摘要:

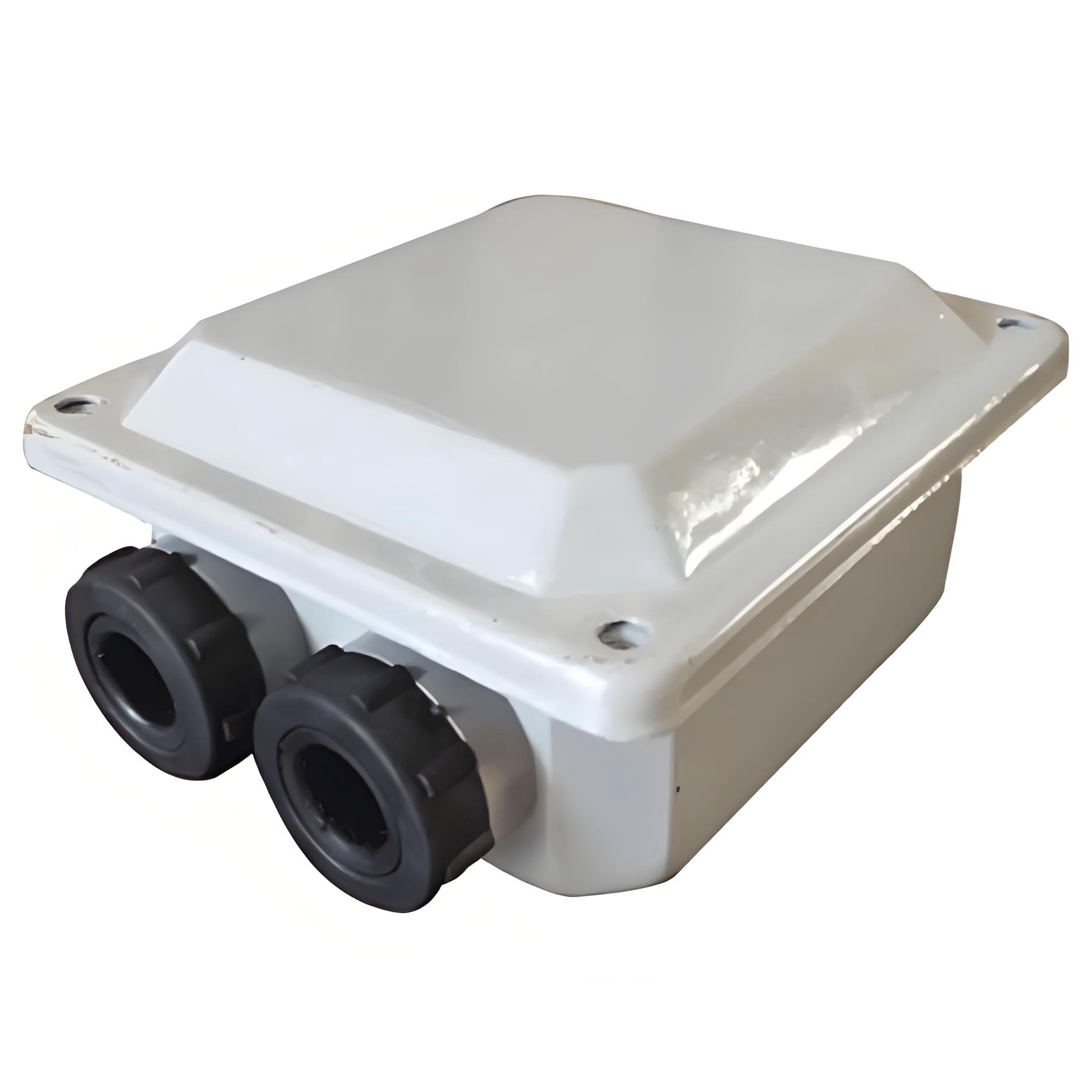

The motor junction box is designed to safely house electrical connections for electric motors. It ensures reliable wiring, protects against dust and moisture, and enhances the motor's overall safety and operational efficiency.

SIMO Motor Junction Boxes: Core Connection for Safe Motor Operation

In complex motor systems, junction boxes serve as critical hubs for power input and distribution. Their performance and calidad directly affect the stability and safety of the entire motor system.

SIMO Motor junction boxes are essential components that handle power cable entry, internal wiring, and environmental protection for electrical contacts. As the connection bridge between the motor and external power, SIMO junction boxes are manufactured with high-quality materials y precision engineering, offering high protection levels, excellent insulation, reliable connections, and easy installation, making them suitable for a wide range of industrial motors and motors operating in special environments.

Product Overview and Core Functions

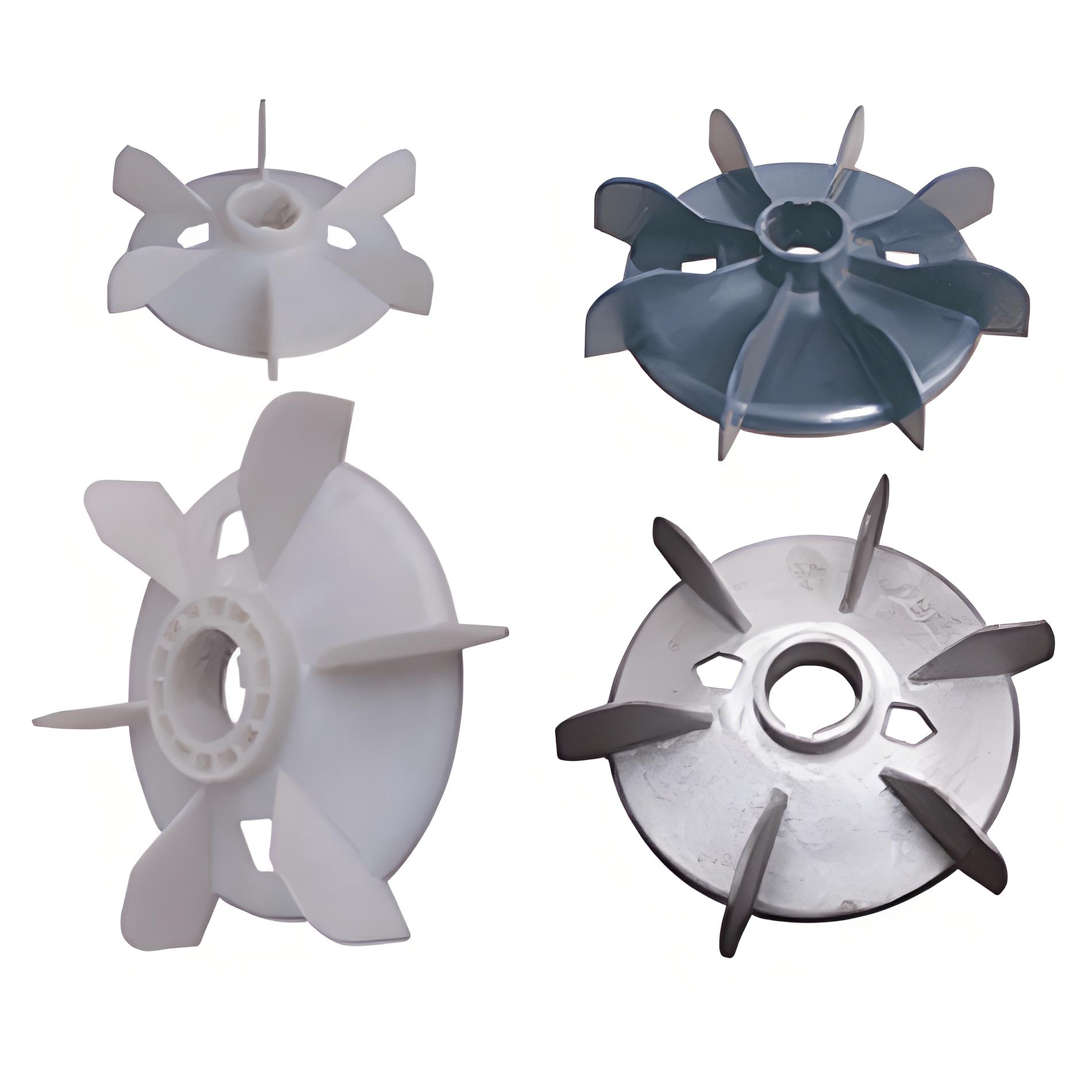

SIMO Motor junction boxes are installed on the exterior of the motor frame and serve as the core component of the motor power access system, responsible for power entry, internal connections, and safety protection. Optimized design and material selection ensure safe and stable power supply under various operating conditions.

Core Functional Components:

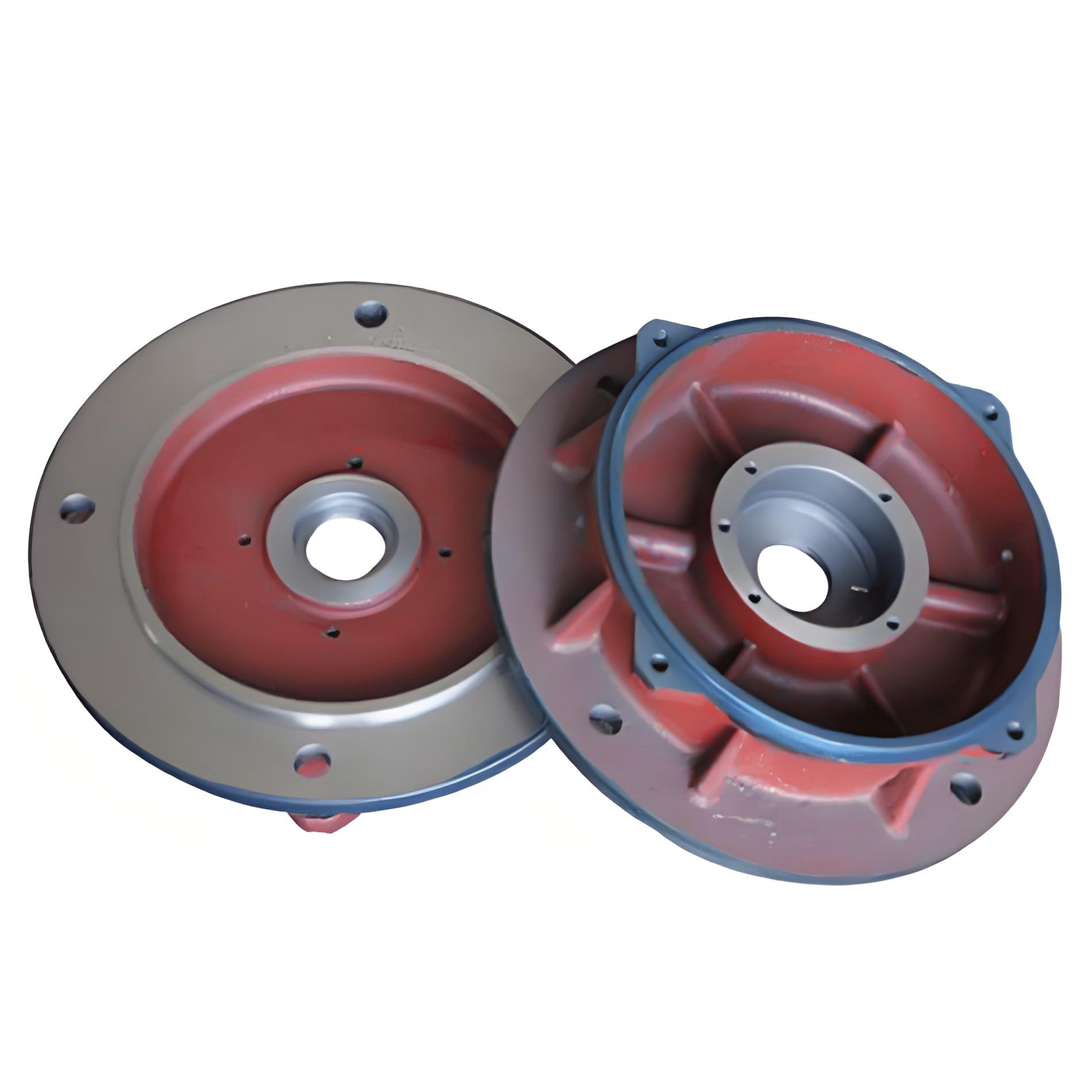

- Box Body: Constructed from high-strength cast iron or aluminum, providing solid mechanical protection and effective heat dissipation.

- Sealing System: Equipped with professional gaskets and cable interfaces to achieve IP55 or higher protection, preventing dust, moisture, and contaminants.

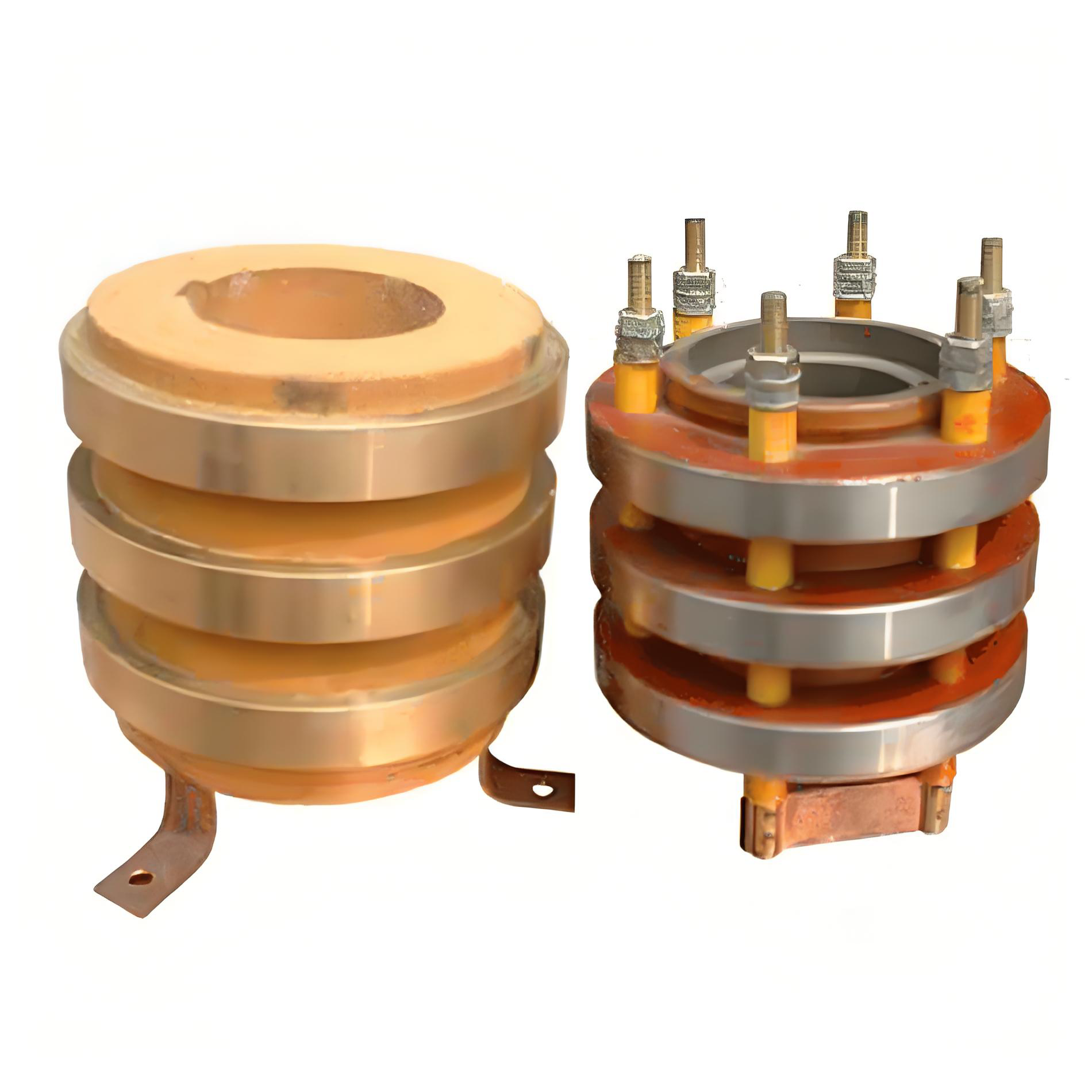

- Connection Terminals: High-quality conductive materials ensure low-resistance connections and reliable electrical continuity.

- Internal Space: Optimized layout allows sufficient room for wiring and easy installation or maintenance.

Key Technical Features and Performance Advantages

SIMO junction boxes integrate innovative engineering design y strict quality control, offering significant performance benefits:

1. Superior Protection

- Multi-Layer Sealing: Precision seals at cable entry points and gasketed cover prevent ingress of water, dust, and corrosive media.

- High Protection Level: Standard IP55, customizable higher levels, suitable for humid, dusty, or harsh industrial environments.

- Weather Resistance: Special surface treatment allows operation in -25℃ to +40℃ ambient conditions.

2. Reliable Electrical Performance

- High Insulation Materials: Use of high-grade engineering plastics or metal casing with insulation liner ensures electrical safety.

- Optimized Wiring Layout: Terminals arranged to maintain adequate clearance and creepage distance, reducing risk of arcs and short circuits.

- Reliable Grounding: Dedicated grounding terminals ensure operator safety and motor protection.

3. Easy Installation and Maintenance

- Spacious Internal Design: Provides ample space for wiring and maintenance operations.

- Modular Design: Certain models feature modular structures for quick replacement and reduced downtime.

- Flexible Installation Options: Supports multiple mounting methods for different motor types.

Technical Parameters and Specifications

| Parameter | Specification |

|---|---|

| Applicable Motor Power | 0.75 kW – 1000 kW (model-dependent) |

| Protection Level | IP55, IP56 (higher customizable) |

| Clase de aislamiento | F, H (model-dependent) |

| Tensión nominal | 380V, 660V, 1140V (per motor specification) |

| Rated Current | Configured according to motor power |

| Operating Temperature | -25℃ to +40℃ |

| Cable Interface | PG9–PG48, M20–M60 (multiple options) |

| Box Material | Cast iron, cast aluminum, engineering plastic |

Product Series and Features:

- Standard Junction Box: Balanced performance and cost-effective, ideal for most industrial motors.

- Explosion-Proof Box: Higher protection and specialized explosion-proof design for hazardous environments.

- Corrosion-Resistant Box: Special surface treatment and corrosion-resistant materials for chemical or marine environments.

- High-Temperature Box: Heat-resistant materials and design for metallurgy, boiler, and high-temperature applications.

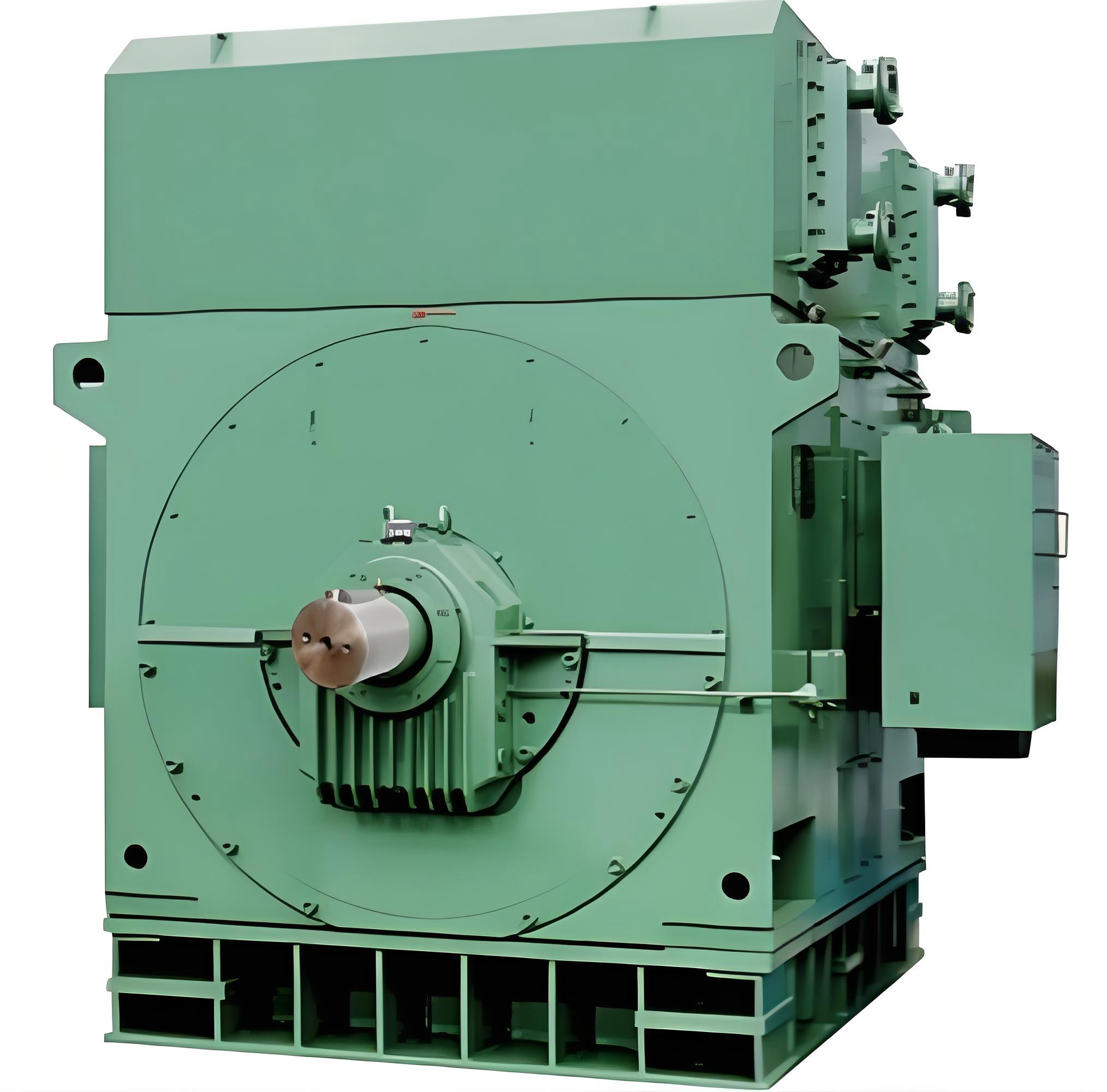

Application Areas and Industry Solutions

SIMO Motor junction boxes provide reliable performance and versatile designs for a variety of industrial applications:

1. Industrial Manufacturing

- Power Industry: Boiler fans, pump motors, and generators, ensuring stable operation.

- Metallurgy: Steel rolling equipment, smelting fans, and conveyor motors, resistant to high temperature and dust.

- Building Materials: Cement mills, fans, and conveyors requiring robust protection.

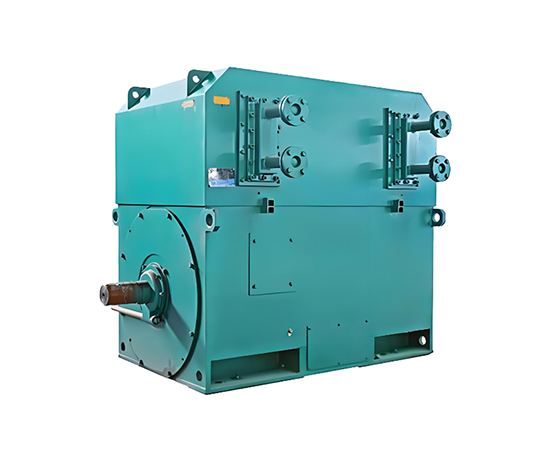

2. General Industrial and Civil Use

- Fans and Pumps: Centrifugal, axial, and various pump motors.

- Industrial Production Equipment: Machine tools, compressors, and conveyor motors.

- Water Treatment Systems: Sewage and water supply motors operating in humid conditions.

3. Special Environment Applications

- Hazardous Locations: Chemical plants, underground mines with explosion-proof requirements.

- High Humidity Areas: Underground projects, offshore platforms requiring corrosion resistance.

- Outdoor Installation: Motors exposed to rain, wind, and UV.

Selection and Installation Guide

1. Selection Considerations

- Motor Parameters: Match junction box to motor model, power, voltage, and current.

- Environment: Temperature, humidity, dust, corrosive substances.

- Cable Specifications: Size and quantity determine interface and internal space.

- Special Requirements: Explosion-proof, high-temperature, or corrosion-resistant needs.

2. Installation Tips

- Sealing: Ensure gaskets are properly placed, cover tightened evenly for full protection.

- Cable Entry: Use suitable cable glands for reliable sealing.

- Connection Quality: Secure terminals, maintain appropriate clearance and creepage distance.

- Grounding: Ensure proper grounding for safety.

Maintenance and Troubleshooting

1. Routine Maintenance

- Regular Inspection: Check seals, cable connections, and internal condition.

- Cleaning: Remove dust and oil for proper heat dissipation.

- Seal Replacement: Replace worn gaskets to maintain protection.

2. Common Issues

- Seal Failure: Replace gasket or reinstall correctly.

- Loose Connections: Check and tighten regularly.

- Insulation Degradation: Clean and dry to restore insulation performance.

Service and Support

- Technical Consultation: Product selection and application guidance.

- Customized Solutions: Tailored designs for unique applications.

- After-Sales Guarantee: Quality assurance and support for worry-free operation.

- Inventory Assurance: Stock availability for urgent requirements.

SIMO Motor junction boxes combine scientific design, premium materials, and precision manufacturing, making them an ideal solution for motor power connections. Suitable for both standard industrial environments and harsh conditions, they provide reliable performance and long service life.

Choosing SIMO Motor junction boxes ensures secure connections and lasting operational reliability, supporting your equipment with optimal power distribution solutions.

Red pública de seguridad de Shaanxi nº 41032502000206

Red pública de seguridad de Shaanxi nº 41032502000206