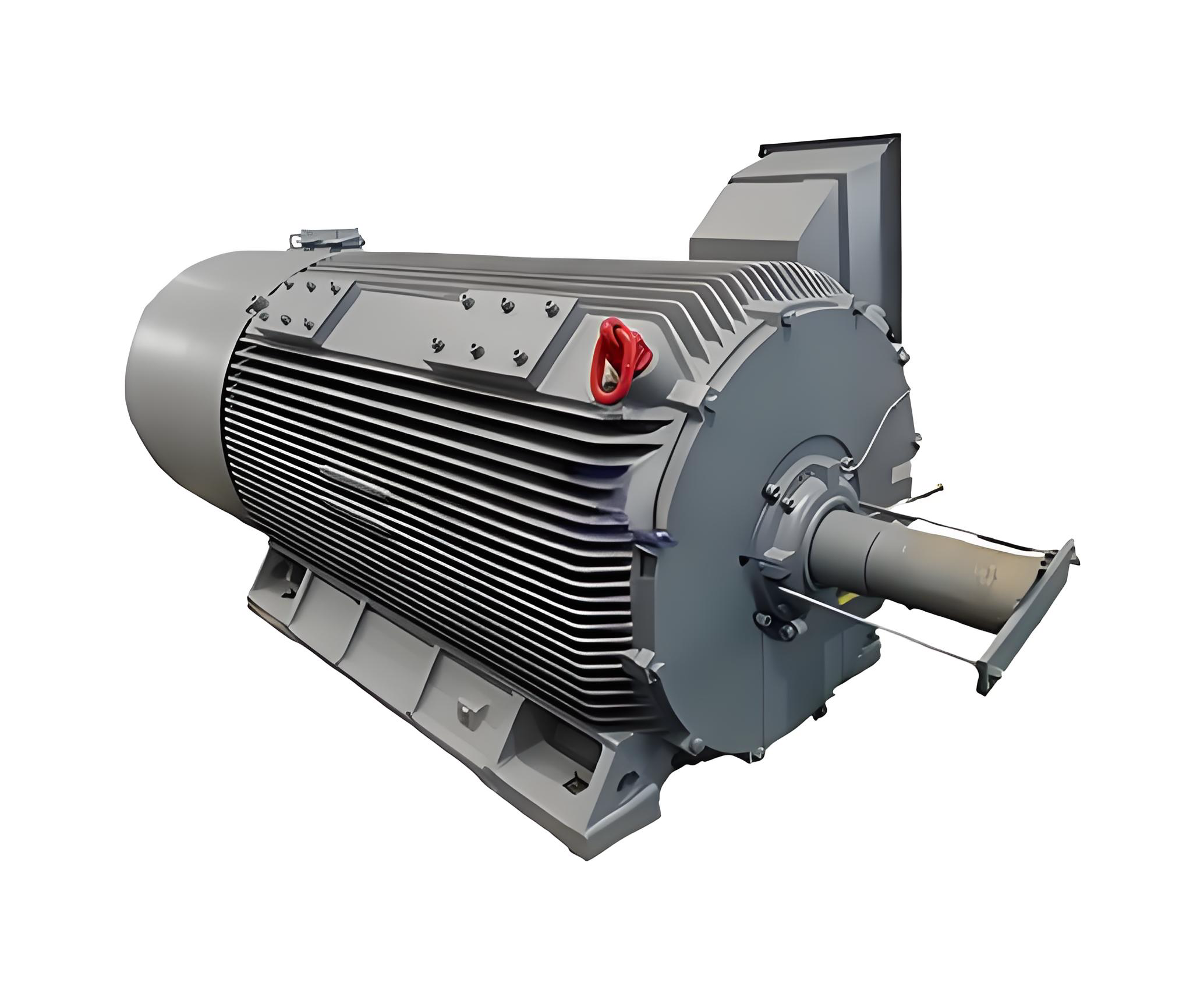

Xi’an Taifu Simo Motor Z4 Series Motor CC – High-Efficiency Industrial Drive Solution

Advanced International Technology for Precise and Reliable DC Power in Modern Industry

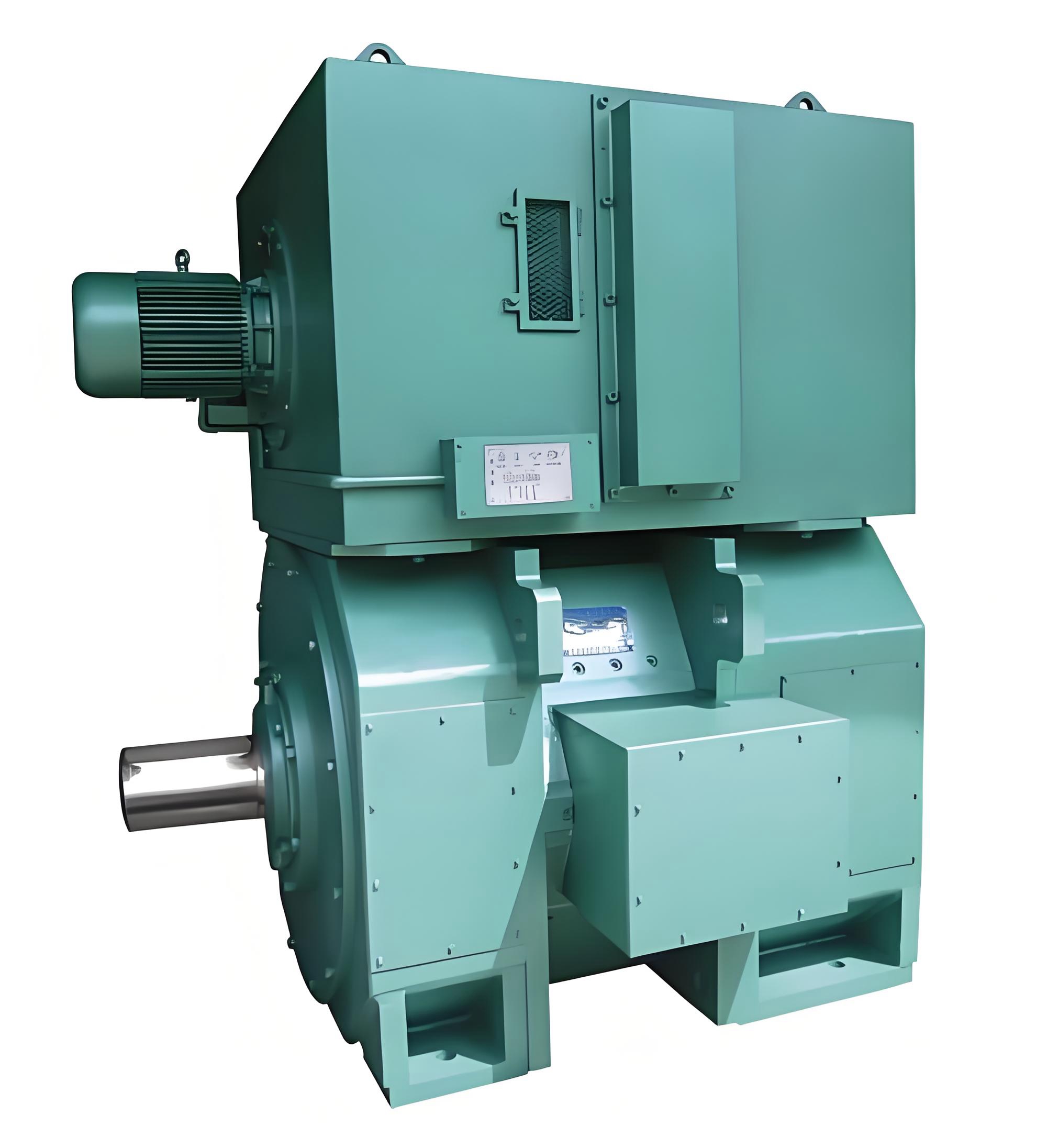

O Xi’an Taifu Simo Motor Z4 Series DC Motor represents the fourth-generation DC motor technology, integrating advanced electromagnetic design and innovative cooling systems. This series not only preserves the classic advantages of DC motors but also delivers major breakthroughs in dynamic response, speed regulation precision, and energy efficiency, making it an ideal choice for modern industrial automation and drive applications.

Model Identification – Accurate Recognition of Motor Specifications

O Z4 series DC motor uses a systematic model designation. For example, Z4-280-11B:

- “Z”: DC motor

- “4”: Fourth-generation series

- “280”: Center height 280 mm

- First “1”: Core length code

- Second “1”: Front end-cover size (1 = short, 2 = long)

- “B”: Compensation winding configuration

Special models such as Z4-112/2-1:

- First digit after “/”: motor pole count

- Second digit: core length code

The naming system follows IEC international standards e GB/T 4831 “Motor Model Coding Method”, ensuring clear identification and specification standardization.

Technical Overview – Innovative Design Leading the Industry

Standards and Specification Range

- Center height 100–355 mm: Small DC motors (JB/T6316-92 standard)

- Center height 400–450 mm: Standard series extended models

- Center height 500–710 mm: New-generation medium DC motors

Key Technical Features

Compared to previous Z2 and Z3 series:

- Power compatibility: Optimized for DC unit and static rectifier supply

- Dynamic performance: Lower rotational inertia, stronger load variation tolerance

- Control precision: Smooth speed regulation, automatic speed stabilization, fast response

Core specifications:

| Parameter | Specification |

|---|---|

| Power range | 1.5–840 kW |

| Rated speed | 9 standard options (3000–200 r/min) |

| Excitation | Standard separately excited, 180 V |

| Insulation | Class F |

| Environment | Altitude ≤1000 m, ambient ≤40℃ |

Advanced Structural Design – Solid Foundation for Performance

Innovative Electromagnetic Structure

- Octagonal laminated stator:

- +15% space utilization

- Enhanced pulsed current endurance

- Supports rapid load variation response

- Flexible winding configuration:

- Base models without series winding, supporting forward/reverse control

- Center height 315–450 mm: standard compensation winding

- Optional series winding customization

Diverse Cooling Systems

| Cooling Type | Suitable Environment | Advantage |

|---|---|---|

| IC06 | Standard industrial | Self-ventilation with fan |

| IC17 | Limited airflow | Ducted intake, louvered exhaust |

| IC37 | Enclosed space | Dual duct ventilation |

| IC611 | High dust | Fully enclosed air-to-air |

| ICW37A86 | High temperature | Fully enclosed air-to-water |

Installation and Protection

- Protection class: Base IP21S, supports higher levels

- Installation: Complies with GB/T997 and IEC standards

- Terminal box: Standard forward, optional reverse

- Shaft extension: Standard left-side, dual extension optional

Core Advantages – Redefining DC Motor Performance

Superior Speed Regulation

- Wide regulation range for versatile applications

- High speed stability via automatic stabilization

- Fast dynamic response to load and speed commands

High-Efficiency Energy Conversion

- Optimized electromagnetic design reduces iron and copper losses

- Improved commutation extends brush life

- Enhanced heat dissipation ensures sustained power output

Broad Application Adaptability

- Metallurgy: Rolling mill drives

- Machine tools: Precision metal cutting equipment

- Process industry: Paper, textile, printing machinery

- Heavy industry: Cement, plastic extrusion equipment

Intelligent Control Integration

Supports additional modules:

- Tachogenerators for precise speed feedback

- Pulse generators for position control

- Centrifugal switches for speed monitoring

- Brake systems for rapid stop

Power adaptability:

- 160V models: recommended with external reactor

- 440V models: direct operation

- Special voltage and excitation options available on request

Xi’an Simo Motor Quality Assurance System

Certifications and Standards

- National standard: GB/T755 Basic Requirements for Rotating Machines

- International standard: VDE0530

- Quality system: ISO9001

- Safety certifications: CE, UL, CCC

Technical Service Commitment

- Full qualidade control with non-conforming units rejected

- 72-hour continuous operation test for performance verification

- On-time delivery guarantee, special arrangements as needed

- 24-hour technical response, 48-hour onsite service

- Three-guarantee policy and lifetime cost-based warranty

Professional Selection and Ordering Guide

Standard Selection Parameters

| Factor | Standard Option | Custom Option |

|---|---|---|

| Power range | 1.5–840 kW | Custom power |

| Voltage | 160 V / 440 V | Special voltage |

| Speed levels | 9 standard | Custom speed |

| Cooling | 5 standard types | Custom cooling |

| Installation | IMB3 | Special mounting |

Ordering Requirements

- Complete motor model and specifications

- Rated power and voltage

- Speed range and excitation parameters

- Installation and structural requirements

Special configurations:

- Environment: tropical “TH” for humid conditions

- Structural changes: reverse box, reverse rotation

- Accessories: brushes, brush holders, spare parts

- Non-standard: technical agreements for custom parameters

Application Recommendations

- Metallurgical rolling mills: high dynamic response, precise speed control

- Precision machine tools: smooth low-speed operation, high torque output

- Production line drives: multi-motor synchronization and coordinated control

- Special equipment: reliable operation in challenging environments

Selection considerations:

- Load characteristics: constant torque/power requirements

- Speed regulation: accuracy requirements

- Duty cycle: continuous or intermittent operation

- Environmental conditions: temperature, humidity, dust levels

Conclusão

O Xi’an Taifu Simo Motor Z4 Series DC Motor combines cutting-edge design, exceptional performance, and reliable operation, establishing itself as a critical solution for modern industrial drives. Leveraging strong technical expertise and a comprehensive service system, Motor Juca provides professional technical support and dependable after-sales service.

For detailed technical specifications or personalized selection advice, contact the Simo Motor expert technical team for full-service support.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206