摘要:

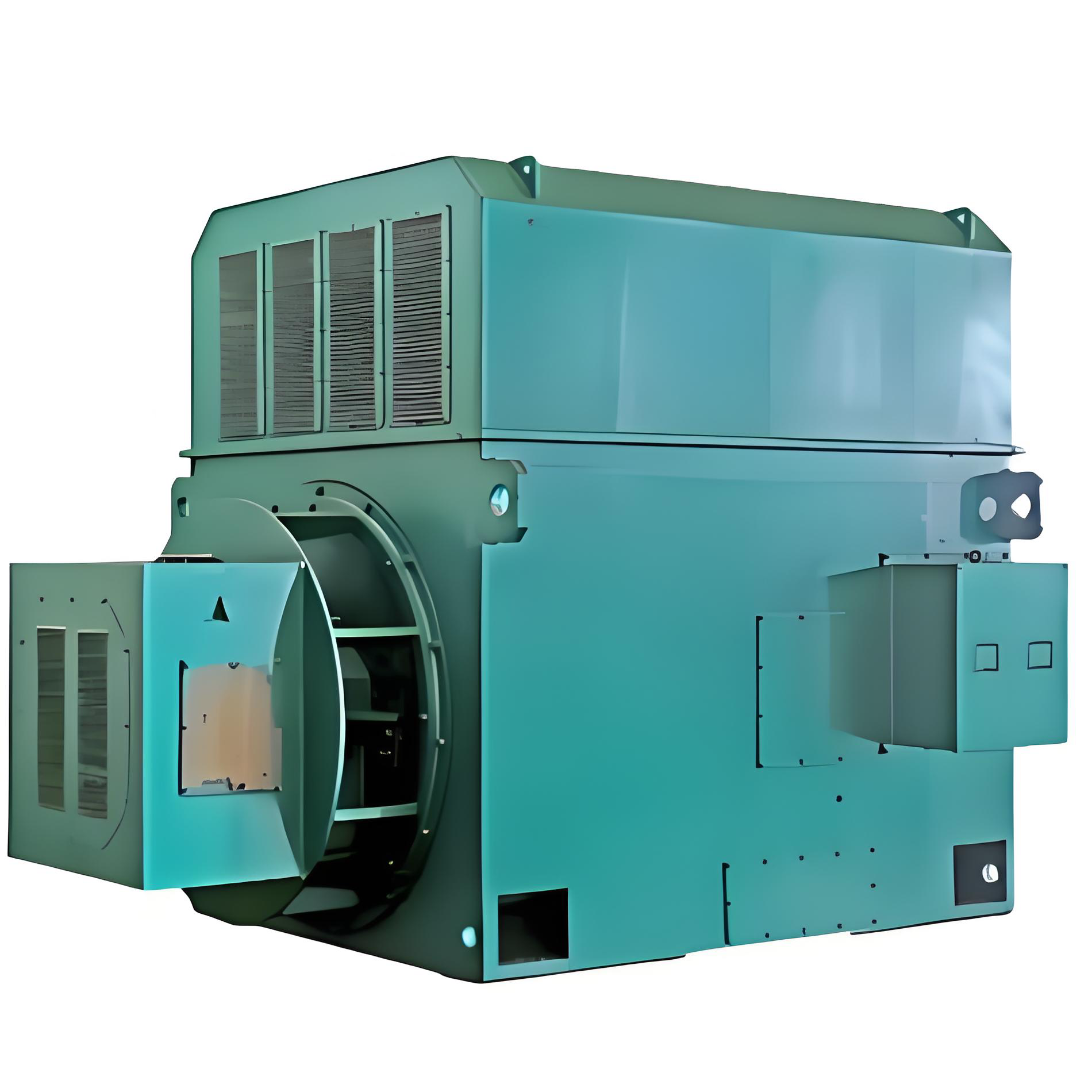

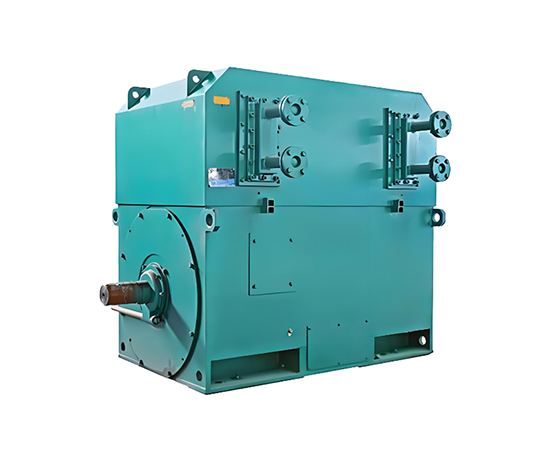

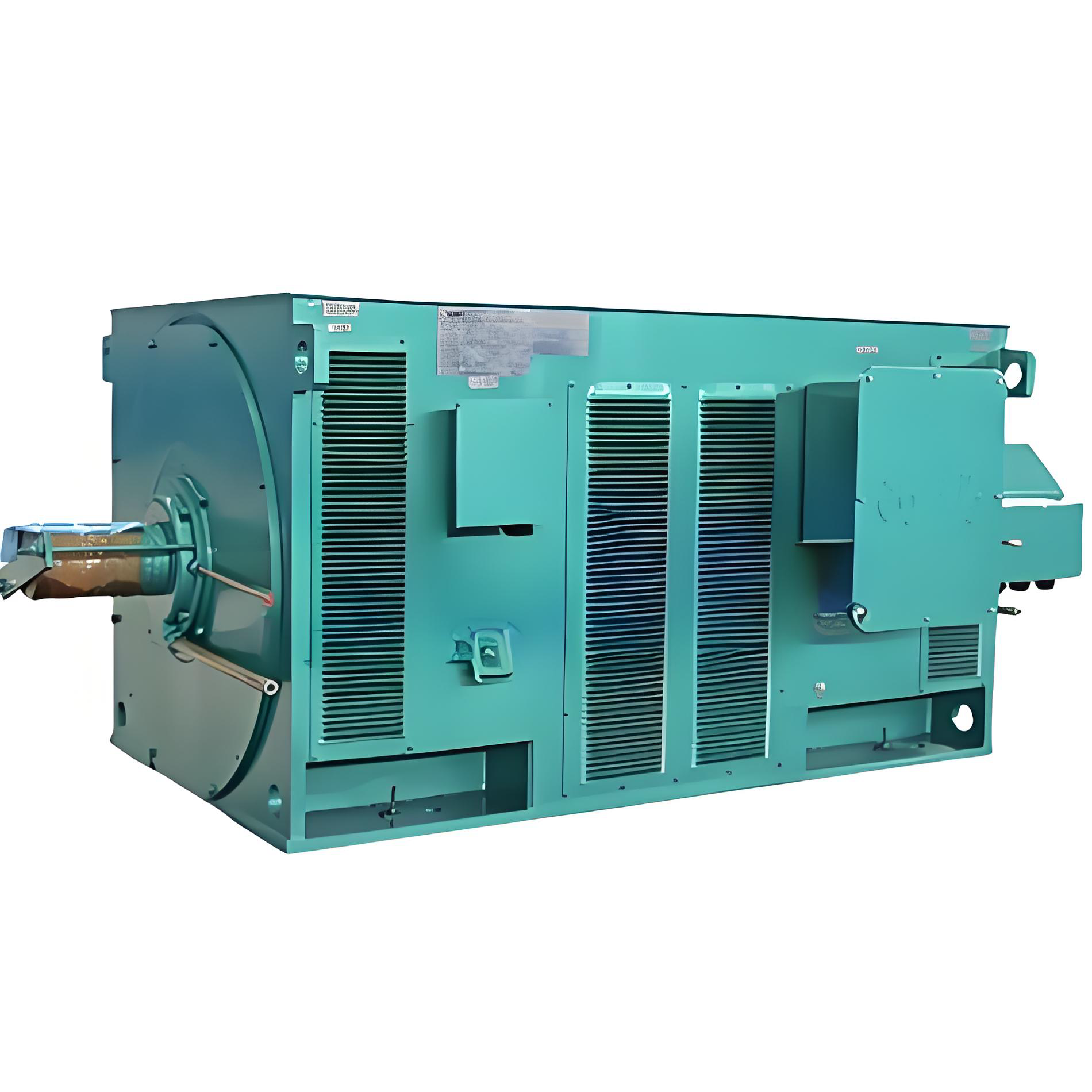

The YKK series high voltage three-phase asynchronous motor is designed for industrial applications that require reliable, high-performance power solutions. Offering high efficiency, durability, and excellent starting torque, it is ideal for power generation, mining, and large-scale machinery.

Xi’an Taifu Simo YKK Series High Voltage Three-Phase Motor asíncrono – Comprehensive Overview

Professional drive for industrial equipment, delivering reliable power solutions

En Xi’an Taifu Simo YKK Series (H355–1000) High Voltage Three-Phase Asynchronous Motor is a high-performance power product independently developed and manufactured by Xi’an Simo Motor (Group) Co., Ltd.

This series adopts a totally enclosed squirrel-cage rotor structure, featuring compact construction, stable performance, and wide applicability across multiple industrial sectors.

This document provides a detailed introduction to the model designation, product features, technical characteristics, performance parameters, and ordering instructions, helping users fully understand this premium high-voltage motor solution.

Model Designation – Understanding the Motor Code

The YKK series high-voltage motor model follows standardized coding rules.

Example: YKK3551-4

- YKK: Totally enclosed squirrel-cage induction motor with air-to-air cooler

- 3551: Frame center height 355 mm, No.1 core length

- 4: Number of poles

According to national motor designation standards, motor models consist of product code, specification code, special environment code, and supplementary code.

As a mainstream high-voltage motor series, the YKK range inherits proven design concepts while integrating multiple technical upgrades.

Product Overview – Professional Design with Multiple Advantages

Technical Standards and Structural Features

En YKK Series (H355–1000) 6 kV / 10 kV high-voltage three-phase asynchronous motors are totally enclosed squirrel-cage motors equipped with air-to-air coolers.

Protection class: IP44 or IP54

Cooling method: IC611 (in accordance with GB/T 1993)

Key advantages include:

- High efficiency and energy saving: Optimized electromagnetic design and airflow system reduce losses and improve operating efficiency

- Low noise and low vibration: Precision machining and dynamic balancing ensure smooth and quiet operation

- Compact structure: Reduced size and weight, saving installation space

- Easy maintenance: Rational design simplifies installation, inspection, and servicing

Wide Application Range

YKK series motors are ideal drive sources for various industrial equipment, including:

- Fans, compressors, and pumps

- Crushers and metal cutting machine tools

- Fixed equipment in coal mines, power plants, and industrial enterprises

With strong environmental adaptability, these motors operate reliably under complex and demanding working conditions.

Technical Features – Advanced Design and Reliable Performance

Box-Type Structural Design

The YKK series adopts a fully welded steel plate box-type frame and end covers with a detachable internal structure.

Protective covers and inspection panels are installed on the sides and top of the motor, allowing easy access to internal components for maintenance and repair.

This structure provides light weight, high rigidity, and excellent practicality.

High-Quality Insulation System

- Stator with slide-in external press-fit structure

- Stator windings use F-class low-resin insulation materials

- End windings are securely fixed and tied

- Treated with vacuum pressure impregnation (VPI) solvent-free varnish

This ensures excellent insulation performance, strong mechanical strength, and superior moisture resistance.

Motors rated above 6000 V are equipped with anti-corona protection measures.

Flexible Bearing Configuration

Bearings are available in rolling bearing or sleeve bearing designs, depending on motor power and speed.

Standard bearing protection class matches the motor enclosure (IP44 or IP54), with higher protection levels available when required.

Efficient Cooling System

A top-mounted enclosed air-to-air cooler provides excellent heat dissipation.

Cooling method IC611 ensures stable motor operation even in high-temperature environments.

Technical Parameters and Performance Characteristics

- Wide power range: 220 kW to 14,000 kW

- Rated voltage options: 6 kV, 10 kV (other voltages available on request)

- Power supply conditions:

- Rated frequency: 50 Hz

- Voltage tolerance: ±5%

- Frequency tolerance: ±1%

- Insulation class: F or H

- Mounting arrangements: IMB3, IMB35, and others

Xi’an Simo Motor Quality Assurance System

Xi’an Simo Motor (Group) Co., Ltd. is a professional manufacturer of medium and large AC/DC motors, integrating motor design, manufacturing, electrical control, machining, casting, logistics, automation, and turnkey power system solutions.

The company is certified to:

- ISO 9001 Quality Management System

- ISO 14001 Environmental Management System

- OHSAS 18000 Occupational Health and Safety Management System

- CE (Europe), UL (USA), and CCC (China) certifications

Quality Commitment

- Strict compliance with national standards and contractual technical requirements

- 72-hour full-load test after final assembly before delivery

- Guaranteed on-time delivery, with compensation mechanisms for delays

- Customer response within 24 hours; on-site service within 48 hours

- Repair personnel remain on site until faults are fully resolved

- Full warranty for calidad-related issues, including repair, replacement, or return

- Lifetime cost-based warranty after sale

Ordering Instructions

When placing an order, please specify the following technical details:

Basic parameters

- Motor model: YKK3551-4

- Rated power: 185 kW

Electrical parameters

- Rated voltage: 6000 V

- Rated frequency: 50 Hz

Performance parameters

- Rated speed: 1500 r/min

- Insulation class: F

Structural parameters

- Mounting type: IMB3

- Protection class: IP44 or IP54

Environmental conditions

- Ambient temperature: –15°C to +40°C

- Altitude: ≤ 1000 m

Important Notes

- Refer to the product catalog before ordering to confirm specifications

- Standard orders must clearly state model, power, voltage, frequency, noise level, and mounting type

- Special requirements such as double shaft extension, terminal box position reversal, reverse rotation, tropical design, or outdoor anti-corrosion design must be specified in advance

- From the drive end view, 2-pole motors rotate clockwise as standard; counterclockwise rotation must be specified at the time of order

Conclusión

En Xi’an Taifu Simo YKK Series (H355–1000) High Voltage Three-Phase Asynchronous Motor combines outstanding performance, reliable quality, and broad applicability, making it an ideal power solution for industrial applications.

With strict adherence to international quality standards and comprehensive after-sales support, Simo Motor ensures long-term, worry-free operation for customers worldwide.

For more information about YKK series high-voltage motors or customized power solutions, please contact the Simo Motor professional team.

Red pública de seguridad de Shaanxi nº 41032502000206

Red pública de seguridad de Shaanxi nº 41032502000206