摘要:

The G series variable frequency fan is designed for industrial ventilation applications requiring adjustable speed and energy efficiency. With variable frequency drive (VFD) technology, it provides precise airflow control, reduces energy consumption, and ensures reliable performance in diverse industrial environments.

SIMO Motor G-Series Variable Frequency Fans: Efficient and Intelligent Ventilation Solutions

In modern industrial applications, G-Series Variable Frequency (VFD) Fans are emerging as core components for industrial ventilation and cooling, thanks to their exceptional energy efficiency and precise airflow control.

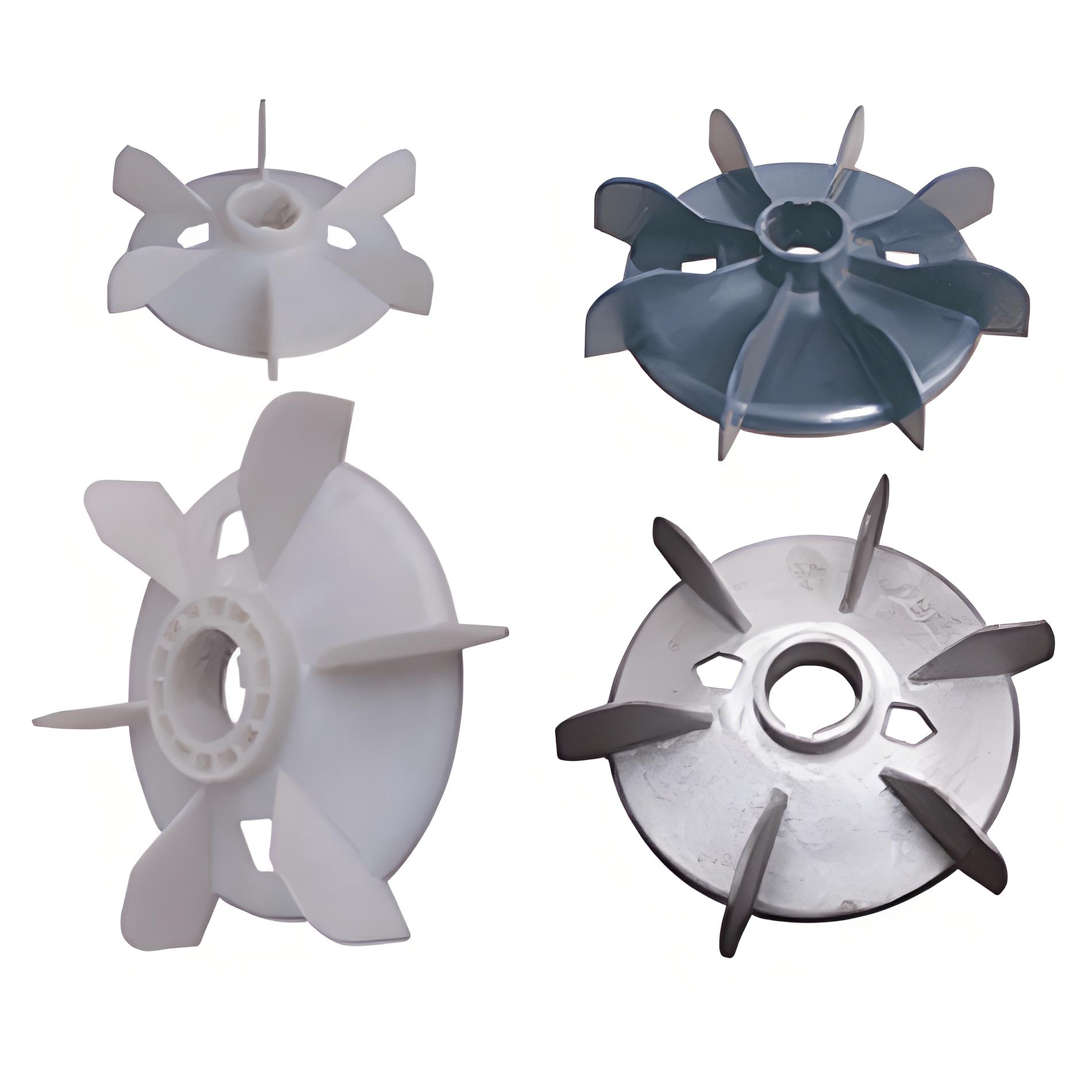

Designed specifically for variable frequency motors, G-Series fans comply with GB/T 22712-2021 standards for VFD motor cooling fans. They feature advanced aerodynamic design and high-qualidade materials, primarily used for cooling YVF2 series VFD-specific three-phase asynchronous motors, offering high efficiency, low noise, compact structure, and easy installation.

Overview and Core Functionality

G-Series VFD fans are critical for maintaining optimal motor operating temperature through intelligent airflow control. By ensuring effective heat dissipation under varying conditions, these fans extend motor lifespan, reduce system energy consumption, and support industrial energy-saving goals.

Key Technical Features

1. High-Efficiency Energy Saving

- Optimized Blade Design: Precisely calculated blade angles and curved surfaces deliver smooth, concentrated airflow, maximizing output efficiency. For instance, the G180 model delivers 1300 m³/h airflow at only 80W power consumption.

- Efficient Motor Integration: Equipped with dedicated VFD motors, maintaining high efficiency across variable speeds, avoiding energy loss common in traditional fans.

- Intelligent Speed Control: Automatically adjusts rotation based on cooling demand, preventing over-ventilation and reducing operational energy costs.

2. Low Noise Operation

- Aerodynamic Noise Optimization: Special impeller design and airflow channels minimize turbulence and vortices.

- Vibration Control Technology: High-precision dynamic balancing ensures smooth operation and reduces structural noise.

- Sound-Absorbing Materials: Key areas incorporate acoustic materials, keeping operation below 60dB for models like G180, outperforming similar products.

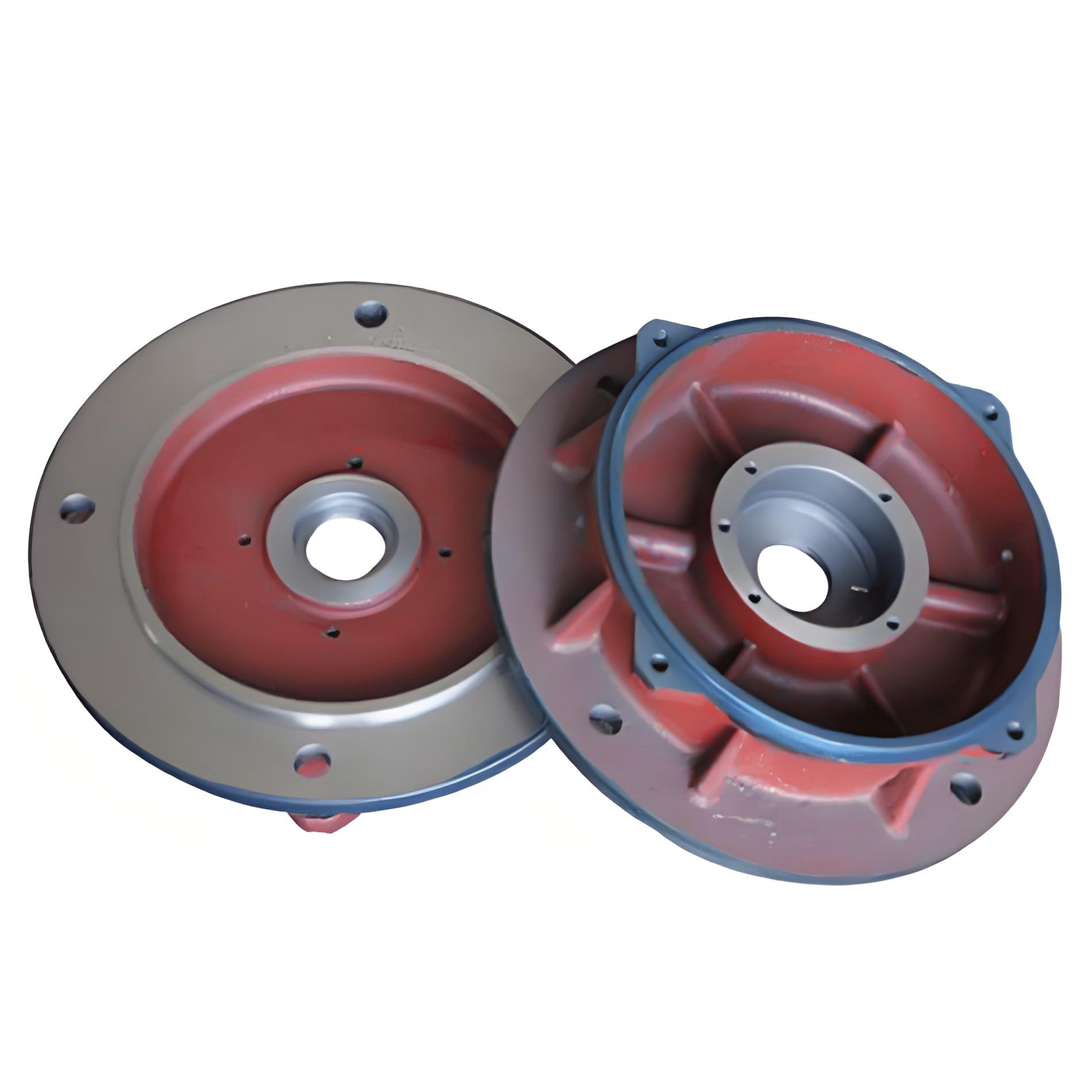

3. Robust and Durable Structure

- Premium Materials: High-strength iron casing ensures structural integrity and effective heat dissipation.

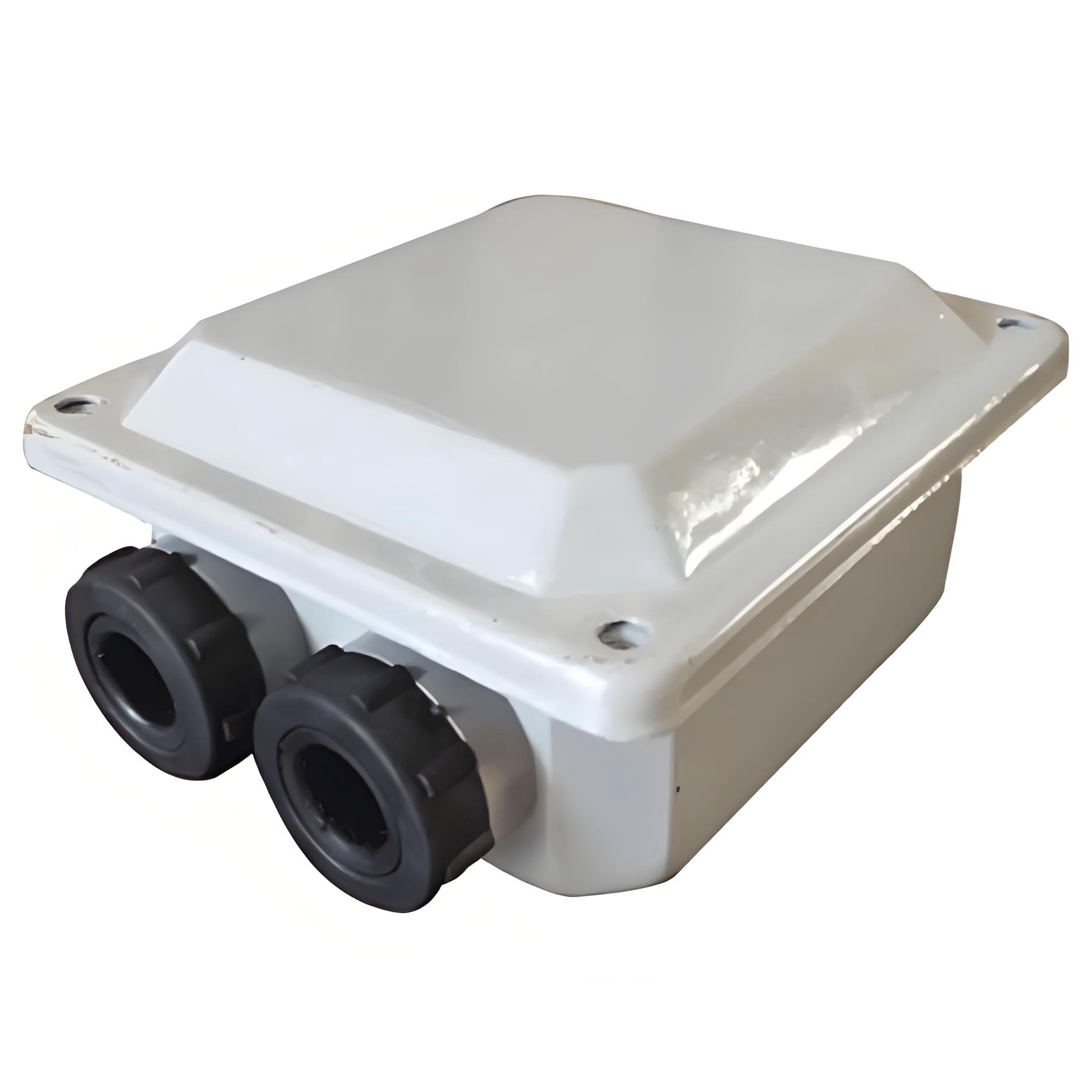

- High Protection Level: Standard IP55, preventing dust and water ingress in harsh environments.

- Temperature Resistance: Stable operation in environments up to 40℃, suitable for high-temperature industrial applications.

Technical Specifications

| Parameter | Specification | Notes |

|---|---|---|

| Model Example | G180A | Standard type |

| Potência nominal | 80W | - |

| Rated Speed | 1350 r/min | - |

| Maximum Airflow | 1300 m³/h | - |

| Air Pressure | 55 Pa | - |

| Noise Level | ≤60 dB | - |

| Protection Level | IP55 | Customizable |

| Classe de isolamento | F | - |

| Voltage | 380V/50Hz | Customizable |

Custom Options:

- Mounting Options: Horizontal, vertical, or rain-shielded installation.

- Cable Outlet: Right, left, or top exit configurations for easy wiring.

- Additional Features: Optional brakes, encoders, and accessories for advanced control.

Applications

1. Industrial Manufacturing

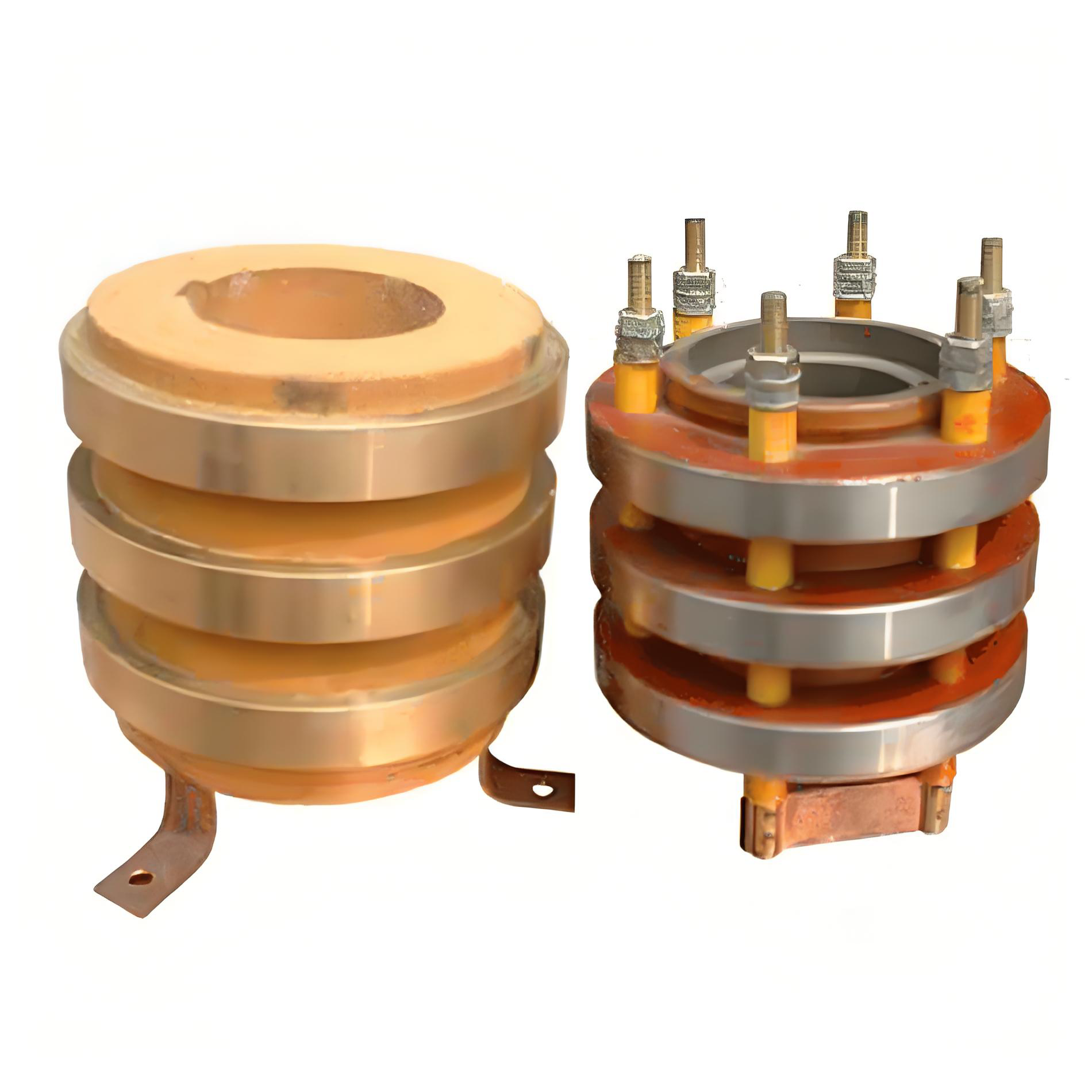

- VFD Motors: Cooling for YVF2 series three-phase asynchronous motors.

- Heavy Machinery: Mining and metallurgical motors requiring stable operation under heavy load.

- Production Lines: Cooling for machine tools, conveyors, and automated equipment, ensuring uninterrupted production.

2. Infrastructure

- HVAC Systems: Chillers, air handling units, and fan coil units with demand-based airflow.

- Water Treatment: Cooling for pumps and ventilation fans in continuous operation.

- Power Facilities: Forced cooling for generators and substation equipment.

3. Special Environments

- Dusty Conditions: High protection rating ensures reliable operation in cement, construction, and powder-laden environments.

- High Temperatures: Maintains performance in hot workshops or heat-treatment facilities.

- Alta umidade: Sealed design suitable for underground projects and offshore platforms.

Advantages and Benefits

1. Eficiência energética

- Demand-Based Airflow: Adjusts based on motor temperature to prevent energy waste.

- High Efficiency Across Speed Range: Saves 20%-40% energy compared to fixed-speed fans.

- Reduced Operating Costs: Lower energy consumption shortens payback period.

2. Equipment Protection

- Stable Motor Temperature: Extends insulation life and motor lifespan.

- Reduced Thermal Stress: Smooth temperature control prevents damage from sudden heat changes.

- Improved System Reliability: Reduces overheating risk, ensuring consistent production performance.

3. Installation and Maintenance

- Compact Design: Fits limited spaces easily.

- Standardized Interfaces: Direct compatibility with multiple VFD motor models.

- Easy Maintenance: Modular design simplifies inspection and servicing, reducing downtime.

Selection and Installation

1. Selection Considerations

- Motor Power Match: Select fan model based on motor power and heat load.

- Space Constraints: Ensure sufficient installation and airflow space.

- Environment: Consider temperature, humidity, and dust levels for protection rating selection.

- Control Requirements: Determine if intelligent temperature control is needed.

2. Installation Guidelines

- Stable Foundation: Ensure flat, secure installation to prevent vibration and noise.

- Clear Airflow Path: Maintain unobstructed inlet and outlet for proper ventilation.

- Electrical Connections: Correct wiring and grounding to prevent faults.

Maintenance and Troubleshooting

1. Routine Maintenance

- Cleaning: Remove dust from blades and ducts regularly to maintain cooling efficiency.

- Tightening: Check bolts and terminal connections for stability.

- Bearing Maintenance: Lubricate or replace grease according to usage schedule.

2. Common Issues

- Reduced Airflow: Inspect and clean blades; check voltage supply.

- Vibration: Tighten fasteners or replace unbalanced impellers.

- Motor Not Running: Check power supply and control signals for electrical faults.

Service and Support

SIMO Motor offers full technical support for G-Series VFD fans:

- Expert Consultation: Guidance on selection and application.

- Custom Solutions: Tailored designs for unique requirements.

- After-Sales Guarantee: Quality assurance and support.

- Rapid Response: Efficient supply chain and service network for timely delivery and problem resolution.

SIMO Motor G-Series Variable Frequency Fans deliver advanced technology, reliable performance, and significant energy savings, making them the ideal solution for VFD motor cooling in modern industrial applications.

Choosing SIMO Motor G-Series Fans ensures efficient cooling, reliable operation, and energy savings, supporting industrial efficiency and sustainable growth.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206