摘要:

The YR IP44 series low voltage asynchronous motor is designed for reliable operation in demanding industrial environments. Featuring IP44 protection, robust construction, and stable performance, it is suitable for applications requiring high starting torque and smooth operation, such as conveyors, fans, pumps, and compressors.

YR IP44 Series Low-Voltage Three-Phase Motor asíncrono: Efficient and Reliable Industrial Power Solution

In the field of industrial power transmission, the YR IP44 Series Low-Voltage Three-Phase Asynchronous Motor stands out for its exceptional starting performance and stable operational characteristics. Designed to handle heavy-duty applications, this series has become the preferred power solution for industrial machinery and equipment requiring reliable startup and continuous operation across multiple sectors.

With robust construction, high efficiency, and adaptability to harsh industrial environments, the YR IP44 series ensures consistent performance, energy savings, and extended motor life, making it an ideal choice for industries such as manufacturing, processing, material handling, and automation systems.

YR IP44 Series Low-Voltage Three-Phase Asynchronous Motor: Efficient, Reliable Industrial Power Solution

Product Overview

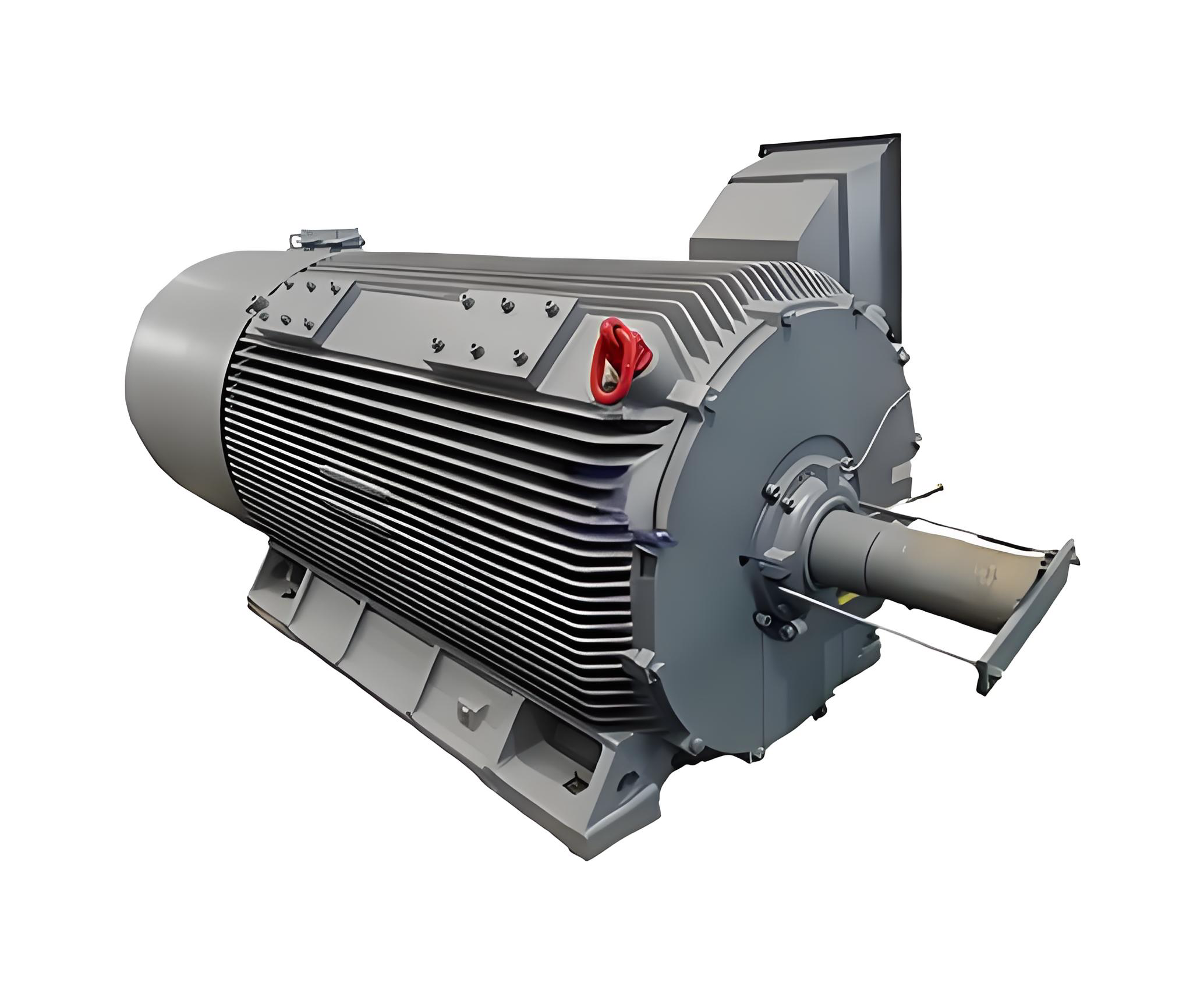

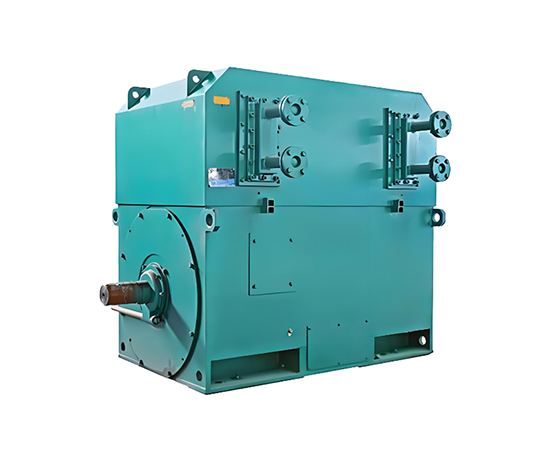

The YR IP44 Series Low-Voltage Three-Phase Asynchronous Motor is a fully enclosed wound-rotor three-phase motor, engineered with advanced electromagnetic design and high-calidad materials. It features high starting torque, excellent speed regulation, reliable operation, and easy maintenance. This series strictly complies with JB/T 7119-2022 standards for YR series (IP44) wound-rotor three-phase motors, with power ratings and installation dimensions meeting IEC international standards for easy integration and replacement in industrial equipment.

The YR IP44 series operates at a rated voltage of 380V and a frequency of 50Hz, with power ranging from 4 kW to 315 kW and frame sizes from 132 to 355, suitable for a wide variety of industrial applications. Designed as the core of industrial power, it drives heavy machinery such as compressors, crushers, hoists, fans, pumps, and conveyor systems. Its enclosed design ensures dependable performance in harsh industrial environments, making it ideal for mining, machinery, petrochemical, power generation, and general industrial applications.

Core Technical Features

- Exceptional Starting Performance: The wound-rotor design provides high starting torque at low starting currents, reducing grid impact. This design solves the problem of insufficient torque in standard squirrel-cage motors under heavy load start conditions.

- Flexible Speed Control: The wound-rotor structure allows adjustable speed through external resistors, enabling smooth speed regulation for different operating requirements.

- High Efficiency and Electrical Performance: Equipped with B or F class insulation, low noise, and stable operation, the motor ensures long service life and energy savings.

Technical Specifications

| Parameter | Specification |

|---|---|

| Tamaño del marco | H132–H355 |

| Potencia nominal | 4 kW – 315 kW |

| Tensión nominal | 380V (options: 220V, 400V, 415V, 660V, 1140V) |

| Frecuencia nominal | 50Hz (optional 60Hz) |

| Clase de protección | IP44 |

| Clase de aislamiento | B or F |

| Método de refrigeración | IC411 (TEFC) |

| Duty Type | S1 (continuous duty) |

| Mounting Options | IMB3, IMB5, IMB35, standard installations |

Performance Characteristics

- Excellent Starting: High torque at low inrush current, suitable for heavy loads.

- Wide Speed Range: Smooth speed control via rotor resistance adjustment.

- Baja vibración y ruido: Optimized design ensures stable operation.

- High Power Factor: Reduces reactive power, improving grid efficiency.

Construction and Configuration

- Enclosure: IP44 protection against solid objects >1mm and water splashes.

- Stator: Reliable B or F class insulation, varnished and securely fixed.

- Rotor: Wound rotor with high-quality materials, connected via slip rings for external resistor control.

- Junction Box & Cooling: Flexible wiring options; IC411 full-enclosure self-cooling ensures heat dissipation and continuous operation.

Applications

- Heavy Industry: Mining (crushers, hoists), Metallurgy (rolling mills, compressors), Power plants (fans, pumps).

- General Industrial Equipment: Compressors, pumps, conveyor systems, machine tools.

- Special Scenarios: High starting torque requirement, limited feeder capacity, frequent starts, adjustable-speed applications.

Product Advantages and Value

- Reliable Operation: Robust construction, high-quality insulation, adaptable to harsh environments.

- Energy and Cost Efficiency: Reduced starting current, higher startup capability, long service life, lower total cost of ownership.

- Maintenance-Friendly: Enclosed structure, modular components, long maintenance intervals.

Installation & Usage Guidelines

- Operate in environments below 1000m altitude and ≤40°C.

- Ensure sufficient space around motor for cooling and maintenance.

- Proper startup requires rotor resistance insertion; suitable for coupling, gear, or belt drives.

- Follow nameplate and wiring diagrams for safe electrical connection.

Quality Assurance and Support

- Complies with JB/T 7119-2022 and national standards.

- Each motor undergoes strict testing and factory performance validation.

- Comprehensive after-sales support: professional technical consultation, rapid response, long-term service.

The YR IP44 Series Low-Voltage Three-Phase Asynchronous Motor offers excellent starting performance, flexible speed control, and reliable operation, making it a premier choice for industrial power solutions. Selecting the YR IP44 series ensures dependable equipment performance and professional technical support, driving energy-efficient industrial operations and sustainable development.

Red pública de seguridad de Shaanxi nº 41032502000206

Red pública de seguridad de Shaanxi nº 41032502000206