摘要:

The DC motor commutator is a crucial component that ensures proper current direction in the motor windings, enabling smooth operation and efficient performance. Designed for durability and precision, it enhances the reliability and lifespan of DC motors.

SIMO Motor DC Commutators: Core Components with High Performance and Reliability

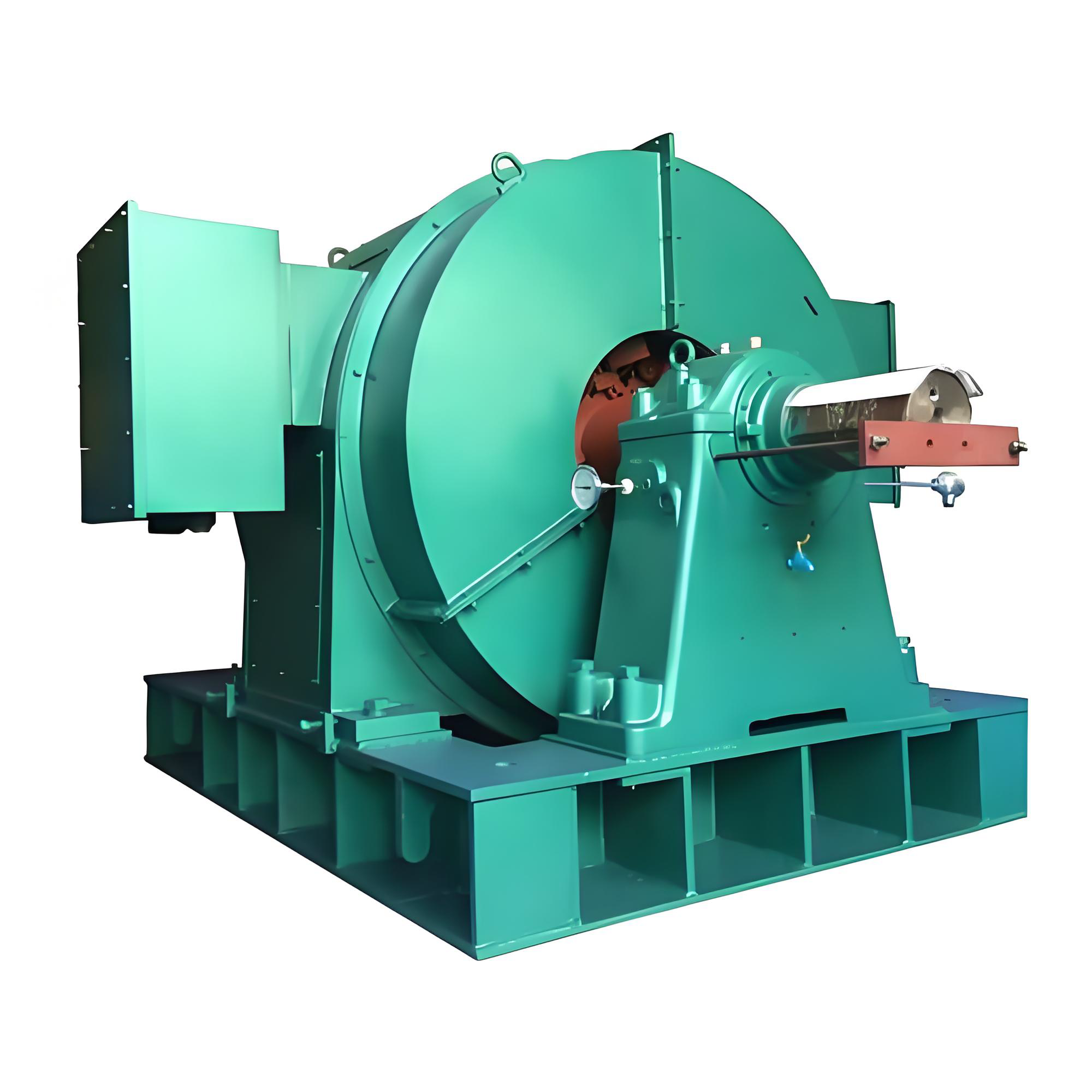

In modern industrial applications, DC motor commutators are critical execution components, and their performance directly affects the efficiency and reliability of the entire system.

01 Product Overview: The Heart of Motor CCs

DC motor commutators, also known as rotary rectifiers, are essential components in DC motors, DC generators, and AC commutator motors. SIMO Motor commutators are manufactured using high-qualidade copper and advanced insulating materials, employing precision machining to ensure stable current commutation at high rotational speeds.

Acting as the "heart" of a DC motor, the commutator enables automatic switching of current direction in the armature windings through sliding contact with brushes. In generator mode, it converts AC in the armature windings to DC across the brushes; in motor mode, it converts external DC into AC within the armature. Efficiency and reliability in this process are crucial to overall motor performance.

02 Working Principle and Technical Features

1. Basic Working Principle

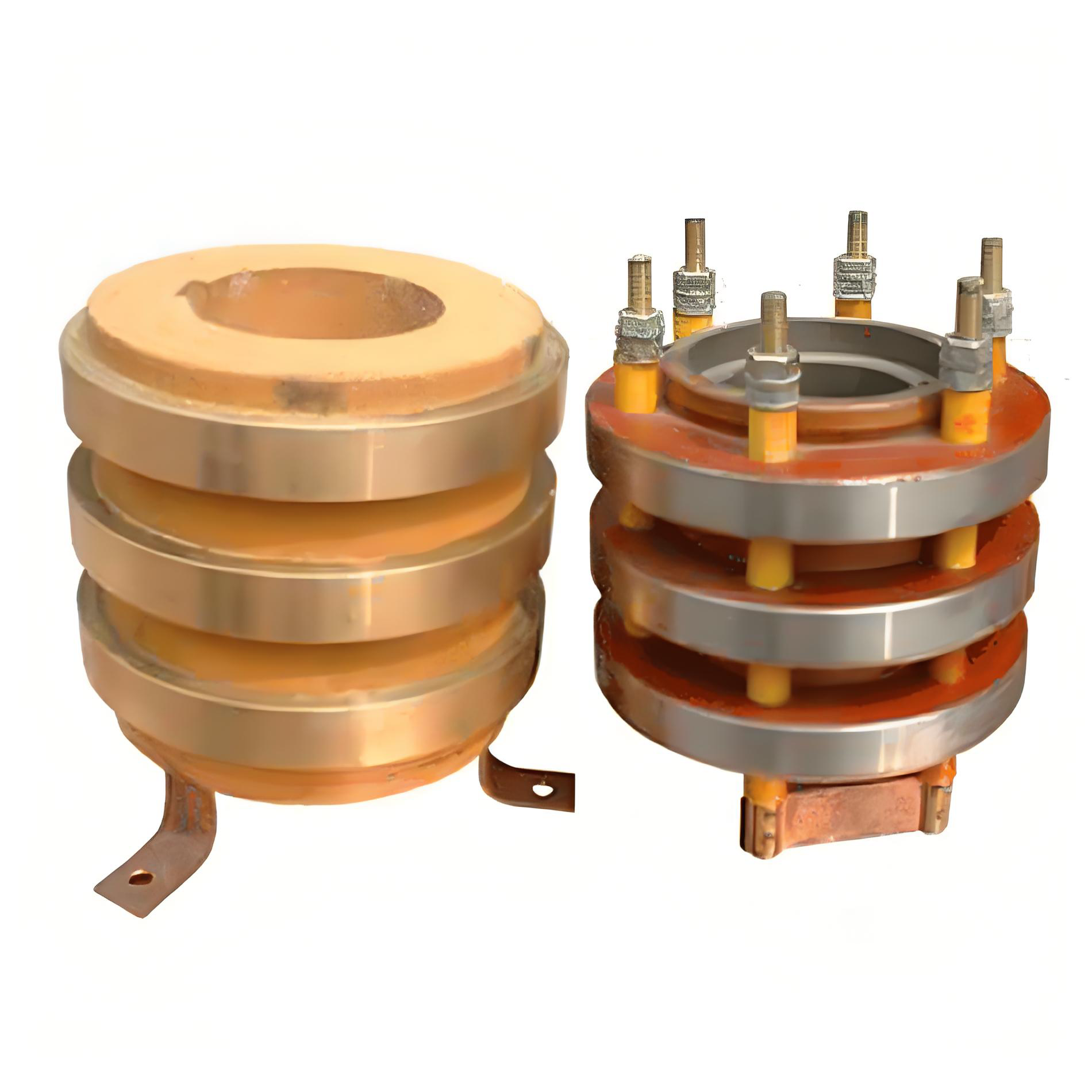

The commutator consists of multiple copper segments (commutator bars) arranged in a cylindrical or disc shape, insulated from each other with mica or other high-performance insulating materials. Each segment is connected to armature winding elements. As the armature rotates, the segments sequentially contact fixed carbon brushes.

- In DC generators, the commutator converts AC in the armature windings to DC at the brushes.

- In AC commutator motors, it ensures the brush-side AC frequency meets operational requirements.

2. Key Technical Features

- High-Quality Materials: Pure copper for excellent conductivity; high-temperature insulation ensures reliable separation.

- Precision Design: Uniform segment spacing and smooth surfaces reduce sparking and maintain stable brush contact.

- Dynamic Balancing: Ensures smooth operation at high speeds, reducing vibration and noise.

- Optimized Heat Dissipation: Structural design enhances thermal management to prevent performance degradation.

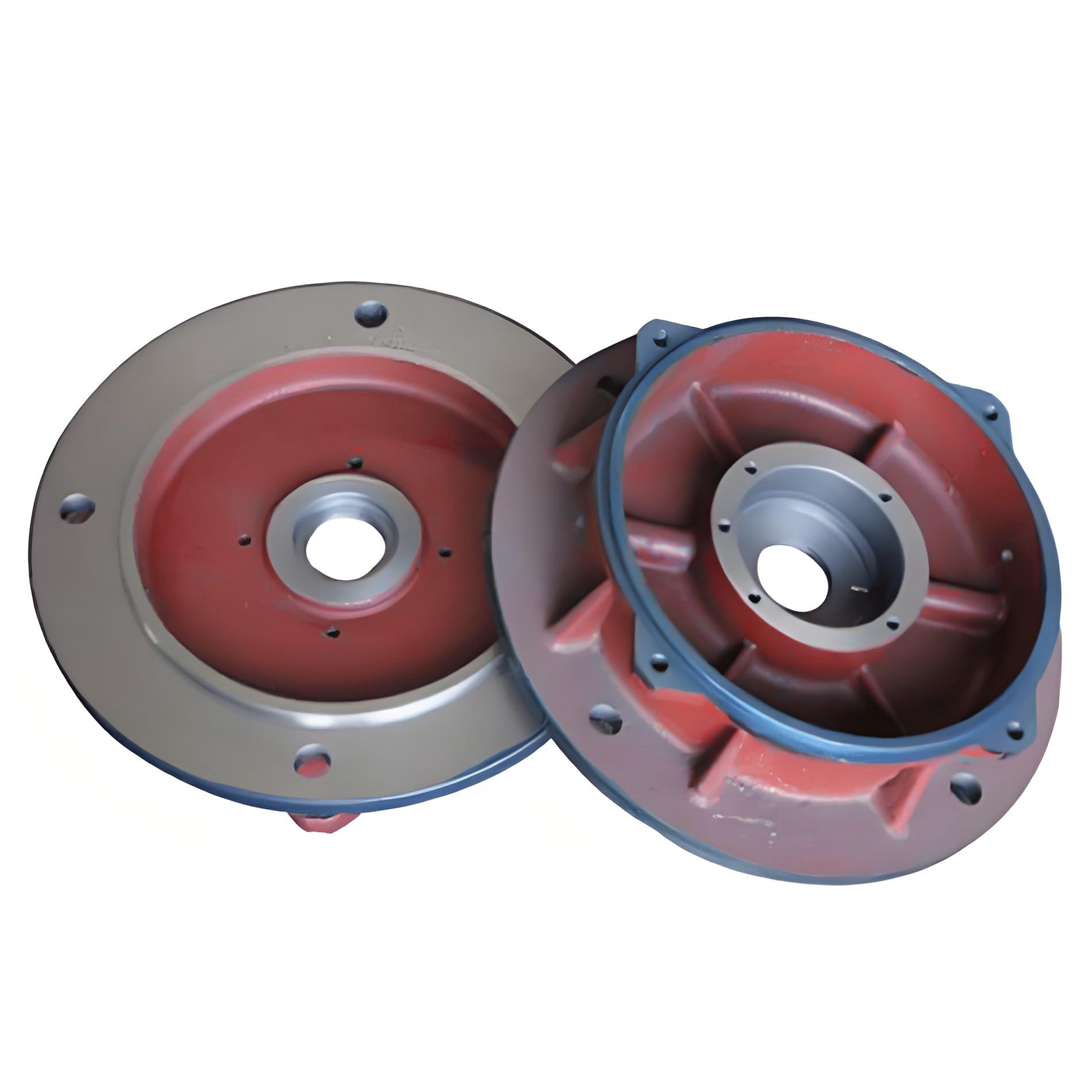

03 Core Structure and Technical Specifications

1. Component Structure

- Commutator Segments: Made of high-quality electrolytic copper, precision-turned and polished for optimal brush contact.

- Insulation Layers: Mica or advanced engineering plastics prevent short circuits; insulation ratings up to F/H class.

- Reinforcing Rings: For high-speed applications (>25,000 rpm), high-strength rings prevent deformation due to centrifugal force.

- Sleeves and Retaining Rings: Steel or alloy components that stabilize the segment assembly.

2. Key Technical Specifications

| Parameter | Specification | Application |

|---|---|---|

| Motor Speed | 25,000–55,000 rpm (high-speed types) | Power tools, household appliances |

| Segment Quantity | 9–123 | Industrial motors, large equipment |

| Diameter Range | Millimeter-level to 200 mm | Micro motors to large industrial motors |

| Classe de isolamento | B, F, H | General or high-temperature environments |

| Operating Temperature | -30℃ to 85℃ (motor environment) | Industrial general use |

| Maximum Rotor Temperature | 100℃ | Continuous operation |

04 Application Fields

DC commutators are vital across multiple industries:

1. Industrial Drives & Automation

- Heavy Machinery: Rolling mills, hoists, compressors, and high-power drives.

- Automation Equipment: Industrial robots, conveyor systems, packaging machinery.

- Production Lines: Textile machines, printing equipment, food processing lines.

2. Transportation

- Electric Vehicles: Drive motors and auxiliary actuators.

- Rail Transport: Traction motors for metro and high-speed rail.

- Aerospace: Aircraft starter generators, control actuators.

3. Household Appliances & Tools

- Home Appliances: Vacuum cleaners, mixers, washing machines.

- Power Tools: Drills, grinders, saws.

- Office Equipment: Printers, copiers, scanners.

05 Performance Advantages

- High-Efficiency and Stable Current Conversion

- Low contact resistance for minimal energy loss.

- Stable commutation reduces voltage fluctuations.

- Arc-resistant surface treatment extends service life.

- Long Service Life

- Wear-resistant copper segments maintain performance under prolonged brush friction.

- Anti-oxidation treatment prevents surface degradation.

- Robust structure resists centrifugal and thermal stress.

- Versatile Application

- Multiple sizes from micro to large industrial motors.

- Customizable materials, dimensions, and connections.

- Adaptable to harsh environments: dust, humidity, high temperature.

06 Selection and Installation Guide

1. Selection Considerations

- Electrical parameters: rated voltage, current, maximum speed.

- Mechanical dimensions: outer diameter, shaft hole, total length, segment count.

- Operating environment: temperature, humidity, vibration, cooling method.

- Expected service life: choose materials and manufacturing grade accordingly.

2. Installation Guidelines

- Clean surfaces to remove oils and dust.

- Ensure precise alignment and concentricity.

- Torque fasteners correctly to avoid stress or looseness.

- Match brushes with proper material and spring tension.

07 Maintenance and Troubleshooting

1. Regular Maintenance

- Inspect surface smoothness, check for wear, burns, or oxidation.

- Clean with anhydrous ethanol to remove carbon dust and oil residues.

- Measure insulation resistance between segments.

2. Common Issues and Solutions

- Excessive sparking: Check brush pressure, contact quality, or winding shorts.

- Surface burns: Minor burns can be precision-machined; severe cases require replacement.

- Insulation failure: Professional repair or replacement required.

- Uneven wear: Check brush material and spring pressure.

08 Service and Support

SIMO Motor provides comprehensive support:

- Technical consultation for product selection and applications.

- Custom design and manufacturing for special requirements.

- Quality assurance and after-sales service.

SIMO Motor DC Commutators are the core of DC motor performance, ensuring efficiency, reliability, and durability. With years of experience and precision manufacturing, SIMO Motor delivers high-quality commutators suitable for industrial, transportation, and household applications, supporting the development of industrial automation and intelligent systems worldwide.

Shaanxi Public Network Security No. 41032502000206

Shaanxi Public Network Security No. 41032502000206